When it comes to occupational health and safety, new real-time dust monitoring such as the XD ONE Portable Dust Monitor can help to make decisions for the hierarchy of controls.

In this e-book we explain how the arrival of affordable, real-time monitoring, and both wearable and portable dust monitoring technologies promote this new awareness of the dangers of dust in a far broader range of working environments.

Employers and the health and safety community are now shifting their attention. Where they’ve traditionally focused on safety, they now look at the major impacts on long-term health associated with working in hazardous environments.

There’s also an increasing awareness of the range of industries that can present long-term health hazards through the inhalation of dangerous dust particles, from traditional industrial environments to commercial activities.

The HSE are reporting an estimated 1.4 million people in the UK report ‘lung or breathing problems that were caused or made worse by work’ – and whilst it’s great that people are starting to pay more attention to this issue, there’s plenty of room for improvement.

Whilst financial costs of lung diseases effect both businesses and individuals, respiratory diseases are more than just an economic drain. It’s a personal tragedy, and there are a whole raft of occupations and jobs where people are exposed to dangerous dust across the world.

However, through the hierarchy of controls, businesses can determine the most effective solutions in order to keep workers protected from dangerous dust exposure.

Knowing that dangerous dust exists, knowing its effects are potentially lethal, and knowing that the damage it causes is preventable, only takes you so far. Knowing how to prevent that harm is what matters, and this is how the hierarchy of controls can help businesses become more efficient, by understanding how effective each method is in benefitting the workforce.

Fortunately, new accurate, real-time, fixed, wearable and portable dust and silica monitoring sensors are leading the detection charge across every use case. By precisely reading the real-time dust load in any given environment, and the enemy now ‘visible’, businesses can begin to apply the hierarchy of controls in a far more meaningful way.

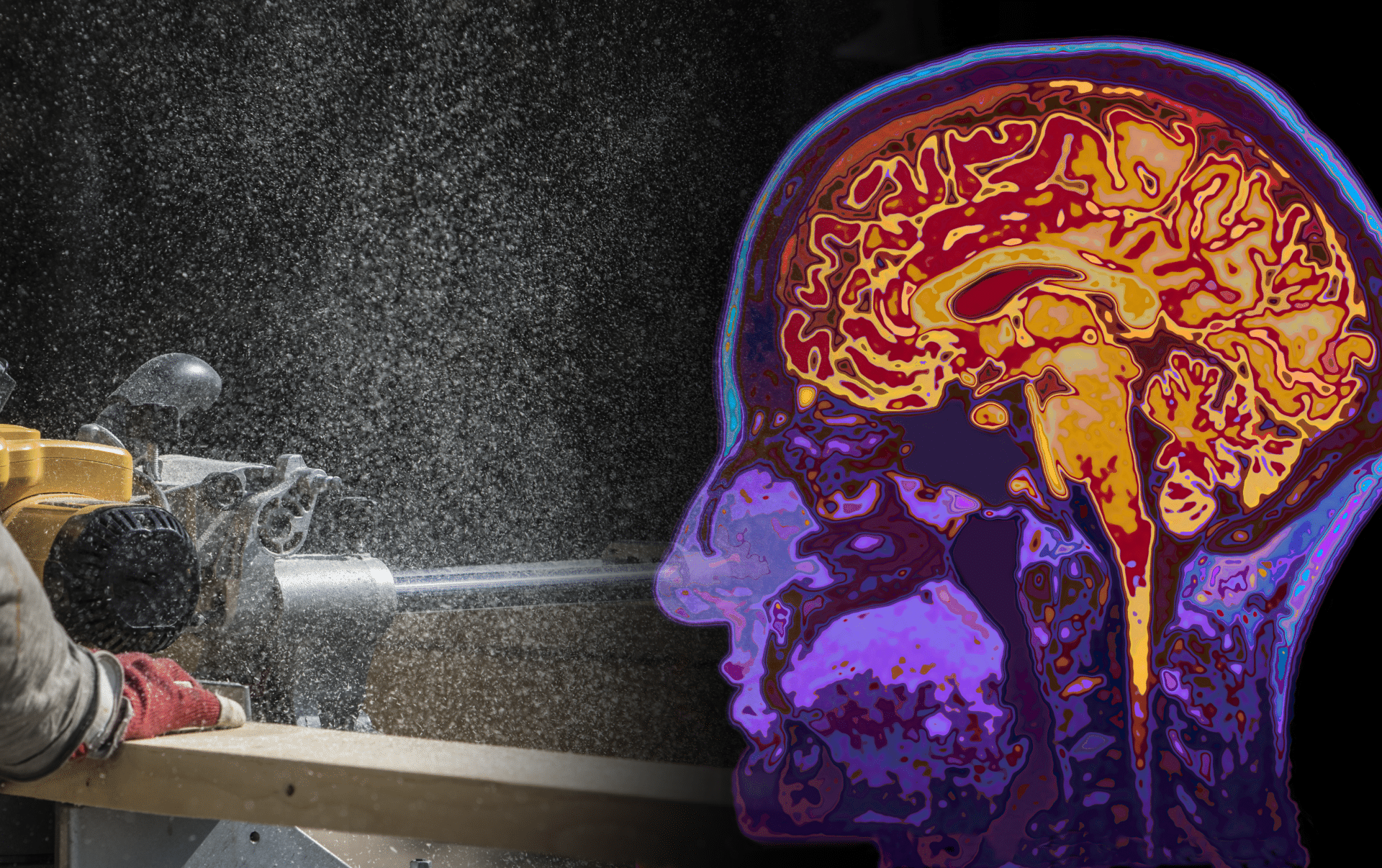

As if the known dangers of exposure to harmful respirable dusts weren’t bad enough, new research is showing that long-term exposure to ambient air pollution is associated with a far wider range of diseases and highlights the importance of particulate monitoring.

Not only are 1.4 million people in the UK reporting ‘lung or breathing problems that were caused or made worse by work,’ and 12,000 people dying every year due to occupational lung diseases, evidence is mounting to show that airborne pollution also causes dementia, strokes and skin cancer.

The study, conducted in the USA and first published in the journal Stroke is titled “Long-Term Exposure to Fine Particulate Matter, Residential Proximity to Major Roads and Measures of Brain Structure“.

Examining the brains of more than 900 people over 60 years old, it revealed that long-term exposure to fine dust causes both brain atrophy (brain shrinkage) and leads to an increased risk of stroke and other disease.

Not only is this news alarming for those who live near busy roads, it also draws attention to the added dangers faced by those working in conditions, and with materials, they may have previously thought safe.

For example, welders, who, despite now using supposedly less dangerous materials and working in spaces where local exhaust ventilation (LEV) is employed, seem to be vulnerable to a far wider range of illnesses than previously thought.

As the report highlighted, even limited exposure of fine dust particles can lead to the heightened risk of cerebrovascular disease and cognitive impairment.

Benjamin Howell on the Fabricator.com says, ‘at the nanolevel, invisible to the human eye, the concentration of particulate matter can pose a great risk to welders. Studies show that welding fume particulates are mostly smaller than 0.1 micrometer, which makes nearly all welding fume particles respirable. They can penetrate deep into the alveolate region of the lungs during inhalation and remain firmly fixed there.’

It’s not all bad news though.

By revealing far greater and far wider reaching dangers than previously acknowledged, the new research means the important issue of how best to protect people from damaging dusts is getting the attention it deserves.

The sheer weight of evidence amassing from the likes of The Journal of Cleaner Production, The British Medical Journal, and Harvard is forcing the hand of governments, regulatory bodies and employers. The necessary steps to protect not just their workers, but every one of us exposed to dangerous airborne pollutants, are being considered and taken. This includes controls, sensors and dust detectors, among other things.

What if a threat could be detected before it even became a threat? What if you could be alerted to the presence of even the smallest of damaging airborne dusts before they had the chance to damage health?

Leading H&S expert John Cairns says:

“The best thing is to detect the hazard before you’re exposed to the hazard. Before you’re exposed to the hazard or a high concentration. You can get the hell out of there, or with the way this new technology works you can set off ventilation systems to clear the area.

The whole ethos behind the Health and Safety Executive (HSE) is to reduce the risk to as low as is reasonably practicable. I think the XD ONE Portable Dust Monitor is adding to that – it’s enhancing the safety system.”

Real-time dust monitoring is an effective way at reducing the risk to workers in hazardous working environments. When combined with RPE, PPE and other equipment, the threats from dust and particle inhalation are reduced drastically. This has a big impact on worker health, morale and productivity.

Send us a message today to find out more about our work to help organisations like yours protect your people from the threat of damaging dust particles with sensors, dust detectors and systems tailored to your work environment.

The IOSH Construction Group Committee Construction Dust Survey makes for sobering reading. Firstly, it highlights the fact that much more needs to be done to increase awareness of the dangers of dust from an employees perspective:

“Dust causes a lower level of concern among employees than the more immediately noticeable dangers of construction, such as falls…they do not perceive it as a significant immediate risk to their wellbeing unlike falls from height, equipment etc.”

It also highlights a lack of awareness from the industry as a whole. Of 618 health and safety professional respondents, ‘44.6 percent thought that the industry gave little or no priority to the issue, and a similar proportion (42.4 percent) felt that it received the same priority as other health issues.’

And even when awareness exists, the report found that compliance is weak.

‘54.0 percent of respondents indicated that workers sometimes fail to follow prescribed methods of work. Over a third of respondents (36.2 percent) indicated that this happened most or all of the time.’

So what’s going on? Why, even when employers and their onsite teams are in possession of the facts, do they too often choose to ignore the dangers posed by dust?

Dangers that lead to 10 deaths a week from lung cancer caused by silica dust, let alone the other illness and premature death from other cancers, silicosis, asthma and chronic obstructive pulmonary disorder (COPD).

You’ll be familiar with the concept of cognitive dissonance, ‘the state of discomfort felt when two or more modes of thought contradict each other’.

Like knowing smoking is bad for you, but continuing to smoke.

Like, “we know dust is dangerous but there’s no convenient, low-cost alternative to handling the risk. So we’ll stick with what we’ve always done.”

Barriers to change

There’s a lot to learn in the Construction Dust Survey.

More than anything, it’s highlighted that despite being increasingly aware of the dangers, people aren’t taking action.

Somehow, industry has convinced itself that the culture and adoption of, the management of, and the cost, complication and general hassle of creating a safe working environment is more trouble than just leaving things be.

Here are just some of the barriers to change noted in the survey:

Culture: The culture of the industry, and its ‘traditional’ view of dust as an expected or normal part of construction work, can be a significant barrier.

Use: Workers often view the controls as cumbersome, impractical, affected by poor maintenance or giving rise to other risks. This deters use.

Employees: Implementing controls effectively depends on good management and supervision. Operators generally choose not to use controls.

Management arrangements: In general, the industry does not seem to manage dust control issues adequately. Comments refer to a link between the management priority given to this issue and the corresponding conditions found on-site.

Cost: Dust control is often viewed as labour-intensive, expensive, time-consuming and a nuisance that slows work.

‘The industry creates this risk. It now needs to acknowledge it, own it and deal with it.’

It somehow seems that as awareness increases, industry seems to think a cultural shift towards safer working environments will run its own natural course over time.

“It is like wearing a hi-vis 15 years ago or hard hats. It took years for the culture to change.” says a contributor to the report.

Fortunately, we’ve taken a far more proactive approach.

What if we could fast track that safer working environment?

What if that cognitive dissonance could be eased instantly and increased awareness could be achieved overnight? And what if you only ever had to use dust control methods when you actually needed them?

It’s hard to not be aware of something when an alarm is screaming in your ears and bright lights are flashing.

Well, here’s the thing.

A low-cost, simple-to-use, personal alarm would help solve the problem overnight.

All those adoption and implementation objections, all the excuses and all those barriers to change would evaporate. Instantly.

And here’s another thing.

That low-cost, simple-to-use, personal alarm exists.

It’s new and it’s here.

The XD ONE Portable Dust Monitor.

Get in touch today and we’ll tell you everything you need to know about how real-time dust and silica monitoring technology can protect your workers from the threat of preventable disease.