Gas detection technology to modernise the tunnelling industry

Did you make it to the BTS 2020+1 Conference and Exhibition in London at the end of September? 800+ tunnelling professionals in attendance and 55+ global tunnelling brands exhibiting over two days of serious tunnel talk.

If you did, then you’ll probably be aware that while discussions amongst tunnelling design, construction, and operation and maintenance professionals were initially concerned that the number of UK tunnelling projects seem to be in decline, what actually emerged from the event was a feeling of optimism.

With more London Underground projects in the pipeline, other UK underground train projects planned and talk turning to creative ways that tunnelling can be used to mitigate the effects of climate change – what began as a rather gloomy outlook soon turned far more positive as the conversations turned to fresh opportunities.

The Toronto example

Take the scale and success of Toronto’s PATH for example. This gargantuan tunnelling project includes:

- 30 kilometres of restaurants, shopping, services and entertainment

- Six subway stations, three major department stores, nine hotels, and Toronto’s busiest transit hub – Union Station

- Accommodating more than 200,000 business-day commuters as well as tourists and residents

- 3.7 million square feet of retail space

- 1,200 restaurants, shops and services $1.7 billion in sales annually

- 4,600 jobs are located in the PATH

- $271+ million in federal, provincial, and municipal tax revenue annually

Constructed over the last 100 years to allow the city to function successfully in the face of bitterly cold winters with huge volumes of snowfall, PATH shows that there’s clearly potential for innovative problem solving to create similar underground living, working and socialising environments.

Instead of protecting people from the effects of extreme cold, new designs might protect us from extreme heat as the climate emergency gathers pace.

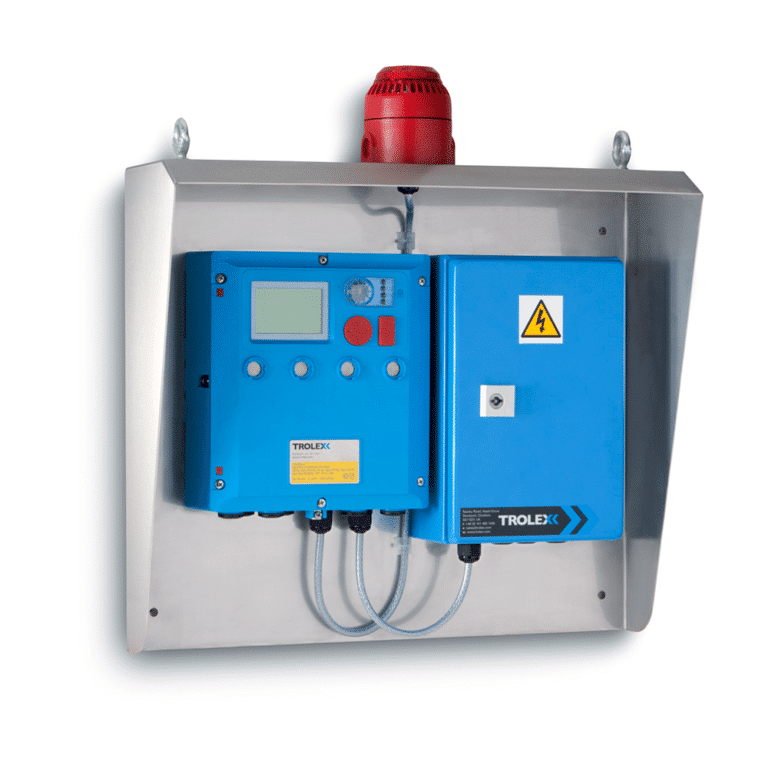

The Trolex Sentro 8

Internationally approved and certified, the Sentro 8 is designed to function in the world’s most dangerous working environments, allowing you to scan for up to eight different gases simultaneously.

In short: All the detection you need for complex mining and industrial applications in a single device.

Group 1 IS (intrinsically safe) compliant – low power consumption, zero sparking and certified for the most dangerous of industrial environments, the Sentro 8 protects your workers from a broad range of environmental threats and also alerts you to ambient changes.

- Multi-gas detection – Scan for up to eight different gases simultaneously.

- Multi-purpose – Quickly configure up to four ports for a range of ambient temperature, ventilation, air velocity or other environmental monitoring.

- Real-time – Quick-fit, pre-calibrated input sensing ‘eModules’ to detect a range of toxic and flammable gases in real-time.

- Scalable – Network your SensorStations to a master computer and expand the system as your site grows.

When safety demands that you monitor for multiple gasses or other environmental conditions – all at the same time – use the Trolex Sentro 8.

Future-proofing the tunnelling industry

Whatever the challenge. Wherever in the tunnelling world that challenge exists. Whenever in the future that challenge presents itself – we’re ready to take it on – to protect your workers from dangerous gases and particulates and to make tunnelling as safe as it can possibly be.

Contact us today using the contact form below and we’ll tell you everything you need to know about real-time toxic and flammable gas detection and how to keep your people safe on your next tunnelling project.