‘PM’ or particulate matter, also known as particle pollution is the term for a mixture of solid particles and liquid droplets found in the air.

It’s estimated that air pollution is linked to 43,000 deaths per year in the UK. Worldwide, at least 7 million people die each year from exposure to air pollution, with 91% of the worldwide population living in locations where the air quality exceeded the World Health Organisations (WHO) air pollution guidelines.

These guidelines state that that annual average concentrations of PM2.5 should not exceed 5 µg/m3 and PM10 should not exceed 15 µg/m3 (both for 24-hour periods). According to the WHO, ‘fine particulate matter at PM2.5 can penetrate through the lungs and further enter the body through the blood stream, affecting all major organs’. Exposure to dust at PM2.5 can cause serious disease to the respiratory system, such as lung cancer and COPD, and also can effect cardiovascular diseases, such as a stroke.

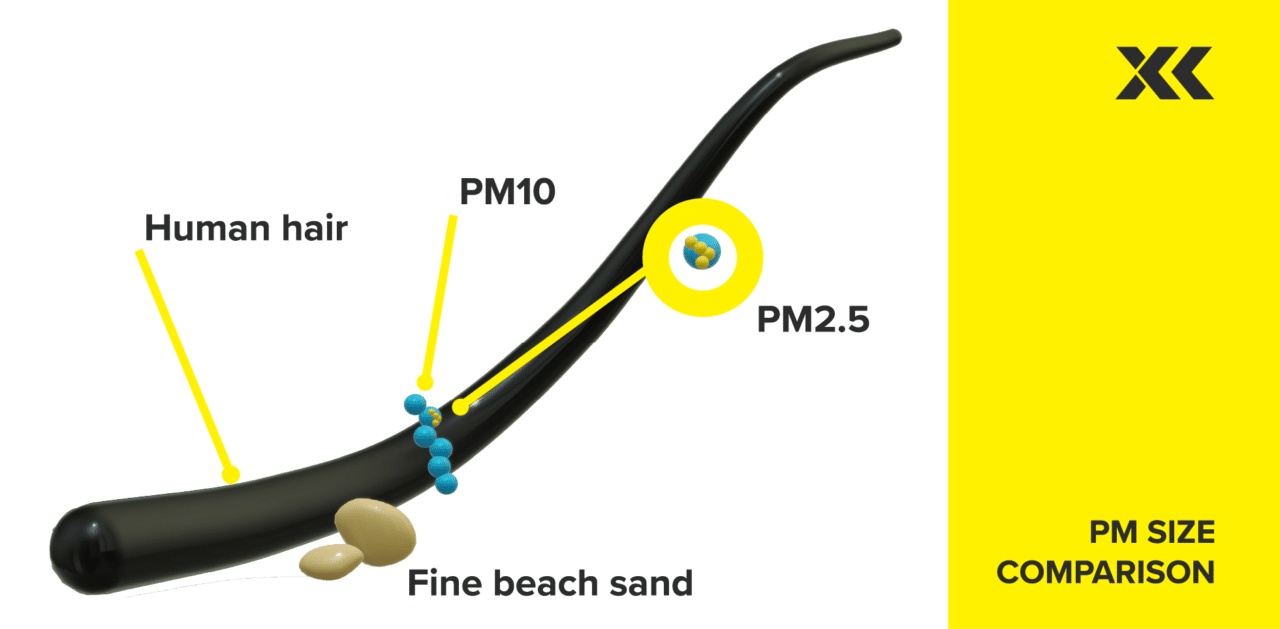

The image below demonstrates PM2.5 and PM10 size in comparison to a single human hair and a grain of sand.

The Department for Environment Food & Rural Affairs (DEFRA), the UK government ministerial department for environment protection, have also highlighted the severity of exposure to air pollution. This growing concern for the UK government estimated in 2010 that the cost of health impacts of air pollution was likely to exceed estimates of £8bn to £20bn.

Although between 2005 and 2022, the UK’s PM2.5 emissions decreased by 41%, emission levels have been relatively steady with small annual fluctuations in the last decade. Industrial combustion is a major source of PM emissions, as well as emissions from industrial production also playing a major part, which can be linked to heavy-dust industry where hazardous particulates can become airborne. Despite some reductions in PM emissions, the threat still very much remains.

A solution to this is real-time dust monitoring. Real-time particulate monitoring allows people in heavy dust loading environments, including industrial applications, to not only understand, but alert them instantaneously when they are exposed to dangerous levels of air pollution. For example, our AIR XD Dust Monitor can alert people in real-time when legislative levels of µg/m3 are breached, over a time-weighted average (TWA) 8-hour period, for both PM2.5 and PM10.

This technology not only offers a simple solution to individuals at high risk of exposure to air pollution by providing instant alerts, but also can help to prevent exposure in the future, as at-risk individuals can learn exactly when and where exposure to air pollution is highest and will likely occur. Thanks to real-time monitoring, both in the UK and Worldwide, we can reduce exposure to air pollution.

In an ideal world, the risk of dangerous airborne particles simply wouldn’t exist in the workplace. We cannot understate how important respiratory protective equipment (RPE) is, even compared to all the other safety technologies available.

The proper application of the Hierarchy of Controls (HoC), though Elimination, Substitution, Engineering, Administration and personal protective equipment (PPE) would mitigate the threat and make sure that everyone was properly protected.

The unfortunate reality is that many workers still face threats from a wide range of hazardous dust and particulates, such as silica, construction dust, fibreglass, wood, asbestos and many more. Respiratory protective equipment is one of the most effective safety technologies against silica dust and other harmful inhalants.

While every stage of the HoC can play an important role in helping to make workplaces safer, it’s the final stage, the PPE/RPE – the provision and proper wearing of suitably selected and fit tested RPE – that presents the biggest challenge.

Why?

Because too often, RPE fails to provide the protection that providers or wearers think it does.

The IPPI test is a good way to make sure the RPE and PPE you provide – or have been provided – is fit for purpose. Before entering any environment where there’s a risk of harmful dust inhalation, it’s important to check whether the RPE is:

The Construction Dust Partnership (an industry collaboration that helps help construction industry contractors, employers, operatives and others manage the risk of exposure to dusts and raise awareness) says, ‘any gaps around the RPE’s edges allow the contaminant-laden air to pass straight to the nose/mouth and be inhaled into the lungs.’

For example, did you know that beards or stubble can severely impact the performance of RPE?

‘If the wearer has stubble where the RPE seals to the face, this will make an adequate seal between the skin and the RPE impossible. A lack of knowledge or understanding on how to wear RPE correctly can often lead to an unrealistic expectation of protection.’

In other words, people are working with a false sense of security. Not only must the RPE be fit for purpose, but proper training and guidance must be provided on its use – like any other piece of health and safety technology or equipment. Better would be for checks to be made before entering areas with hazardous substances.

There’s nothing more dangerous than thinking you’re safe when in reality you’re not. When you’re labouring under the illusion that your RPE is protecting you from harm and all it’s doing is placing you squarely in harm’s way, it’s a big problem.

“People are not so good at assessing exposure to a risk,” says risk perception expert Ann Bostrom, of University of Washington.

It’s something we’ve seen clearly during the Covid pandemic. Masks acting as signifiers of safety rather than providing genuine protection.

A dangerous combination of availability and confirmation bias, the psychology is explained in this Forbes article, drawing comparisons between respiratory protective equipment and seatbelts. It cites a report that shows people drive faster and more recklessly when they wear seatbelts. The same applies to cyclists riding less cautiously when wearing helmets.

So what’s the answer? If industry is consistently failing to apply the Hierarchy of Controls well enough to protect workers, or even worse, lulling workers into a dangerously false sense of security, what can businesses do to properly protect their people?

The answer is surprisingly simple.

Real-time dust monitoring that gives you an accurate, realtime understanding of the dust threat you and your workers face.

Properly detecting previously unseen and undetectable threats – seeing it as a real danger, not abstract – allows you to properly challenge it. And in the process, your RPE reclaims its proper protective value – a specific, contextual and essential value.

To be clear, dust monitoring is not a reason to not wear RPE and PPE, but it can make sure you’re aware when the environment changes and whether your equipment is appropriate for the situation you find yourself in.

Instead of being taken for granted, worn out of habit, ‘just in case’ or ‘because that’s the way we do it,’ RPE transforms from dangerous IPPI to safe APPW.

Instead of IPPI equipment, APPW is respiratory protective equipment that’s:

Get in touch today to find out more about how our new AIR XD Dust Monitor, XD ONE Portable Dust Monitor, XD1+ Personal Dust Monitor and AIR XS Silica Monitor – accurate, simple to use, easy to maintain, real-time particulate detection technology – helps your teams use their RPE more effectively.