New studies from charity ‘Asthma and Lung UK’ (ALUK) found that lung disease deaths in the UK are the highest in Western Europe.

The staggering statistics have prompted an expanded approach towards research and development of lung diseases from ALUK.

ALUK’s studies show that cases of lung disease related deaths in the UK have been on the rise for the past 20 years.

It is reported that 500,000 people in the UK died from deaths relating to lung diseases over a seven-year period.

In 2018 alone, 84,721 respiratory deaths were recorded in the UK.

The charity has described the state of lung health in the UK as ‘shameful’, stating the need for improved research and development solutions to the problem.

After its relaunch in February, ALUK established a new five-year strategy upon the results of the study.

Lung diseases are currently the third most common cause of death in the UK and it’s currently costing the NHS £9 billion every year.

Despite this, lung-related health care is receiving less than 2% of public funding.

It is evident that the seriousness of lung problems in relation to other diseases is not taken as seriously, despite what we are seeing from the data.

A predominant factor in the poor state of the nation’s lung health is that people believe lung conditions aren’t life-threatening. This is a major misconception.

Through spreading awareness of how ‘shameful’ lung health is in the UK, this misconception can be dispelled.

ALUK aim to reduce lung disease deaths by 20% by 2027. When making everyone aware of these gruesome statistics, this can become a possibility.

The end goal is to provide support for everyone effected by all forms of lung disease.

ALUK’s solution to achieving this goal is through research and innovation.

Their aim is to expand their research and innovation programme so that £5 million is being invested into relevant research each year.

With the aim to “develop at least three new self-management tools” for 2 million people suffering with lung diseases, ALUK want to make training programmes and essential advice easily accessible to those who need it.

“By 2027, we will give 80% of people with lung conditions the opportunity to access our network of Breathe Easy support groups” states the ALUK Strategy to 2027.

With this, the strain on public healthcare is minimised and individuals are able to monitor their personal health through digitalised platforms and shared networks.

The statistics right now make for harrowing reading and harsh truths.

However, for ALUK, research and innovation is the solution for the future. By identifying the problem and acknowledging its severity and scale, goals can be achieved.

Through effective research and innovation lung disease deaths can become a thing of the past, not just in the UK, but worldwide.

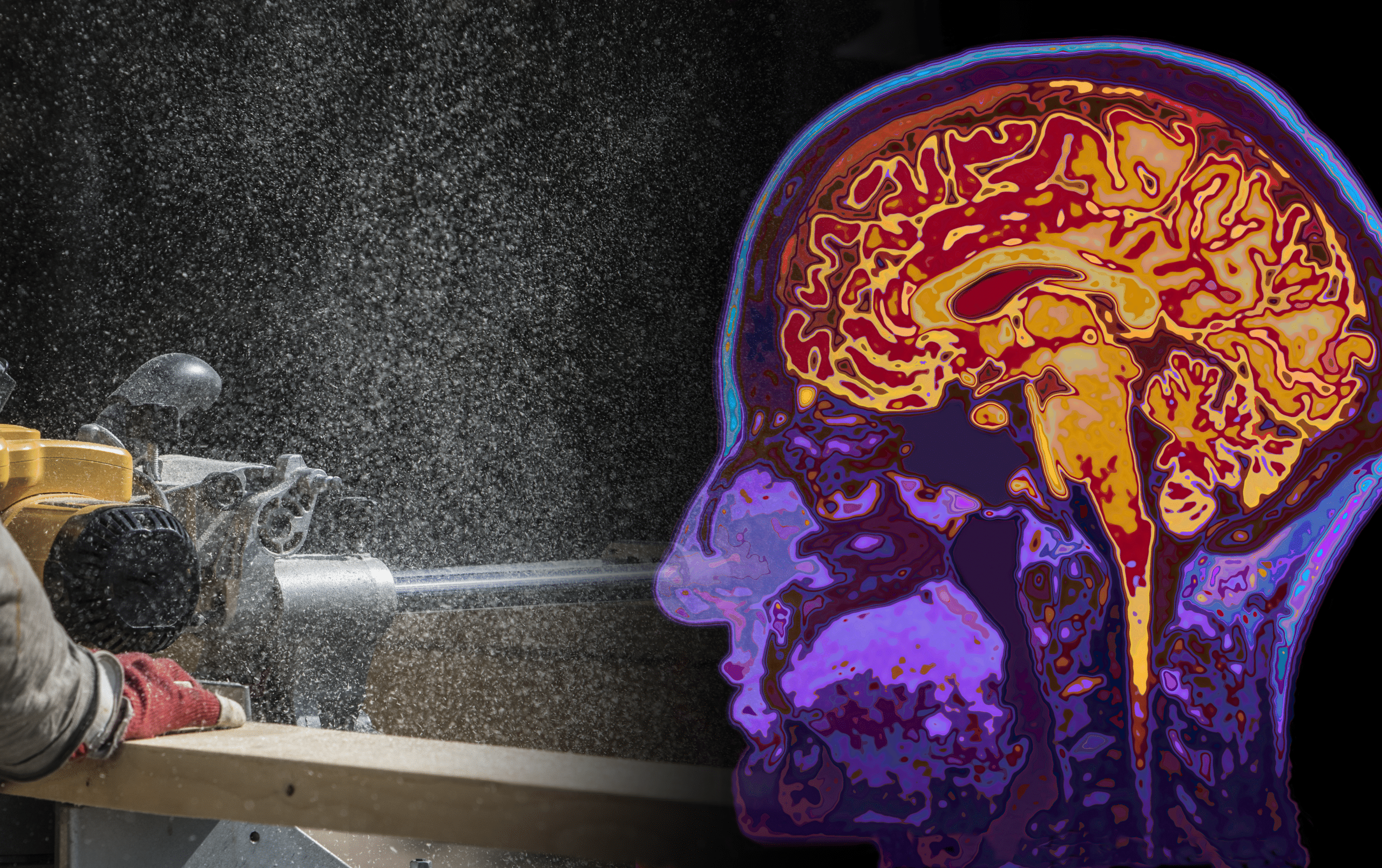

As if the known dangers of exposure to harmful respirable dusts weren’t bad enough, new research is showing that long-term exposure to ambient air pollution is associated with a far wider range of diseases and highlights the importance of particulate monitoring.

Not only are 1.4 million people in the UK reporting ‘lung or breathing problems that were caused or made worse by work,’ and 12,000 people dying every year due to occupational lung diseases, evidence is mounting to show that airborne pollution also causes dementia, strokes and skin cancer.

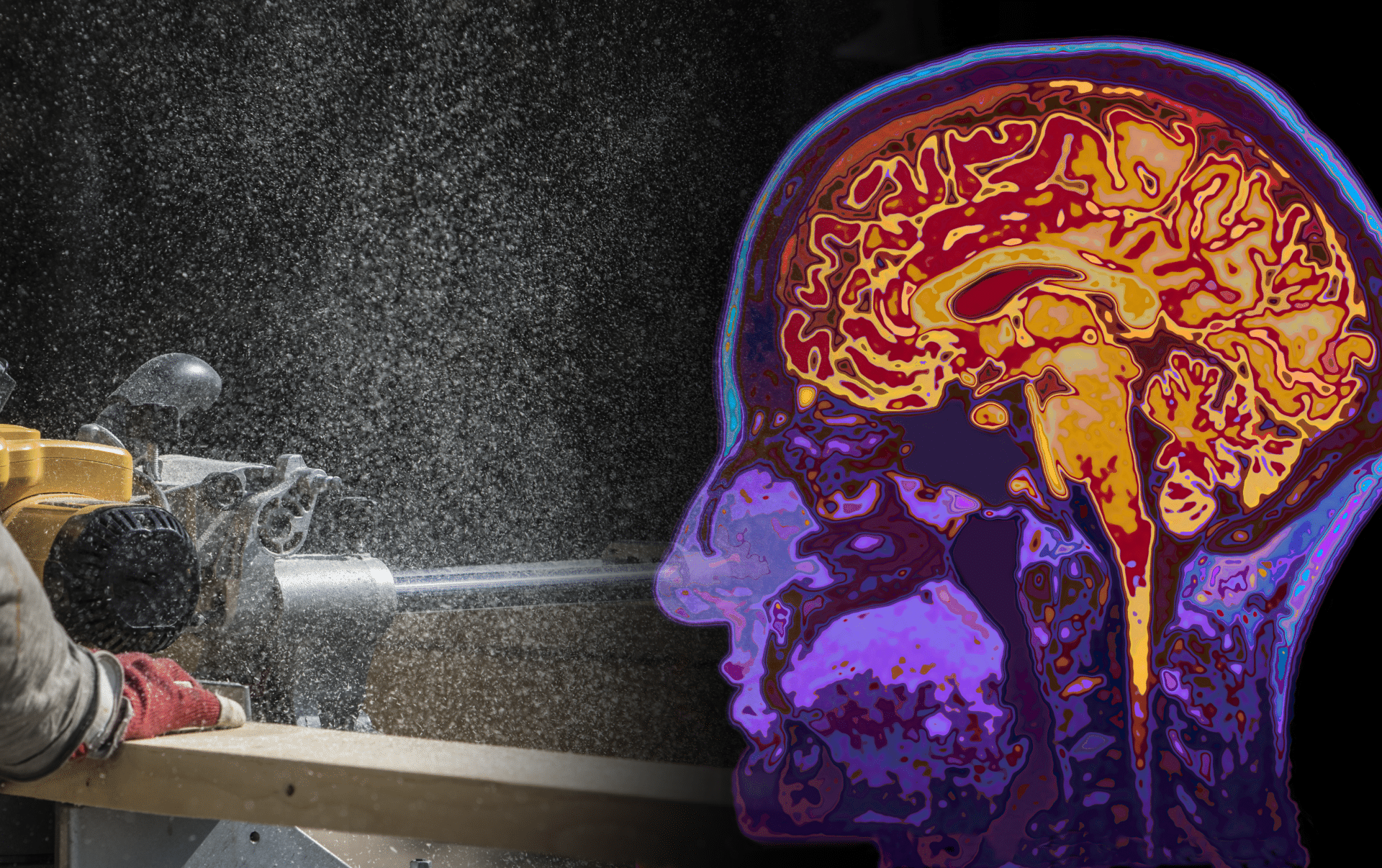

The study, conducted in the USA and first published in the journal Stroke is titled “Long-Term Exposure to Fine Particulate Matter, Residential Proximity to Major Roads and Measures of Brain Structure“.

Examining the brains of more than 900 people over 60 years old, it revealed that long-term exposure to fine dust causes both brain atrophy (brain shrinkage) and leads to an increased risk of stroke and other disease.

Not only is this news alarming for those who live near busy roads, it also draws attention to the added dangers faced by those working in conditions, and with materials, they may have previously thought safe.

For example, welders, who, despite now using supposedly less dangerous materials and working in spaces where local exhaust ventilation (LEV) is employed, seem to be vulnerable to a far wider range of illnesses than previously thought.

As the report highlighted, even limited exposure of fine dust particles can lead to the heightened risk of cerebrovascular disease and cognitive impairment.

Benjamin Howell on the Fabricator.com says, ‘at the nanolevel, invisible to the human eye, the concentration of particulate matter can pose a great risk to welders. Studies show that welding fume particulates are mostly smaller than 0.1 micrometer, which makes nearly all welding fume particles respirable. They can penetrate deep into the alveolate region of the lungs during inhalation and remain firmly fixed there.’

It’s not all bad news though.

By revealing far greater and far wider reaching dangers than previously acknowledged, the new research means the important issue of how best to protect people from damaging dusts is getting the attention it deserves.

The sheer weight of evidence amassing from the likes of The Journal of Cleaner Production, The British Medical Journal, and Harvard is forcing the hand of governments, regulatory bodies and employers. The necessary steps to protect not just their workers, but every one of us exposed to dangerous airborne pollutants, are being considered and taken. This includes controls, sensors and dust detectors, among other things.

What if a threat could be detected before it even became a threat? What if you could be alerted to the presence of even the smallest of damaging airborne dusts before they had the chance to damage health?

Leading H&S expert John Cairns says:

“The best thing is to detect the hazard before you’re exposed to the hazard. Before you’re exposed to the hazard or a high concentration. You can get the hell out of there, or with the way this new technology works you can set off ventilation systems to clear the area.

The whole ethos behind the Health and Safety Executive (HSE) is to reduce the risk to as low as is reasonably practicable. I think the XD ONE Portable Dust Monitor is adding to that – it’s enhancing the safety system.”

Real-time dust monitoring is an effective way at reducing the risk to workers in hazardous working environments. When combined with RPE, PPE and other equipment, the threats from dust and particle inhalation are reduced drastically. This has a big impact on worker health, morale and productivity.

Send us a message today to find out more about our work to help organisations like yours protect your people from the threat of damaging dust particles with sensors, dust detectors and systems tailored to your work environment.

A sign of things to come.

Despite the protests of Johnson and Johnson, who played the indignation card at a “fundamentally flawed trial, grounded in a faulty presentation of the facts.”

The verdict is “[at] odds with decades of independent scientific evaluations confirming Johnson’s Baby Powder is safe, does not contain asbestos and does not cause cancer,” they quibble.

$2.12 billion in damages tells another story.

That’s what a Missouri court ordered Johnson and Johnson pay to women suffering ovarian cancer caused by asbestos in its baby powder and other talc products. Litigation that looks like just the beginning.

Not just for Johnson and Johnson, who now face‘21,800 lawsuits claiming that its talc products cause cancer because of contamination from asbestos, a known carcinogen,’ but also for the many employers the world over who fail to properly protect their workers from preventable disease.

Sarah Jardine, HSE’s chief inspector of construction says: “Around 100 times as many workers die from diseases caused or made worse by their work than are actually killed in construction accidents.”

In the UK alone, 14,000 people a year die prematurely from largely preventable disease caused by the inhalation of respirable dust in the workplace.

Preventable because there’s no excuse for remaining ignorant of the potentially fatal consequences of exposure to dangerous microscopic airborne dust particles.

While lack of awareness has certainly been a problem in the past, now, with plenty of readily available research, public health messaging and examples of high-profile litigation, there’s simply no reason for companies to ignore their responsibilities,

Especially following new advances in dust measurement technology.

So not only is ignorance (still) an illegitimate excuse, with new real-time dust monitoring technology that provides you and your workers with real time and highly accurate dust readings in any working environment, so, too, is blaming a lack of suitable technology.

Put simply, if you’re serious about running a business you need to be serious about protecting people from the dangers of dust inhalation that surround them. Serious about both understanding those dangers and then putting the measures in place to mitigate them.

And as if the moral obligation wasn’t enough, the commercial implications are enormous, too; as Johnson and Johnson are discovering.

There’s more to worry about than the obvious bottom line legal costs and compensation. You need to consider the reputation costs in the form of lost business opportunities and even share price, insurance premium hikes, loss of production or reduced output, sickness cover and pay, and the lack of future legal and financial protections. All the many, undesirable and inevitable consequences of being exposed as negligent. The last thing any business needs or wants.

Are you still unclear about the extensive danger of dust? Or do you already realise the danger, want to do something about it but are unsure how real-time dust monitoring technology can help you?

Either way feel free to get in touch. We’ll tell you the many ways that we help businesses across all sorts of sectors, all over the world. Everything you need to know about protecting your workers from the threat of disease, and your business from the threat of litigation. And all its damaging implications.

As any responsible employer knows – a clear threat to the health and welfare of your staff demands a clear response.

In industries such as construction, mining, tunnelling and manufacturing, the obvious risks to health posed by clouds of workplace dust can be tackled in new and different ways. Some precautions and protections include:

With more awareness of the dangers of dust inhalation, these protections become more effective as they are applied more extensively across different scenarios and environments.

However, dust monitors and other other equipment are only part of the story.

More dangerous than the dust you can see, is the dust you can’t see.

Dust can reach beyond the frontline workers benefiting from protection to threaten support and ancillary staff nearby.

An unfortunate consequence of focusing efforts solely on frontline workers is there are other members of the team who aren’t monitored and protected. Plant and equipment operators working in enclosed cabins, for example, might assume they’re safe but, with microscopic airborne hazards so hard to detect, they’re still exposed to serious amounts of risk.

This is one of the main reasons for the introduction of a new international standard for a consistent approach to designing, testing, operating, and maintaining the air-quality systems of operator enclosures – ISO 23875.

A standard that recognises and responds to the extent of the dangers caused by dust right across a working environment.

It’s a move that’s been welcomed across the board, with the Australian Mining Safety Journal and Mining Review Africa writing, ‘the new standard is likely to place a greater emphasis on the air quality inside the cabin than previously addressed.’

A recent ISO workshop run by Jeff Moredock, Lead at the ISO Working Group, advertised that the new cabin air standard will ‘Improve operator alertness, create a safer work environment and increase productivity.’

Of course, the big question is how do you properly assess the air quality in your cabin? How can you enforce a new and improved standard if you’re not able to accurately record particulate levels in real time?

This makes the introduction of new, wearable or in-cab, real-time dust monitoring technology, such as the XD ONE Portable Dust Monitor, so timely.

The XD ONE is low cost, lightweight, easy to use, easy to maintain and 5 times more accurate than other devices. It continually measures every particle from as small as 0.38 to 40 μm. By issuing every operator an XD ONE, they’re constantly reading the air quality in their immediate environment and instantly alerted to any danger.

In the past, dust monitors were large, clunky pieces of technology that needed to be placed in an area you expected to be hazardous. This was time consuming and took multiple workers to place, set-up and maintain and was inaccurate and often not in real time.

As this equipment has developed, it can now be worn by workers to monitor the dust particles in the space directly around their airways.

The XD ONE Portable Dust Monitor also delivers results in real-time, making it an important part of any safety system or process. Dust can be released at any point and isn’t always noticeable. It can also travel long distances on very slight air currents, so the more warning employees have, the better they can react.

With new regulations pushing for better safety measures and standards in hazardous workplaces and environments, you need to stay on top of everything. Your workers will also benefit, and this keeps them working for longer.

Get in touch today for more details on how the XD ONE Portable Dust Monitor can help you align with ISO Standard 23875 as well as protect workers across your whole site from the danger of microscopic airborne dust.