New test findings released, confirm the efficacy of a world-first real-time monitor for silica dust, which represents a revolution in the protection for workers exposed to respirable crystalline silica (RCS) dust.

As a leading workplace safety technology company, we have developed the AIR XS Silica Monitor, designed to protect workers against lung diseases such as silicosis by providing real-time readings of levels of crystalline silica in the air.

We have recently commissioned a leading occupational hygiene and laboratory testing organisation to conduct independent testing of the AIR XS. The results show the AIR XS repeatedly provided consistent, accurate, real-time data throughout an eight-hour testing period.

The testing demonstrates that AIR XS can improve worker safety by providing instant information to businesses and workers exposed to RCS, instead of having to wait up to four weeks to know their level of exposure to this killer dust, which is the current industry standard.

While the Australian Government recently implemented a ban on engineered stone, commencing 1 July 2024, the process most synonymous with creating silica dust, Group CEO Glyn Pierce-Jones said this ban alone would not solve the current health crisis caused by RCS.

“Silica dust is found in most building materials, so while banning engineered stone is a positive step, it’s not a holistic solution. The real issue facing the industry is the current archaic methods of testing for silica dust and the delay it causes in creating the safest possible workplace.”

The AIR XS is already being used in Australia to monitor RCS levels in many industrial locations.

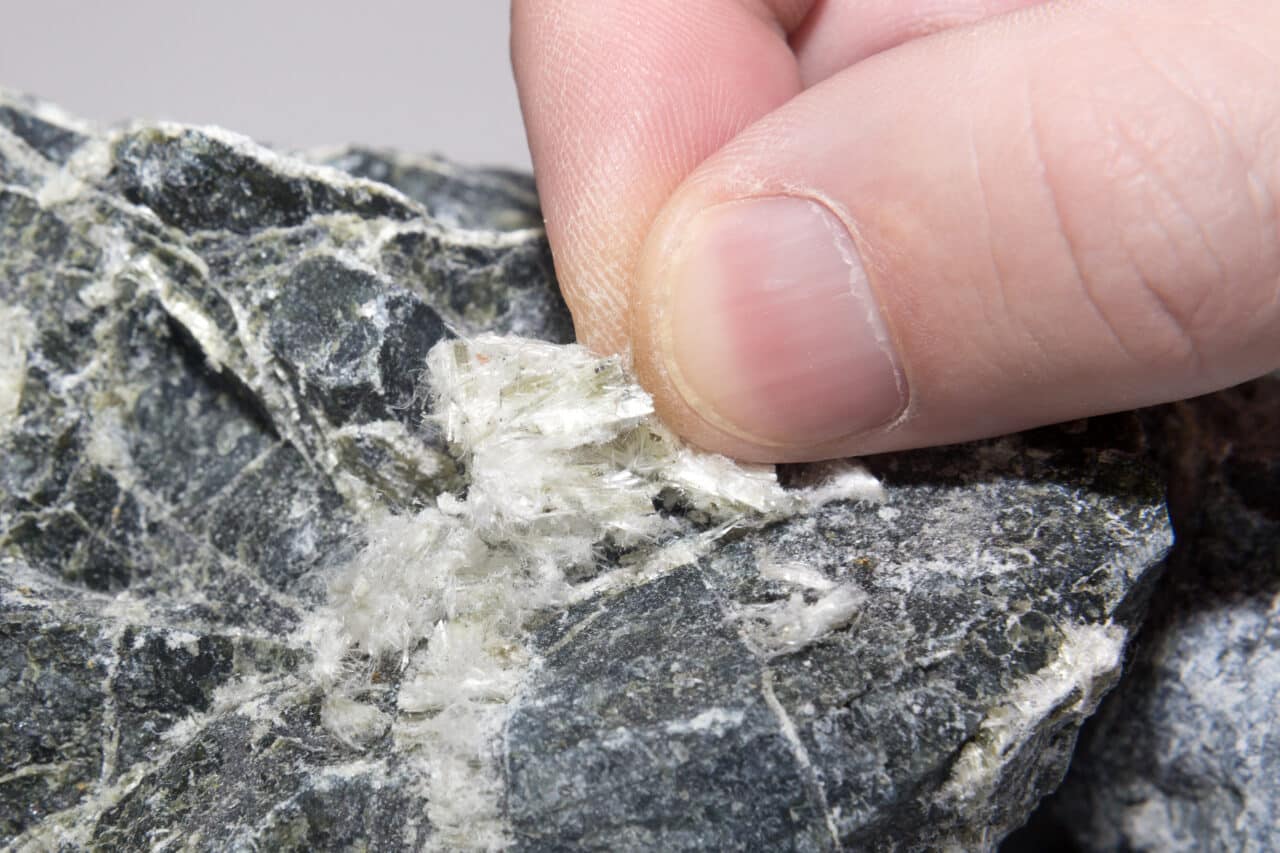

Silica occurs naturally in soil, sand and granite; however, it is almost harmless in that state. Once those materials have been disturbed through construction or mining, silica dust is generated and can be inhaled into the lungs. This dust can cause silicosis, and other types of lung diseases and cancer, which are often irreversible and progressive.

Recent research from The Lung Foundation showed an estimated 600,000 Australian workers and between 40-50 million workers worldwide are exposed to silica dust across a wide range of industries including quarrying, construction, tunnelling, mining and many manufacturing processes.

The current approach to test for RCS is gravimetric sampling, the process requires collection, processing, and laboratory analysis of the sample, which is both time-consuming and costly for businesses. Direct-reading instruments offer businesses the ability to monitor employee safety on sites in real-time, eliminating the delays of weeks typically associated with potential RCS exposure.

Mr Pierce-Jones emphasised the urgent need for enhanced safety measures for anyone who may be in contact with silica.

“The current testing methodology for RCS only allows users to take an average reading over an eight-hour period and typically takes up to four weeks to produce a result,” Mr Pierce-Jones said.

“Our AIR XS Silica Monitor was designed to provide an accurate reading with immediate results, letting workers know when their health is in danger and allowing employers to respond in the most efficient manner.”

“These latest test results are another indicator of what we already knew at Trolex – that the AIR XS could be part of a desperately needed solution to an urgent health crisis.”

Our AIR XS Silica Monitor, an innovative real-time respirable silica (RCS) monitoring device, has been deployed at a major railway operations project to monitor the levels of RCS which workers may be exposed to.

The Central Rail Systems Alliance (CRSA), an alliance between Network Rail, Balfour Beatty, AtkinsRéalis and TSO have been using an AIR XS unit to monitor the levels of RCS released when damaged rail tracks are replaced; when rail track is damaged or needs replacing, the ballast surrounding the track is disturbed and can release RCS. The AIR XS unit was supplied by our UK partners Sunbelt UK & Ireland.

The challenge faced by CRSA was to measure the level of RCS and accompanying dust being released into the atmosphere during the unearthing process of 425m rail and ascertain the level of risk associated for those working in the immediate and surrounding environments. The AIR XS unit was manoeuvred around the site in-line with project progress, so that working scenarios can be accurately represented in the data set.

Upon conclusion of the project, Madeline Dunn, the Health and Safety Advisor for CRSA praised the monitoring and recording capabilities of the AIR XS, saying “We have completed trials prior, however this is the only unit where it is measuring silica and not just general dust levels. We gained the knowledge that the exposure levels were actually higher than we anticipated with even low-level ballast disturbance.”

Thanks to the team at Sunbelt Rentals UK & Ireland for the in-depth case study which you can read in full here.

The UK’s favourite DIY and home improvement expert, Tommy Walsh, is calling for more to be done to protect workers from the dangers of silica dust.

Tommy believes that the issue of air quality on building sites should be a national concern, and that silica dust should be viewed the same way as asbestos.

While he became aware of the dangers of silica dust as an issue around five years ago, in relation to the disposal of plasterboard, Tommy says that he has not heard the issue discussed on building sites. This is in spite of the fact that 81% of those regularly exposed to silica dust are construction workers.

Tommy shared that the majority of health and safety concerns on smaller building sites are focused around obvious, external risks, such as falling from a ladder, electricity and water. As a result, he believes that more needs to be done to raise awareness of “invisible” risks, such as occupational silicosis, which is the most common chronic lung disease in the world.

He continued, “over half of the country’s construction is done by small builders and ‘one-man-band’ outfits. Air quality has always been a secondary concern to them, as they don’t know enough about it. Everyone would rather work safe than not safe, but they can’t do that if they don’t have the awareness. Health and safety can often be ignored due to cost-saving, time-saving, or ignorance, but if we can normalise the importance of air quality it will make it harder to ignore.”

Recent data has shown that respirable crystalline silica (RCS) is the biggest risk to construction workers after asbestos, with cases and exposure rising year on year. There are 12,000 deaths a year in the UK from inhalation of dust including silica in the workplace, opposed to just 142 recorded due to workplace accidents between 2020/2021. What’s more, there are an estimated 50,000 workers worldwide exposed to silica dust.

The scale of the issue is not matched by the awareness and action needed to prevent it.

Silicosis, as well as being the world’s most common occupational lung disease, can increase a person’s risk of tuberculosis, kidney disease, arthritis, and lung cancer. The consequences of occupational silicosis have been estimated to cost employers in the UK construction industry over £1 million per year.

In order to raise awareness and protect construction workers from this entirely preventable disease, we’ve launched the AIR XS Silica Monitor, the world’s first real-time silica monitor, which can provide real-time data of dangerous silica dust particles workers are exposed to across any given day.

Requiring no complicated set-up and only five minutes of maintenance a month, the AIR XS is easy-to-use and provides accurate, real-time RCS monitoring with minimal training, letting workers know if the amount of RCS content in their workspace is increasing as they work and when it has risen to dangerous levels.

Protecting the health and safety of the people who work for you is the ethical thing to do. It also makes good business sense as your people are your greatest asset.

But even if you aren’t driven by a moral or financial imperative, governments around the world are toughening up on the legislation that protects workers, so it’s not something any business can afford to ignore.

While some threats are obvious, others are invisible and incredibly hard to accurately detect, such as the deadly silica dust that are the by-product of many industries and manufacturing processes.

Silica dust is linked with severe health problems. It has been dubbed the ‘new asbestos’ and has already been the subject of litigation. Yet it’s something that has historically been impossible to monitor in real time.

Our Construction Industry Health and Safety Survey Winter 2021 shows that employers are concerned about safety, with nine out of 10 respondents recognising that worker safety is important or very important.

But it also revealed that on the ground it can be hard to meet the health and safety challenge, particularly when it comes to dust monitoring, which for a fifth of respondents accounted for half of their safety budget.

This in-depth report looks at how real-time, wearable dust monitoring technology can help to solve the issues from the findings of the Construction Industry Health and Safety Survey Winter 2021.

The findings ultimately mean that it’s clear we need a new approach to dust monitoring. One that looks to the future and is inspired by the intelligent tech revolutionising every other aspect of our lives.

It’s time to act now to tackle danger of hazardous dusts, like silica dust, by investing in smarter solutions to protect the air we breathe, with real-time dust monitoring.

***

What might seem like a nine-year journey to develop the Trolex AIR XS Silica Monitor actually goes back 150 years. Our new real-time silica detection technology has surprising origins…

It starts at a time when miners had next to no protection, especially from harmful silica dust, and to a place that ‘roofed the world’; Snowdonia’s beautiful, bleak, Blaenau Ffestiniog.

Recently awarded UNESCO heritage status, it was here that my grandfathers, great grandfathers, uncles, and cousins all worked, mining slate.

Arawn and Ieuan. Dai and Dewi. Merfyn and Maldwyn.

And it’s here that many of them died, often as young as in their 40s, from occupational silicosis.

No health and safety. No silica detection and prevention. No chance.

It makes the work we do at Trolex all the more personal and all the more poignant.

And it’s a major part of the reason we’ve worked so hard to solve the age-old problem of occupational silicosis.

So that modern-day miners and quarry workers – in fact, anyone who might come into contact with silica in their working lives, from construction workers to plasterers, factory workers and stonemasons – will never have to suffer the same fate as my forefathers.

And all it took was vision and ingenuity, optimism and grit, and endless trips to the bank manager. And despite being told we’d never do it – we’ve done it.

New real-time dust monitoring technology that offers new hope to people who previously had no hope of avoiding an unnecessary, painful and premature end to their lives caused by occupational lung diseases.

It’s called the AIR XS Silica Monitor.

And it’s astonishing.

The world’s first real-time silica detection technology saving lives all over the world – made of legends.

As they used to say in the back bar at the Miners Inn in Blaenau…

Dyma i chi fechgyn!*

Drop me a line and I’ll tell you everything you need to know about the AIR XS Silica Monitor and the many ways it can benefit your staff and your business.

*Here’s to you, boys!

Silica dust is the new asbestos.

But what if it’s not? What if there’s really nothing new about silica dust in relation to asbestos?

The link between the two is even closer than you may think…

Most people know asbestos as the dangerous insulator used in construction, responsible for over 5,000 related disease-deaths per year, typically lung cancer and asbestosis.

However, in its natural form, asbestos is a naturally occurring fibrous silicate mineral.

Put simply, silicate minerals make up asbestos fibres.

Asbestos is actually just one of the many different forms of silicate materials, in the same way that silica dust is.

The similarities between silica dust and asbestos are much closer than people are aware of.

There is a different attitude towards asbestos compared to silica dust.

The dangers of exposure to asbestos are well documented.

Exposure to asbestos can cause serious lung conditions, including asbestosis and mesothelioma. It is the number 1 cause of recorded work-related deaths in the world.

Most people in the UK are aware of its dangers, particularly as asbestos was banned in 1999 for construction work in the UK.

Yet despite all of this, very few people are aware of how dangerous exposure to silica dust is, despite the fact that asbestos fibres are made up of silicate materials, in the same way silica is.

There are many more dangers relating to silica dust than people may be aware of.

Imagine you are working on refurbishing your bathroom and from the grinding of the ceramic sink and a load of dust becomes airborne.

If you were told that this airborne dust which you were inevitably inhaling was asbestos, you’d probably run a mile, right?

And who could blame you? A dust which is responsible for approximately 90,000 asbestos-related diseases per year. You’d want to get as far away from it as possible.

Well, it’s likely that that dust in your bathroom would in fact be silica dust.

A dust which is made up of silicate materials in the same way asbestos fibres are. A respirable dust which is just as lethal, if not more lethal, in comparison to asbestos dust.

But because it isn’t known to people as being the same as asbestos, the dangers seem to be less of a concern to people.

It’s time to get real and become aware of just how dangerous silica dust is.

It is reported that, in crystalline form, respirable crystalline silica (RCS) is responsible for the death of 600 people per year in Great Britain with 450 of those to workers in construction industry. What’s more, an estimated 50,000 workers are exposed to silica dust globally.

The importance of the dangers of silica dust must be realised, especially with what is known about how dangerous asbestos is.

Asbestos is just as lethal as silica dust. The dangers are the same, yet we cannot afford for the results of exposure to silica dust to be the same as what occurred with asbestos.

Silica could be as lethal as asbestos, if not more so, with equally serious consequences.

Being aware of the issue is the start, action must be taken to protect workers from this dangerous dust.

We cannot afford to let history repeat itself.

Reactec have been specialists in workplace health and safety environments for more than 15 years. Originally focusing on the damaging effects of exposure to vibration, they soon discovered that the most effective way of mitigating workplace risk lies in gathering as much data as possible.

As CEO Jacqui McLaughlin explains, “The traditional approach to health and safety that says ‘I can think about a problem, do a risk assessment and as a consequence of that assessment I can make it safe for people’, we prefer to go one step further and engineer out problems.

If we can measure what’s actually happening in the way of risk, then we can make workplaces a safer place to be.”

Starting with wearable hand/arm vibration monitoring technology to measure vibration exposure, Jacqui and her team quickly realised that the data management, hosting and reporting they provided their clients, was a powerful health and safety tool that could also be usefully applied to other workplace risks.

Rather than try to create new technology to measure a variety of risks, Reactec started to look for partners. Experts in their respective risk fields, whose work could be complemented by their data management technology.

“We see Trolex as a leading expert in how to measure dust and what we’re doing is providing a platform that makes the dust data they collect easy to access and meaningful.

We’re turning their data into meaning.”

“We take the data associated with a process so that your records don’t just look like a bunch of numbers, but they tell you about who was doing what and where. And as you build up more data, you can get more intelligence in terms of process and people and where you need to put in your biggest efforts to get safer environments.”

With new dashboard integration and development soon to be rolled out to a live Trolex XD ONE Portable Dust Monitor client, things are moving fast.

Complementary technology that gives the simple to use and easy to integrate Trolex XD ONE, and Reactec a fast-track route into the world of actionable dust monitoring intelligence.

“And there’s an overlay angle,” says Jacqui.

“With our tech we get information on vibration. We have other tech that gives us information on noise. And if you start overlaying all of that data with dust data and also situational location information, you can create a health risk passport for an individual or a site. It’s the very start of an exciting journey that will provide more and more useful data as clients understand what they can do with the data over time.”

Reactec and Trolex; a marriage made in data and a powerful collaboration that looks set to flourish in the future. Plans are already afoot to take things to the next level with new bluetooth, IoT data recording and cloud-based analytics.

Get in touch today for more information on how you can get the most insightful analysis on your worker health and safety.