‘PM’ or particulate matter, also known as particle pollution is the term for a mixture of solid particles and liquid droplets found in the air.

It’s estimated that air pollution is linked to 43,000 deaths per year in the UK. Worldwide, at least 7 million people die each year from exposure to air pollution, with 91% of the worldwide population living in locations where the air quality exceeded the World Health Organisations (WHO) air pollution guidelines.

These guidelines state that that annual average concentrations of PM2.5 should not exceed 5 µg/m3 and PM10 should not exceed 15 µg/m3 (both for 24-hour periods). According to the WHO, ‘fine particulate matter at PM2.5 can penetrate through the lungs and further enter the body through the blood stream, affecting all major organs’. Exposure to dust at PM2.5 can cause serious disease to the respiratory system, such as lung cancer and COPD, and also can effect cardiovascular diseases, such as a stroke.

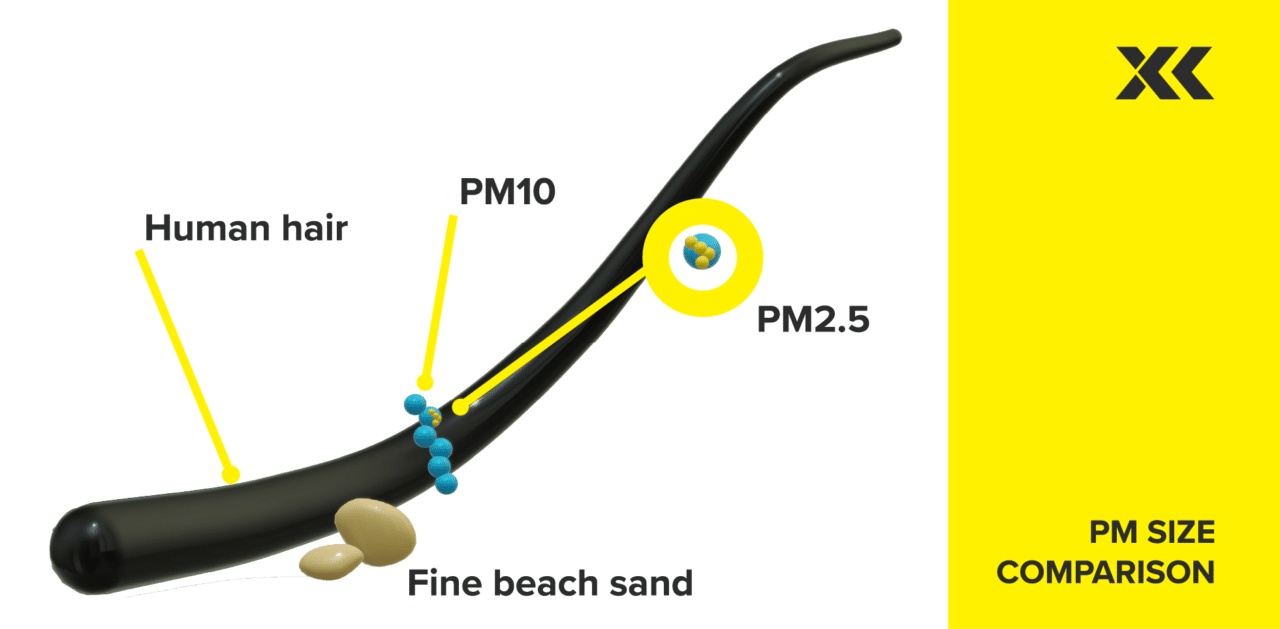

The image below demonstrates PM2.5 and PM10 size in comparison to a single human hair and a grain of sand.

The Department for Environment Food & Rural Affairs (DEFRA), the UK government ministerial department for environment protection, have also highlighted the severity of exposure to air pollution. This growing concern for the UK government estimated in 2010 that the cost of health impacts of air pollution was likely to exceed estimates of £8bn to £20bn.

Although between 2005 and 2022, the UK’s PM2.5 emissions decreased by 41%, emission levels have been relatively steady with small annual fluctuations in the last decade. Industrial combustion is a major source of PM emissions, as well as emissions from industrial production also playing a major part, which can be linked to heavy-dust industry where hazardous particulates can become airborne. Despite some reductions in PM emissions, the threat still very much remains.

A solution to this is real-time dust monitoring. Real-time particulate monitoring allows people in heavy dust loading environments, including industrial applications, to not only understand, but alert them instantaneously when they are exposed to dangerous levels of air pollution. For example, our AIR XD Dust Monitor can alert people in real-time when legislative levels of µg/m3 are breached, over a time-weighted average (TWA) 8-hour period, for both PM2.5 and PM10.

This technology not only offers a simple solution to individuals at high risk of exposure to air pollution by providing instant alerts, but also can help to prevent exposure in the future, as at-risk individuals can learn exactly when and where exposure to air pollution is highest and will likely occur. Thanks to real-time monitoring, both in the UK and Worldwide, we can reduce exposure to air pollution.

The AIR XS Silica Monitor leverages cutting-edge Optical Refraction Technology (ORT) to enhance workplace safety by providing real-time monitoring of respirable crystalline silica (RCS). Unlike traditional particle monitors, AIR XS distinguishes and measures RCS content, enabling immediate detection and response to harmful silica dust levels. This technology is crucial in combating occupational lung diseases such as silicosis, which affects millions of workers globally.

Current monitoring methods, like gravimetric sampling, are time-consuming and often deliver results too late to prevent exposure. In contrast, real-time silica monitoring offers immediate data, significantly reducing the risk of occupational silicosis by enabling prompt action to mitigate hazardous conditions. The importance of such real-time data is highlighted by cases like Joanna McNeill’s, who developed silicosis at the age of just 36. Her story, like many others underscores the necessity for continuous monitoring to protect workers from the threat of silicosis, regardless of their occupational environment.

Our real-time RCS monitor, AIR XS provides a real-time solution to this threat. Workers are not only alarmed and alerted when silica levels exceed legislative limits but can work to best practices by implementing AIR XS with the Hierarchy of Controls, supporting proactive measures to eliminate or minimise exposure to RCS. This move to real-time monitoring as a solution to the threat of silicosis has also been noticed by governing bodies, like the All-Party Parliamentary Group on Respiratory Health.

To learn more about how this real-time solution not only enhances worker safety but also streamlines business operations, click the link below to read the case study in full.

It’s estimated that over 40 million people worldwide are exposed to silica dust in the workplace. Respirable crystalline silica (RCS) contributes to one of the leading causes of death in the workplace, alongside other lung related illnesses. Due to this some of the industry’s most influential countries worldwide are making significant changes to regulations regarding silica exposure in the workplace.

In December 2023, Australia became the first country in the world to ban engineered stone due to rising cases of silicosis. From 1st July 2024, all use of engineered stone in Australia will be prohibited to protect workers from exposure to RCS in the workplace. Engineered stone is a manufactured material made from combining quartz or granite aggregates with resins and pigment and is a common material used in stone bench tops, often found in kitchens and bathrooms. It’s production often results in airborne RCS, leading to significant health risks to those working with it.

With reports that over half a million Australians are exposed to fine silica dust through stonemasonry and construction, figures suggest 103,000 of these workers are likely to be diagnosed with silicosis. The production and manufacturing of stone bench tops is a significant contributor to these statistics. The ban on engineered stone across the entirety of Australia is a step in the right direction to reduce the number of workers exposed to RCS and silicosis diagnosis in the future.

This ruling in Australia looks to have a set a precedent in influencing other countries to do the same. In May 2024, the first cases of silicosis linked to artificial stone countertops in the UK were reported, leading to calls for the material to be banned.

An estimated 600,000 workers are exposed to silica in the UK each year, and in Europe as a whole, 81% of those exposed are employed in construction or in manufacturing products used in the industry. After Australia became the first country worldwide to ban engineered stone in December 2023, UK kitchen company Herringbone announced they would also ban the sale of high-silica quartz worktop due to the risks posed to stonemasons.

Since speaking with their stonemasons about the risk of high quartz in engineered stone, Herringbone made the decision to become the first company in the UK to phase out the sale and production of engineered stone, as well as creating a petition to have the product completely banned in the UK, like in Australia.

In the US, the Biden administration has agreed to limit workers exposure to silica dust in mining, particularly when drilling for coal, ore and completing other mining operations. In April 2024, a ruling was announced to reduce the allowable silica dust levels in mining operations to 50 micrograms per cubic meter, with an action level at 25 micrograms, for an eight-hour workday.

The ruling will also update any respiratory protection standards for mining workers and in addition to silica dust, will also apply to diesel particulate matter and asbestos. The hope is that this will begin to reduce an estimated 1,067 deaths and 3,746 silica related illnesses in mining industries in the US and begin to make mining safer from the risk of RCS for the 55,000 American coal miners across the nation. The rule will come into action one year after its publication in April 2024.

With significant action being taken across major industries worldwide as of mid-2024 and onwards, protection for workers against respirable crystalline silica is becoming more of a high priority in workplaces. With banning of products known to produce dangerous levels of RCS, and with rule changes to limit exposure, workers short- and long-term lung health is becoming better protected than ever.

In an ideal world, the risk of dangerous airborne particles simply wouldn’t exist in the workplace. We cannot understate how important respiratory protective equipment (RPE) is, even compared to all the other safety technologies available.

The proper application of the Hierarchy of Controls (HoC), though Elimination, Substitution, Engineering, Administration and personal protective equipment (PPE) would mitigate the threat and make sure that everyone was properly protected.

The unfortunate reality is that many workers still face threats from a wide range of hazardous dust and particulates, such as silica, construction dust, fibreglass, wood, asbestos and many more. Respiratory protective equipment is one of the most effective safety technologies against silica dust and other harmful inhalants.

While every stage of the HoC can play an important role in helping to make workplaces safer, it’s the final stage, the PPE/RPE – the provision and proper wearing of suitably selected and fit tested RPE – that presents the biggest challenge.

Why?

Because too often, RPE fails to provide the protection that providers or wearers think it does.

The IPPI test is a good way to make sure the RPE and PPE you provide – or have been provided – is fit for purpose. Before entering any environment where there’s a risk of harmful dust inhalation, it’s important to check whether the RPE is:

The Construction Dust Partnership (an industry collaboration that helps help construction industry contractors, employers, operatives and others manage the risk of exposure to dusts and raise awareness) says, ‘any gaps around the RPE’s edges allow the contaminant-laden air to pass straight to the nose/mouth and be inhaled into the lungs.’

For example, did you know that beards or stubble can severely impact the performance of RPE?

‘If the wearer has stubble where the RPE seals to the face, this will make an adequate seal between the skin and the RPE impossible. A lack of knowledge or understanding on how to wear RPE correctly can often lead to an unrealistic expectation of protection.’

In other words, people are working with a false sense of security. Not only must the RPE be fit for purpose, but proper training and guidance must be provided on its use – like any other piece of health and safety technology or equipment. Better would be for checks to be made before entering areas with hazardous substances.

There’s nothing more dangerous than thinking you’re safe when in reality you’re not. When you’re labouring under the illusion that your RPE is protecting you from harm and all it’s doing is placing you squarely in harm’s way, it’s a big problem.

“People are not so good at assessing exposure to a risk,” says risk perception expert Ann Bostrom, of University of Washington.

It’s something we’ve seen clearly during the Covid pandemic. Masks acting as signifiers of safety rather than providing genuine protection.

A dangerous combination of availability and confirmation bias, the psychology is explained in this Forbes article, drawing comparisons between respiratory protective equipment and seatbelts. It cites a report that shows people drive faster and more recklessly when they wear seatbelts. The same applies to cyclists riding less cautiously when wearing helmets.

So what’s the answer? If industry is consistently failing to apply the Hierarchy of Controls well enough to protect workers, or even worse, lulling workers into a dangerously false sense of security, what can businesses do to properly protect their people?

The answer is surprisingly simple.

Real-time dust monitoring that gives you an accurate, realtime understanding of the dust threat you and your workers face.

Properly detecting previously unseen and undetectable threats – seeing it as a real danger, not abstract – allows you to properly challenge it. And in the process, your RPE reclaims its proper protective value – a specific, contextual and essential value.

To be clear, dust monitoring is not a reason to not wear RPE and PPE, but it can make sure you’re aware when the environment changes and whether your equipment is appropriate for the situation you find yourself in.

Instead of being taken for granted, worn out of habit, ‘just in case’ or ‘because that’s the way we do it,’ RPE transforms from dangerous IPPI to safe APPW.

Instead of IPPI equipment, APPW is respiratory protective equipment that’s:

Get in touch today to find out more about how our new AIR XD Dust Monitor, XD ONE Portable Dust Monitor, XD1+ Personal Dust Monitor and AIR XS Silica Monitor – accurate, simple to use, easy to maintain, real-time particulate detection technology – helps your teams use their RPE more effectively.

The IOSH Construction Group Committee Construction Dust Survey makes for sobering reading. Firstly, it highlights the fact that much more needs to be done to increase awareness of the dangers of dust from an employees perspective:

“Dust causes a lower level of concern among employees than the more immediately noticeable dangers of construction, such as falls…they do not perceive it as a significant immediate risk to their wellbeing unlike falls from height, equipment etc.”

It also highlights a lack of awareness from the industry as a whole. Of 618 health and safety professional respondents, ‘44.6 percent thought that the industry gave little or no priority to the issue, and a similar proportion (42.4 percent) felt that it received the same priority as other health issues.’

And even when awareness exists, the report found that compliance is weak.

‘54.0 percent of respondents indicated that workers sometimes fail to follow prescribed methods of work. Over a third of respondents (36.2 percent) indicated that this happened most or all of the time.’

So what’s going on? Why, even when employers and their onsite teams are in possession of the facts, do they too often choose to ignore the dangers posed by dust?

Dangers that lead to 10 deaths a week from lung cancer caused by silica dust, let alone the other illness and premature death from other cancers, silicosis, asthma and chronic obstructive pulmonary disorder (COPD).

You’ll be familiar with the concept of cognitive dissonance, ‘the state of discomfort felt when two or more modes of thought contradict each other’.

Like knowing smoking is bad for you, but continuing to smoke.

Like, “we know dust is dangerous but there’s no convenient, low-cost alternative to handling the risk. So we’ll stick with what we’ve always done.”

Barriers to change

There’s a lot to learn in the Construction Dust Survey.

More than anything, it’s highlighted that despite being increasingly aware of the dangers, people aren’t taking action.

Somehow, industry has convinced itself that the culture and adoption of, the management of, and the cost, complication and general hassle of creating a safe working environment is more trouble than just leaving things be.

Here are just some of the barriers to change noted in the survey:

Culture: The culture of the industry, and its ‘traditional’ view of dust as an expected or normal part of construction work, can be a significant barrier.

Use: Workers often view the controls as cumbersome, impractical, affected by poor maintenance or giving rise to other risks. This deters use.

Employees: Implementing controls effectively depends on good management and supervision. Operators generally choose not to use controls.

Management arrangements: In general, the industry does not seem to manage dust control issues adequately. Comments refer to a link between the management priority given to this issue and the corresponding conditions found on-site.

Cost: Dust control is often viewed as labour-intensive, expensive, time-consuming and a nuisance that slows work.

‘The industry creates this risk. It now needs to acknowledge it, own it and deal with it.’

It somehow seems that as awareness increases, industry seems to think a cultural shift towards safer working environments will run its own natural course over time.

“It is like wearing a hi-vis 15 years ago or hard hats. It took years for the culture to change.” says a contributor to the report.

Fortunately, we’ve taken a far more proactive approach.

What if we could fast track that safer working environment?

What if that cognitive dissonance could be eased instantly and increased awareness could be achieved overnight? And what if you only ever had to use dust control methods when you actually needed them?

It’s hard to not be aware of something when an alarm is screaming in your ears and bright lights are flashing.

Well, here’s the thing.

A low-cost, simple-to-use, personal alarm would help solve the problem overnight.

All those adoption and implementation objections, all the excuses and all those barriers to change would evaporate. Instantly.

And here’s another thing.

That low-cost, simple-to-use, personal alarm exists.

It’s new and it’s here.

The XD ONE Portable Dust Monitor.

Get in touch today and we’ll tell you everything you need to know about how real-time dust and silica monitoring technology can protect your workers from the threat of preventable disease.