Leading medical staff in the UK, writing for medical journal ‘Thorax’, are calling for industries and governing bodies to follow Australia’s new legislation and ban the use of engineered stone, commonly used for kitchen worktops.

It comes after cases of silicosis linked to engineered stone exposure recently came to light globally. Workers who have been exposed to engineered stone quartz and dust are now being affected by and diagnosed with severe lung problems, linked to inhaling such dust. Earlier in the year, it had prompted the Australian government to act and ban the use, manufacturing, and production of engineered stone across the entire country.

Now the UK is being urged to do the same, with the first cases of silicosis related to engineered stone production have now been reported in the country. Various medical staff who have treated workers diagnosed with these cases of silicosis are calling for similar action to be taken in the UK as in Australia.

According to British newspaper i the first 8 cases of silicosis linked to engineered stone use have been confirmed, all of which are men. The average age of all 8 men is 34, with the youngest to be diagnosed just 27 years old. Of the 8 cases, 1 man has died, and 2 others have been referred for lung transplant assessments.

The article from i features an interview with one of the diagnosed workers, Malik al-Khalil, a stonemason who is just 31. After working with engineered stone for 5 years, Malik was diagnosis with silicosis, contracted after cutting engineered stone slabs in a small London workshop. Malik said, “I want to let all the people working in this work know what’s happening from this material” and believes the only solution to this growing problem is a nationwide ban of the product; “Of course [it should be banned] because the silicosis is coming from this material.”

It’s not just Malik and fellow diagnoses patients who are calling for engineered stone to be banned in the UK. Dr Johanna Feary, a respiratory consultant from the Royal Brompton Hospital where Malik al-Khalil is being treated, and lead author for ‘Thorax’, has also highlighted her concerns over exposed to the product. Dr Feary told i “We’ve been anticipating that we would start seeing cases in the UK at some point. That moment has arrived now.”

The team of doctors writing in ‘Thorax’, who highlighted the first 8 cases, have also called for a legal requirement to report cases of silicosis, as well as calling for the implementation of health and safety regulation for both small companies and national guidelines to treat and monitor for silicosis.

You can read the full article from i newspaper here.

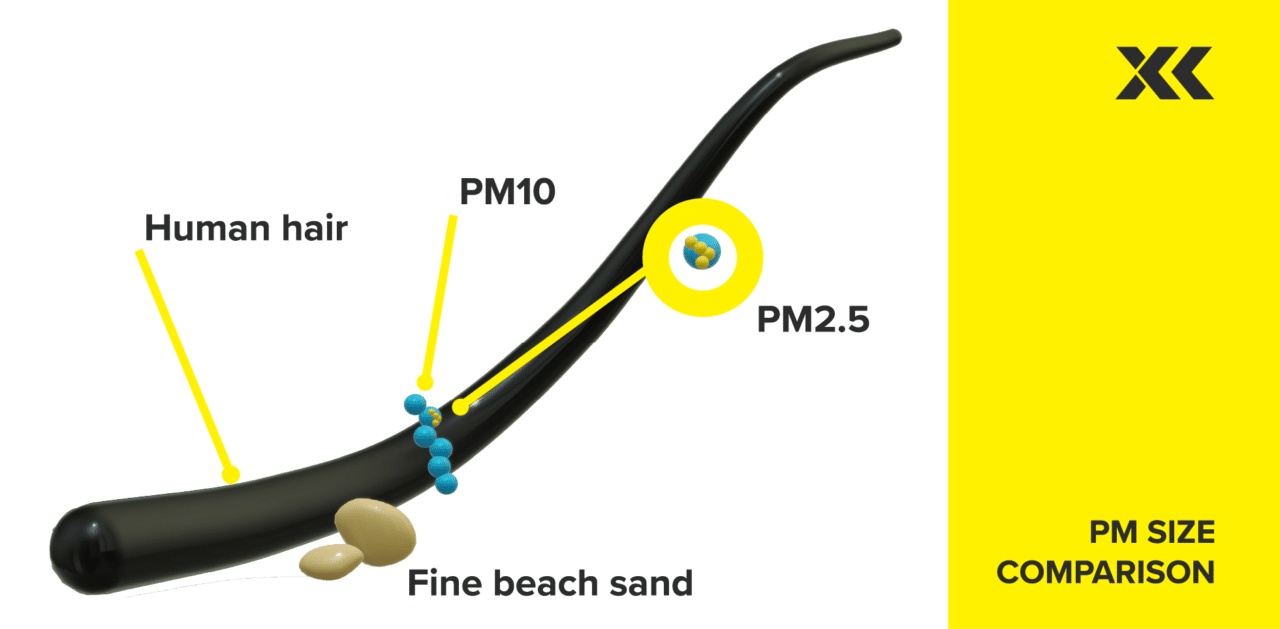

‘PM’ or particulate matter, also known as particle pollution is the term for a mixture of solid particles and liquid droplets found in the air.

It’s estimated that air pollution is linked to 43,000 deaths per year in the UK. Worldwide, at least 7 million people die each year from exposure to air pollution, with 91% of the worldwide population living in locations where the air quality exceeded the World Health Organisations (WHO) air pollution guidelines.

These guidelines state that that annual average concentrations of PM2.5 should not exceed 5 µg/m3 and PM10 should not exceed 15 µg/m3 (both for 24-hour periods). According to the WHO, ‘fine particulate matter at PM2.5 can penetrate through the lungs and further enter the body through the blood stream, affecting all major organs’. Exposure to dust at PM2.5 can cause serious disease to the respiratory system, such as lung cancer and COPD, and also can effect cardiovascular diseases, such as a stroke.

The image below demonstrates PM2.5 and PM10 size in comparison to a single human hair and a grain of sand.

The Department for Environment Food & Rural Affairs (DEFRA), the UK government ministerial department for environment protection, have also highlighted the severity of exposure to air pollution. This growing concern for the UK government estimated in 2010 that the cost of health impacts of air pollution was likely to exceed estimates of £8bn to £20bn.

Although between 2005 and 2022, the UK’s PM2.5 emissions decreased by 41%, emission levels have been relatively steady with small annual fluctuations in the last decade. Industrial combustion is a major source of PM emissions, as well as emissions from industrial production also playing a major part, which can be linked to heavy-dust industry where hazardous particulates can become airborne. Despite some reductions in PM emissions, the threat still very much remains.

A solution to this is real-time dust monitoring. Real-time particulate monitoring allows people in heavy dust loading environments, including industrial applications, to not only understand, but alert them instantaneously when they are exposed to dangerous levels of air pollution. For example, our AIR XD Dust Monitor can alert people in real-time when legislative levels of µg/m3 are breached, over a time-weighted average (TWA) 8-hour period, for both PM2.5 and PM10.

This technology not only offers a simple solution to individuals at high risk of exposure to air pollution by providing instant alerts, but also can help to prevent exposure in the future, as at-risk individuals can learn exactly when and where exposure to air pollution is highest and will likely occur. Thanks to real-time monitoring, both in the UK and Worldwide, we can reduce exposure to air pollution.

It’s estimated that over 40 million people worldwide are exposed to silica dust in the workplace. Respirable crystalline silica (RCS) contributes to one of the leading causes of death in the workplace, alongside other lung related illnesses. Due to this some of the industry’s most influential countries worldwide are making significant changes to regulations regarding silica exposure in the workplace.

In December 2023, Australia became the first country in the world to ban engineered stone due to rising cases of silicosis. From 1st July 2024, all use of engineered stone in Australia will be prohibited to protect workers from exposure to RCS in the workplace. Engineered stone is a manufactured material made from combining quartz or granite aggregates with resins and pigment and is a common material used in stone bench tops, often found in kitchens and bathrooms. It’s production often results in airborne RCS, leading to significant health risks to those working with it.

With reports that over half a million Australians are exposed to fine silica dust through stonemasonry and construction, figures suggest 103,000 of these workers are likely to be diagnosed with silicosis. The production and manufacturing of stone bench tops is a significant contributor to these statistics. The ban on engineered stone across the entirety of Australia is a step in the right direction to reduce the number of workers exposed to RCS and silicosis diagnosis in the future.

This ruling in Australia looks to have a set a precedent in influencing other countries to do the same. In May 2024, the first cases of silicosis linked to artificial stone countertops in the UK were reported, leading to calls for the material to be banned.

An estimated 600,000 workers are exposed to silica in the UK each year, and in Europe as a whole, 81% of those exposed are employed in construction or in manufacturing products used in the industry. After Australia became the first country worldwide to ban engineered stone in December 2023, UK kitchen company Herringbone announced they would also ban the sale of high-silica quartz worktop due to the risks posed to stonemasons.

Since speaking with their stonemasons about the risk of high quartz in engineered stone, Herringbone made the decision to become the first company in the UK to phase out the sale and production of engineered stone, as well as creating a petition to have the product completely banned in the UK, like in Australia.

In the US, the Biden administration has agreed to limit workers exposure to silica dust in mining, particularly when drilling for coal, ore and completing other mining operations. In April 2024, a ruling was announced to reduce the allowable silica dust levels in mining operations to 50 micrograms per cubic meter, with an action level at 25 micrograms, for an eight-hour workday.

The ruling will also update any respiratory protection standards for mining workers and in addition to silica dust, will also apply to diesel particulate matter and asbestos. The hope is that this will begin to reduce an estimated 1,067 deaths and 3,746 silica related illnesses in mining industries in the US and begin to make mining safer from the risk of RCS for the 55,000 American coal miners across the nation. The rule will come into action one year after its publication in April 2024.

With significant action being taken across major industries worldwide as of mid-2024 and onwards, protection for workers against respirable crystalline silica is becoming more of a high priority in workplaces. With banning of products known to produce dangerous levels of RCS, and with rule changes to limit exposure, workers short- and long-term lung health is becoming better protected than ever.

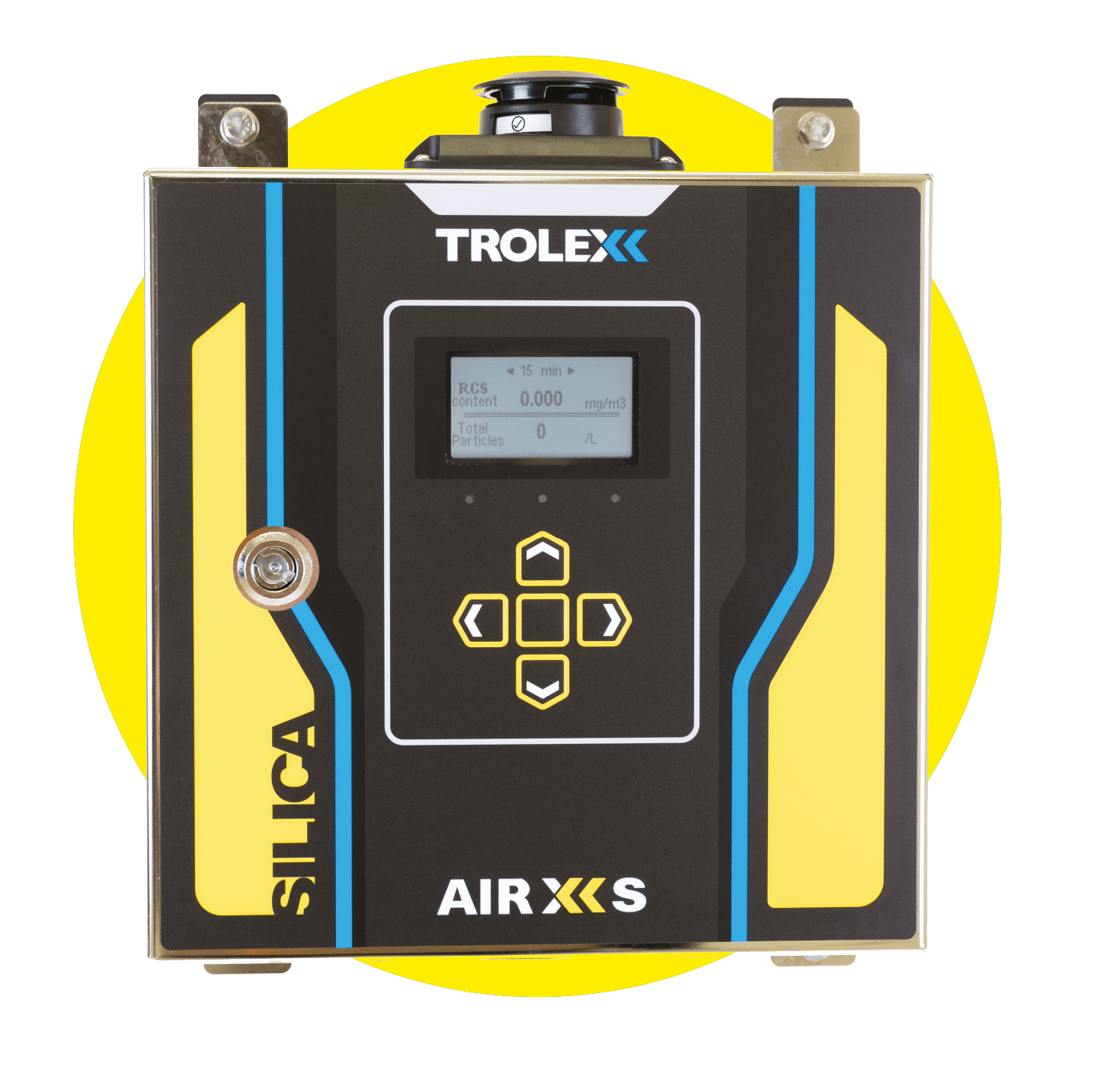

Launched in 2022, the AIR XS Silica Monitor isn’t like other silica monitors on the market. If you’ve been in the Health and Safety space, it’s likely you’ll know about Optical Particle Counter (OPC), also known as “light-scattering”; but our patented AIR XS isn’t just another OPC.

Unlike traditional Optical Particle Counters (OPCs) that rely on light scattering and interruptions to deduce particle size and quantity, the patented Optical Refraction Technology (ORT) used in the AIR XS shines a laser through each particle, capturing its refraction on multiple sensors.

In our blog below, we reference Pink Floyd’s 1973 album Dark Side of the Moon to explain one way to how ORT works. It’s not exact by any means but the refraction of the light coming out of the prism shows an example of how light refracts, similar to a crystalline particle.

In 2020, the All-Party Parliamentary Group for Respiratory Health (APPG) issued the report “Silica, the next asbestos?”, which examined the disproportionate effect of silica dust to construction workers’ lives.

Since the publication of that report, the APPG were contacted by a number of experts on the subject matter, who highlighted the advances in risk reduction and the particularly promising rise of real-time dust and silica monitoring technology.

“Trolex believe that the most obvious and immediate benefit of real-time monitoring is in improving safety for those potentially exposed to silica in the workplace.”

The new, revised report, titled “Improving Silicosis Outcomes in the UK” also explored these new silicosis prevention strategies, including some input from Trolex on the subject matter. From this, the APPG raised several clinical and regulatory recommendations to protect workers from the dangers of occupational silicosis going forward.

“We recommend that the Health and Safety Executive (HSE) assesses and determines the data and technology needed to allow the UK to reduce the WEL for work with silica to 0.05mg/m3.”

The recommendations from the APPG’s report indicate a number of changes need to be made in order to improve safety across all UK industries which use silica. These recommendations focus on both ways to prevent exposure to dangerous respirable crystalline silica (RCS) in the workplace, including improvements in education, real-time monitoring and reducing exposure limits, as well as improving health and support for those who currently suffer with silicosis.

“We recommend that the HSE actively considers and consults with industry on the positions of real-time monitoring to complement the hierarchy of controls.”

The effects of silicosis in the stone industry is not an unknown issue.

But to what extent are stone workers aware of this issue? Are the specific causes of silicosis in the stone industry common knowledge?

A scientific report from nature.com highlights the difference between engineered stone and natural stone, in relation to their silica content, shedding some light on where the cause of silicosis could lie in the stone industry.

Silicosis is one of the most dangerous respirable lung diseases in the workplace, especially when exposure to harmful silica dust is a common occurrence, such as in the stone industry.

It is estimated that globally, 40 to 50 million workers are exposed to silica dust in the workplace.

The Natural Stone Institute guide to awareness and prevention of silicosis determines that exposure to respirable crystalline silica (RCS), specifically in the stone industry comes from cutting or grinding materials, most commonly which contain quartz, is composed of silica dust.

The purpose of the study from nature.com was to see, in relation to RCS, what the most threatening scenario was for worker’s health, in real time, when working with different compositions of stone.

In the study, 12 engineered stones were assessed against three natural stones – white marble, white granites and black granites. By dry-cutting all stones, silica dust was captured in a closed environment and subjected to various assays to determine both chemical and physical properties.

The 12 engineered stones’ silica content varied from one another, and the total RCS content made up of quartz and cristobalite ranged from 70.4% to 90.9%. By comparison, the natural stone’s silica content ranged from 3.5% to 30.1%, marking a clear difference.

As well as this, the dry-cutting of engineered stone generated finer RCS particles with one engineered stone having an average size of as little as 190 nanometres, meaning it could reach deeper in the lungs, in turn causing more damage. Contrastingly, the smallest average particle size of the natural stone was black granite, with an average size of 503 nanometres.

The results of this study concluded that silica dust emissions from engineered stones had a much higher concentration of quartz and cristobalite, therefore having a higher silica content and subsequently more damaging impact on respiratory health.

Ultimately, the report concluded that the higher the silica content of the stone, as well as the smaller size of RCS particles, the more dangerous it is to respirable health.

The Natural Stone Institute conclude in their guide to occupational silicosis that there is no cure for silicosis; however, “with the proper equipment, training, vigilance and continual monitoring, you and your shop floor can be free of the dangers”.

Being aware that harmful silica dust is higher within engineered stone, compared to natural stone, and by monitoring for this, as well as using correct respirable protective equipment (RPE) when working with engineered stone, it allows for correct precautions to be taken to avoid silicosis.

We’ve developed the world’s first real-time silica monitor, the AIR XS Silica Monitor, and, along with other health and safety controls, this is one of the tools that will help to prevent occupational silicosis for those exposed to harmful silica dust in the workplace.

The UK’s favourite DIY and home improvement expert, Tommy Walsh, is calling for more to be done to protect workers from the dangers of silica dust.

Tommy believes that the issue of air quality on building sites should be a national concern, and that silica dust should be viewed the same way as asbestos.

While he became aware of the dangers of silica dust as an issue around five years ago, in relation to the disposal of plasterboard, Tommy says that he has not heard the issue discussed on building sites. This is in spite of the fact that 81% of those regularly exposed to silica dust are construction workers.

Tommy shared that the majority of health and safety concerns on smaller building sites are focused around obvious, external risks, such as falling from a ladder, electricity and water. As a result, he believes that more needs to be done to raise awareness of “invisible” risks, such as occupational silicosis, which is the most common chronic lung disease in the world.

He continued, “over half of the country’s construction is done by small builders and ‘one-man-band’ outfits. Air quality has always been a secondary concern to them, as they don’t know enough about it. Everyone would rather work safe than not safe, but they can’t do that if they don’t have the awareness. Health and safety can often be ignored due to cost-saving, time-saving, or ignorance, but if we can normalise the importance of air quality it will make it harder to ignore.”

Recent data has shown that respirable crystalline silica (RCS) is the biggest risk to construction workers after asbestos, with cases and exposure rising year on year. There are 12,000 deaths a year in the UK from inhalation of dust including silica in the workplace, opposed to just 142 recorded due to workplace accidents between 2020/2021. What’s more, there are an estimated 50,000 workers worldwide exposed to silica dust.

The scale of the issue is not matched by the awareness and action needed to prevent it.

Silicosis, as well as being the world’s most common occupational lung disease, can increase a person’s risk of tuberculosis, kidney disease, arthritis, and lung cancer. The consequences of occupational silicosis have been estimated to cost employers in the UK construction industry over £1 million per year.

In order to raise awareness and protect construction workers from this entirely preventable disease, we’ve launched the AIR XS Silica Monitor, the world’s first real-time silica monitor, which can provide real-time data of dangerous silica dust particles workers are exposed to across any given day.

Requiring no complicated set-up and only five minutes of maintenance a month, the AIR XS is easy-to-use and provides accurate, real-time RCS monitoring with minimal training, letting workers know if the amount of RCS content in their workspace is increasing as they work and when it has risen to dangerous levels.

You may have seen The All Party Parliamentary Group (APPG) for Respiratory Health report ‘Silica – the next asbestos’ released in March 2020?

In it, it states:

“Construction workers are still 100 times more likely to die from a preventable occupational disease than from an accident. We also know that approximately 12,000 deaths in the industry each year are linked to exposure to dust and chemicals.”

“Figures from IOSH show that roughly half a million people are exposed to RCS at work in the UK. They estimate that in Europe as a whole, 81% of these are employed in construction or in manufacturing products used in that industry.”

Experts at Trolex brought our new technology to the APPG’s attention and explained our nine-year silica detection R&D project that resulted in development of the new real-time silica monitor – work that we’d kept closely under wraps until mid 2021.

The original report refers to Workplace Exposure Limits (WELs) of dust. It says:

“Dust monitoring is vital. Technology advances mean that new methods of real-time exposure level monitoring are now possible. Knowing what the actual exposure levels are is important as exposure will depend on the actual task (e.g. cutting concrete is higher risk than breaking concrete, and the actual exposures depend on the concrete mixture).

“The new Code of Practice for Tunnelling […] that requires the use of new technology which is just becoming available and gives an instantaneous measurement.”

The instantaneous measurement the report refers to is the measurement of a variety of dust and particulates (something we already do with our AIR XD Dust Monitor and XD One Portable Dust Monitor, XD1+ Personal Dust Monitor products) – not specifically silica. Silica always being too difficult to uniquely identify.

Until now.

Our new silica-specific monitoring technology is a game changer.

By working with the authors of the APPG to share the features, benefits and thinking behind the new real-time silica monitoring technology they’ve been able to update the report with new advice on how to best protect workers from the dangers of respirable crystalline silica (RCS).

The world’s first real-time silica monitor, the Trolex AIR XS Silica Monitor has been determined as ‘Highly Commended’ by the British Safety Industry Federation (BSiF) at their 2022 awards ceremony.

With rising cases of occupational silicosis caused by the inhalation of silica dust, AIR XS was recognised in the ‘Product Innovation’ category, for its improvement towards detecting respirable crystalline silica (RCS), as a truly innovative product.

The BSiF Awards, in association with the Safety and Health Excellence Awards, took place on Wednesday 6 April 2022 at The Vox, NEC, Birmingham.

Hosted by renowned actor and comedian Hugh Dennis, the awards recognised some of the most prestigious and respected companies within the health and safety industry across Britain.

Three awards were presented by the BSiF to companies who are excelling in the health and safety industry; these awards were the Customer Services Awards, the Safety Solution Award and the Product Innovation Award, the latter of which the AIR XS had entered.

The ‘Product Innovation’ category focuses on products that make a difference, and find new solutions to improving health and safety across a variety of industries and environments in Britain.

Focusing on new and innovative technology used in developing these nominated products, this category was an opportunity for us to highlight the effect which real-time silica monitoring will have on improving health and safety in specific markets.

Therefore, not only did being the world’s first real-time silica dust monitor on the market help us receive ‘Highly Commended’ recognition, but also the innovation and development of the product itself.

Using optical refraction technology developed in-house by our engineering team and produced with the support of the Centre for Work Health and Safety, the AIR XS demonstrated the effort put in and the belief everyone connected to this product has on its potential.

Our Managing Director, Steve Holland, claimed, “it was a privilege to stand up on behalf of Trolex at such an important event and this award is absolutely deserving to everyone here.” This award has highlighted the amount of work gone into this innovative product and the potential it has on the industry as a whole.

“There is still lots of work ahead, but this undoubtedly begins a new era of growth, opportunity and excitement for the business” added Steve.

The results of the BSiF Awards come at an exciting time, as Trolex were also announced as a finalist of the Better Society Awards for the AIR XS, in the ‘Tech for Good’ category, just weeks after winning the ‘Best Technology Award’ at The International Surface Event.

Real-time silica monitoring technology has the potential to save protect workers from high exposure to respirable crystalline silica has the potential to save millions of lives.

Get in touch with one of our experts today to learn more about the AIR XS Silica Monitor.

***

What might seem like a nine-year journey to develop the Trolex AIR XS Silica Monitor actually goes back 150 years. Our new real-time silica detection technology has surprising origins…

It starts at a time when miners had next to no protection, especially from harmful silica dust, and to a place that ‘roofed the world’; Snowdonia’s beautiful, bleak, Blaenau Ffestiniog.

Recently awarded UNESCO heritage status, it was here that my grandfathers, great grandfathers, uncles, and cousins all worked, mining slate.

Arawn and Ieuan. Dai and Dewi. Merfyn and Maldwyn.

And it’s here that many of them died, often as young as in their 40s, from occupational silicosis.

No health and safety. No silica detection and prevention. No chance.

It makes the work we do at Trolex all the more personal and all the more poignant.

And it’s a major part of the reason we’ve worked so hard to solve the age-old problem of occupational silicosis.

So that modern-day miners and quarry workers – in fact, anyone who might come into contact with silica in their working lives, from construction workers to plasterers, factory workers and stonemasons – will never have to suffer the same fate as my forefathers.

And all it took was vision and ingenuity, optimism and grit, and endless trips to the bank manager. And despite being told we’d never do it – we’ve done it.

New real-time dust monitoring technology that offers new hope to people who previously had no hope of avoiding an unnecessary, painful and premature end to their lives caused by occupational lung diseases.

It’s called the AIR XS Silica Monitor.

And it’s astonishing.

The world’s first real-time silica detection technology saving lives all over the world – made of legends.

As they used to say in the back bar at the Miners Inn in Blaenau…

Dyma i chi fechgyn!*

Drop me a line and I’ll tell you everything you need to know about the AIR XS Silica Monitor and the many ways it can benefit your staff and your business.

*Here’s to you, boys!