Our AIR XS Silica Monitor, an innovative real-time respirable silica (RCS) monitoring device, has been deployed at a major railway operations project to monitor the levels of RCS which workers may be exposed to.

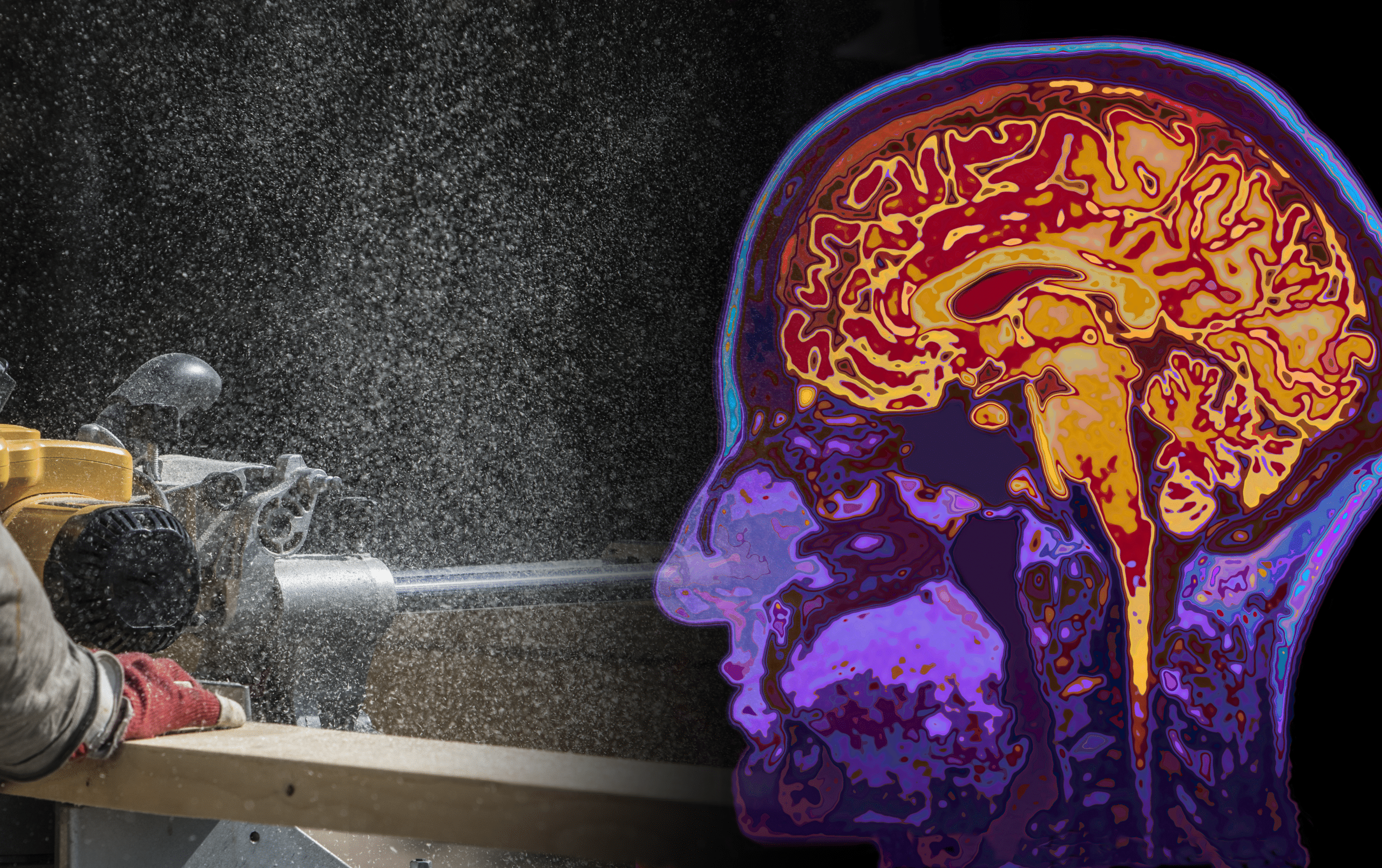

The Central Rail Systems Alliance (CRSA), an alliance between Network Rail, Balfour Beatty, AtkinsRéalis and TSO have been using an AIR XS unit to monitor the levels of RCS released when damaged rail tracks are replaced; when rail track is damaged or needs replacing, the ballast surrounding the track is disturbed and can release RCS. The AIR XS unit was supplied by our UK partners Sunbelt UK & Ireland.

The challenge faced by CRSA was to measure the level of RCS and accompanying dust being released into the atmosphere during the unearthing process of 425m rail and ascertain the level of risk associated for those working in the immediate and surrounding environments. The AIR XS unit was manoeuvred around the site in-line with project progress, so that working scenarios can be accurately represented in the data set.

Upon conclusion of the project, Madeline Dunn, the Health and Safety Advisor for CRSA praised the monitoring and recording capabilities of the AIR XS, saying “We have completed trials prior, however this is the only unit where it is measuring silica and not just general dust levels. We gained the knowledge that the exposure levels were actually higher than we anticipated with even low-level ballast disturbance.”

Thanks to the team at Sunbelt Rentals UK & Ireland for the in-depth case study which you can read in full here.

Have you heard of the ‘psychological contract’? It’s the unwritten understanding of the interaction between you, your workplace environment and your colleagues.

We all have a psychological contract with our employers, whether we know it or not.

As well as considering the physical aspects of your work environment, your psychological contract includes things like the quality of relationships you have with the people you work with, whether you feel properly listened to and understood and know what’s expected of you in your role.

An important part of that contract is ‘psychological safety’. How safe or unsafe your psychological contract leaves you feeling at work.

A term coined in 1999 by organisational behavioural scientist, Amy Edmondson, ‘psychological safety’ includes things like trust in your colleagues, your perception of physical threat in your working environment and how you feel about the training and support you get to do your job.

Unsurprisingly, the safer people feel at work, both physically and emotionally, the more productive they are.

By the same token, if people feel unsafe, then not only are they less productive, but the time the trouble and expense of having to replace people unhappy in their jobs is huge.

Employee benefits provider Perkbox estimates that ‘disengaged employees are costing the UK economy £340 billion every year in lost training and recruitment costs, sick days, productivity, creativity and innovation.’

So how can you make sure that people in your organisation feel psychologically safe?

The first important step in creating a psychologically safe workplace is to make it as physically safe as possible.

Speaking with Trolex, Occupational Psychologist Catherine Dobson told us, “If an environment is not physically safe, if it’s too hot, too cold, or if it feels too dangerous people feel stressed. We must ask ourselves how do we get the right environment for people with the right kind of training, the right kind of cooperation to make it healthier?

Which is what contributes to making our range of dust monitors, such an important development. These include the AIR XD Dust Monitor, the XD ONE Portable Dust Monitor – our wearable dust monitoring technology, and our AIR XS Silica Monitor for real-time silica dust monitoring.

Not simply because it protects workers from the physical dangers of inhaling lethal respirable dusts, but because armed with the knowledge that they are working safely, people feel psychologically safer too.

Catherine explains how: “In relation to silica and dust monitoring. Because the AIR XS Silica Monitor is new, there’s scope for demonstrating that it works. And people can see that.

Also, because all these dust monitors work in real time, it gives people the trust that an intervention will take place should they be in danger. They can trust in the environment being safe.”

A very good thing for workers on both a physical and emotional level.

And great news, too, for the mining, tunnelling, quarrying, manufacturing and construction companies invested in fulfilling their side of the psychological contract with advanced dust monitoring.

Businesses can then reap the rewards of improved production and better worker retention, so everybody wins.

As strange as this question may sound…have you ever taken a moment to sit down and think about dust? Really think about it? Think about what it actually is, where it comes from, why it exists, and the impact it might have on our lives?

Probably not. And why would anyone? It’s just ‘there’ after all, hanging around, doing its thing. A staple accompaniment to life, only momentarily revealed in a shaft of sunlight or a sneeze, or lying on an expensive piece of machinery waiting to be…dusted.

And while we’re all aware that exposure to dust or particulates can impact health, isn’t it the case that because dust is so small, so ephemeral, and so everywhere, questions of what it actually is, and what it really does, tend to get swept under the carpet?

So here’s a chance to take a closer look at what we’re dealing with when we refer to ‘dust’ and reflect on the significant health implications of exposure to something largely unseen that threatens the lives of many thousands of workers, in many hundreds of different industries around the world.

Dust, or for the purposes of this explanation, particulate matter, is, defined by Greenfacts as, ‘the sum of all solid and liquid particles suspended in air.’

A complex range of components including organic and inorganic particles, such as pollen, soot, smoke, and liquid droplets, particulates can vary greatly in size (from coarse, to fine, to ultrafine), in composition, and in origin.

Many types of particulate are considered hazardous.

Putting dust in the home (composed of about 20–50% dead skin) to one side, about a third of the particulates that make up air pollution are created by vehicles, exhaust fumes, and particles from tyres and brakes.

These coarse particles are made up of broken-up larger particles, with a size ranging from 2.5 to 10 µm (a micron is a millionth of a meter). They are also released by agricultural processes, mining, and burning fossil fuels, as well as naturally through pollen, mould spores, and plants and insects.

While industry and the burning of fossil fuels can produce particles from the release of non-combustible materials, other fine sub-micron particles are produced by the condensation of vapourised materials and atmospheric reactions of sulphur oxides and nitrogen oxides initially released as gases.

These fine particulates between 0.1 µm to 2.5 µm, make up most of the airborne particulate mass and represent the main danger to people living or working in a polluted environment.

Ultra fine particles which are smaller than 0.1 µm make up only a few percent of total particulate mass, though they represent over 90% of the number of particles. They’re largely formed from gases that will often end up coagulating to form a larger particulate.

Worldwide, the main cause of air pollution is coal burning, with dirty air killing more people than smoking, car crashes and HIV/Aids. It also shortens billions of people’s lives by up to six years according to a new report.

The climate crisis too, largely a product of burning fossil fuels, is now making a significant contribution to air pollution through wildfires.

But that doesn’t mean the dangers of inhaling dangerous particulates are limited to smoggy city life or pollution blown cross country from burning forests.

At Trolex, our mission is focused on protecting the millions of people exposed to dangerous workplace dust, mist, fumes, vapour or gas – particulate threats that cover the full spectrum of particulate size.

As we wrote in our The importance of reading the room ebook:

‘Potentially lethal dust is everywhere – from construction dust, to the fibreglass/Glass Reinforced Plastics (GRP) used in loft insulation, and 3D printing that fuses layers and layers of extremely fine dust to create the final shape.

There’s coffee dust, soldering fumes (20% of people soldering or working around solder develop asthma), carbon fibre and plaster related lime, sulphate hemihydrates, silica, and mica dust that leads to asthma, COPD, chronic bronchitis, and emphysema.

There’s cement dust, plus the ubiquitous Amorphous Silica used in car tires, agri chemicals and animal feed, in toothpaste and cosmetics, paint, insulation materials, adhesives, coatings, and printer ink.

There’s biomass dust, dust created by waste disposal and recycling, sawmill wood dust, dust in nail bars, chiropodists, and podiatry clinics, tool sharpening dust and MDF dust particles coated in formaldehyde.’

There’s a huge amount that can be done to protect people from the dangers of inhaling dangerous particulates.

On a national level, governments can actually back up the rhetoric with action, instead of just paying lip service to environmental protection. China’s “war against pollution” that started in 2013 has already, supposedly, reduced levels of fossil fuel pollution by 29%.

But clearly much more needs to be done by politicians and business leaders to transition industry to greener, less damaging energy and manufacturing production. To promote production methods which will reduce the creation of hazardous dust.

Which is why we’re working so hard to both raise awareness of the problem and to put our Trolex AIR XD Dust Monitor, XD ONE Portable Dust Monitor, XD1+ Personal Dust Monitor andAIR XS Silica Monitor in the hands of people on the frontline who we can help protect.

With 12,000 UK, and half a million workers around the world dying every year from preventable diseases directly related to dust and particulate inhalation, our mission is as simple as it’s singularly focused, as it’s important.

It’s this: To educate the world’s construction, mining, tunnelling, heavy and manufacturing industries on the dust and particulate dangers their workers face. Then to make clear the smart, simple, cost effective ways our XD One and other duct monitoring technology can help them protect them. And ultimately…

For every worker exposed to dangerous particulates to have wearable personal dust monitoring equipment by 2031.

Get in touch today to speak to one of our experts about how real-time dust monitoring can help improve your safety processes and keep your workers safe from harmful respirable dusts.

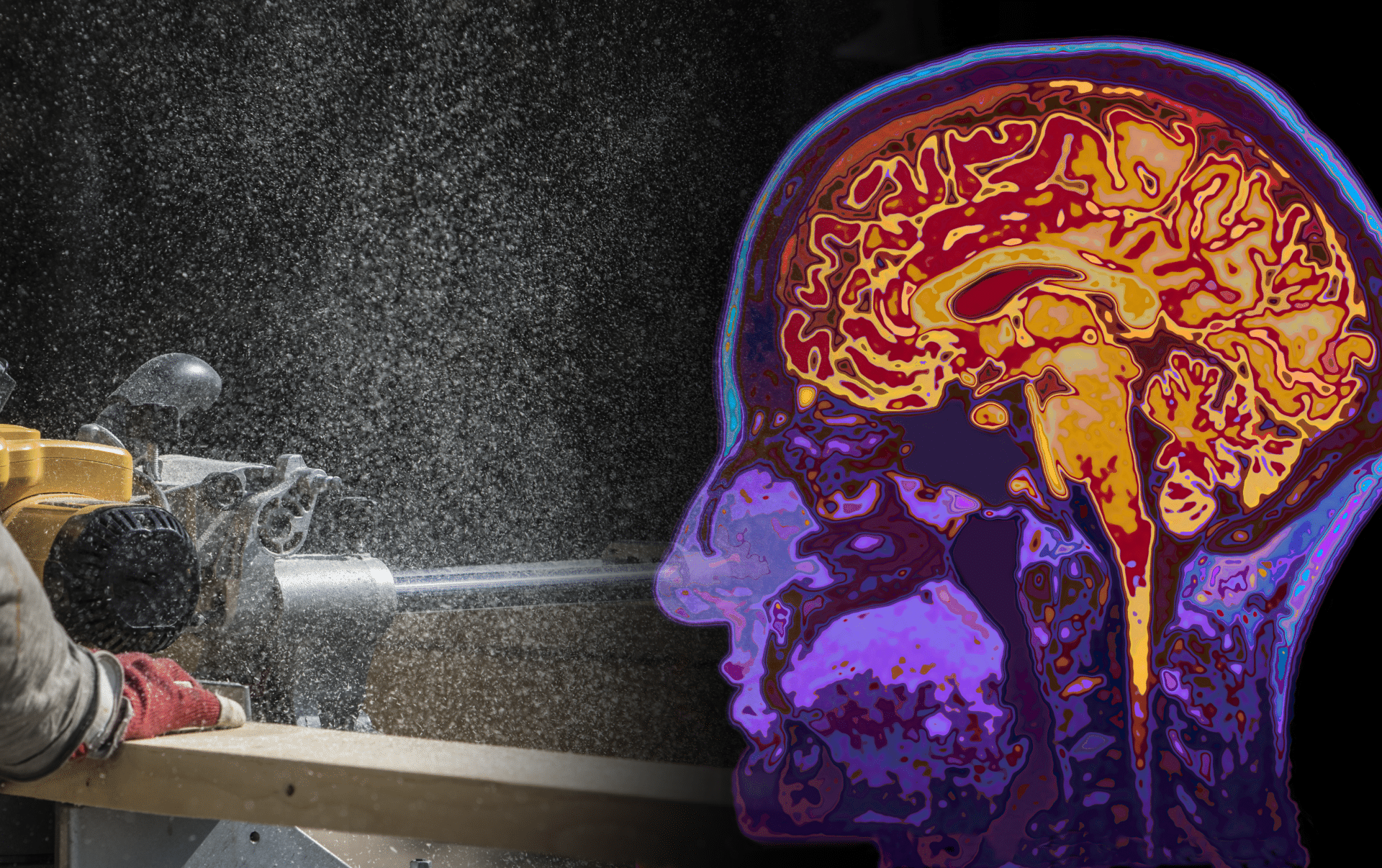

As if the known dangers of exposure to harmful respirable dusts weren’t bad enough, new research is showing that long-term exposure to ambient air pollution is associated with a far wider range of diseases and highlights the importance of particulate monitoring.

Not only are 1.4 million people in the UK reporting ‘lung or breathing problems that were caused or made worse by work,’ and 12,000 people dying every year due to occupational lung diseases, evidence is mounting to show that airborne pollution also causes dementia, strokes and skin cancer.

The study, conducted in the USA and first published in the journal Stroke is titled “Long-Term Exposure to Fine Particulate Matter, Residential Proximity to Major Roads and Measures of Brain Structure“.

Examining the brains of more than 900 people over 60 years old, it revealed that long-term exposure to fine dust causes both brain atrophy (brain shrinkage) and leads to an increased risk of stroke and other disease.

Not only is this news alarming for those who live near busy roads, it also draws attention to the added dangers faced by those working in conditions, and with materials, they may have previously thought safe.

For example, welders, who, despite now using supposedly less dangerous materials and working in spaces where local exhaust ventilation (LEV) is employed, seem to be vulnerable to a far wider range of illnesses than previously thought.

As the report highlighted, even limited exposure of fine dust particles can lead to the heightened risk of cerebrovascular disease and cognitive impairment.

Benjamin Howell on the Fabricator.com says, ‘at the nanolevel, invisible to the human eye, the concentration of particulate matter can pose a great risk to welders. Studies show that welding fume particulates are mostly smaller than 0.1 micrometer, which makes nearly all welding fume particles respirable. They can penetrate deep into the alveolate region of the lungs during inhalation and remain firmly fixed there.’

It’s not all bad news though.

By revealing far greater and far wider reaching dangers than previously acknowledged, the new research means the important issue of how best to protect people from damaging dusts is getting the attention it deserves.

The sheer weight of evidence amassing from the likes of The Journal of Cleaner Production, The British Medical Journal, and Harvard is forcing the hand of governments, regulatory bodies and employers. The necessary steps to protect not just their workers, but every one of us exposed to dangerous airborne pollutants, are being considered and taken. This includes controls, sensors and dust detectors, among other things.

What if a threat could be detected before it even became a threat? What if you could be alerted to the presence of even the smallest of damaging airborne dusts before they had the chance to damage health?

Leading H&S expert John Cairns says:

“The best thing is to detect the hazard before you’re exposed to the hazard. Before you’re exposed to the hazard or a high concentration. You can get the hell out of there, or with the way this new technology works you can set off ventilation systems to clear the area.

The whole ethos behind the Health and Safety Executive (HSE) is to reduce the risk to as low as is reasonably practicable. I think the XD ONE Portable Dust Monitor is adding to that – it’s enhancing the safety system.”

Real-time dust monitoring is an effective way at reducing the risk to workers in hazardous working environments. When combined with RPE, PPE and other equipment, the threats from dust and particle inhalation are reduced drastically. This has a big impact on worker health, morale and productivity.

Send us a message today to find out more about our work to help organisations like yours protect your people from the threat of damaging dust particles with sensors, dust detectors and systems tailored to your work environment.