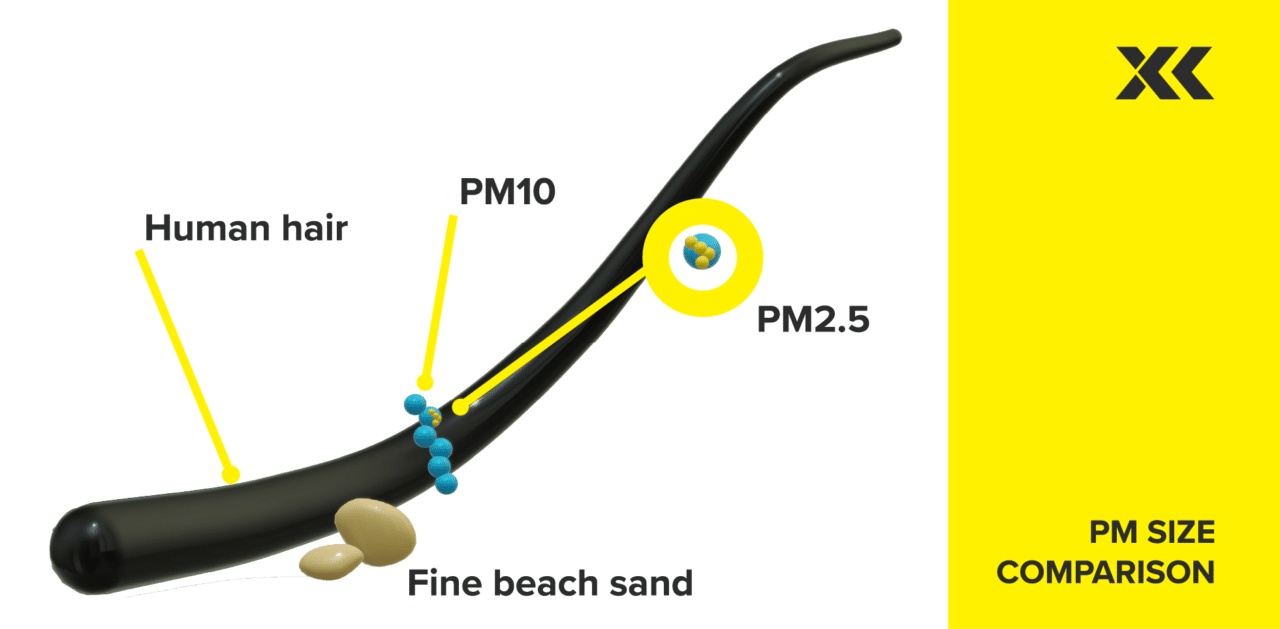

‘PM’ or particulate matter, also known as particle pollution is the term for a mixture of solid particles and liquid droplets found in the air.

It’s estimated that air pollution is linked to 43,000 deaths per year in the UK. Worldwide, at least 7 million people die each year from exposure to air pollution, with 91% of the worldwide population living in locations where the air quality exceeded the World Health Organisations (WHO) air pollution guidelines.

These guidelines state that that annual average concentrations of PM2.5 should not exceed 5 µg/m3 and PM10 should not exceed 15 µg/m3 (both for 24-hour periods). According to the WHO, ‘fine particulate matter at PM2.5 can penetrate through the lungs and further enter the body through the blood stream, affecting all major organs’. Exposure to dust at PM2.5 can cause serious disease to the respiratory system, such as lung cancer and COPD, and also can effect cardiovascular diseases, such as a stroke.

The image below demonstrates PM2.5 and PM10 size in comparison to a single human hair and a grain of sand.

The Department for Environment Food & Rural Affairs (DEFRA), the UK government ministerial department for environment protection, have also highlighted the severity of exposure to air pollution. This growing concern for the UK government estimated in 2010 that the cost of health impacts of air pollution was likely to exceed estimates of £8bn to £20bn.

Although between 2005 and 2022, the UK’s PM2.5 emissions decreased by 41%, emission levels have been relatively steady with small annual fluctuations in the last decade. Industrial combustion is a major source of PM emissions, as well as emissions from industrial production also playing a major part, which can be linked to heavy-dust industry where hazardous particulates can become airborne. Despite some reductions in PM emissions, the threat still very much remains.

A solution to this is real-time dust monitoring. Real-time particulate monitoring allows people in heavy dust loading environments, including industrial applications, to not only understand, but alert them instantaneously when they are exposed to dangerous levels of air pollution. For example, our AIR XD Dust Monitor can alert people in real-time when legislative levels of µg/m3 are breached, over a time-weighted average (TWA) 8-hour period, for both PM2.5 and PM10.

This technology not only offers a simple solution to individuals at high risk of exposure to air pollution by providing instant alerts, but also can help to prevent exposure in the future, as at-risk individuals can learn exactly when and where exposure to air pollution is highest and will likely occur. Thanks to real-time monitoring, both in the UK and Worldwide, we can reduce exposure to air pollution.

You may have seen The All Party Parliamentary Group (APPG) for Respiratory Health report ‘Silica – the next asbestos’ released in March 2020?

In it, it states:

“Construction workers are still 100 times more likely to die from a preventable occupational disease than from an accident. We also know that approximately 12,000 deaths in the industry each year are linked to exposure to dust and chemicals.”

“Figures from IOSH show that roughly half a million people are exposed to RCS at work in the UK. They estimate that in Europe as a whole, 81% of these are employed in construction or in manufacturing products used in that industry.”

Experts at Trolex brought our new technology to the APPG’s attention and explained our nine-year silica detection R&D project that resulted in development of the new real-time silica monitor – work that we’d kept closely under wraps until mid 2021.

The original report refers to Workplace Exposure Limits (WELs) of dust. It says:

“Dust monitoring is vital. Technology advances mean that new methods of real-time exposure level monitoring are now possible. Knowing what the actual exposure levels are is important as exposure will depend on the actual task (e.g. cutting concrete is higher risk than breaking concrete, and the actual exposures depend on the concrete mixture).

“The new Code of Practice for Tunnelling […] that requires the use of new technology which is just becoming available and gives an instantaneous measurement.”

The instantaneous measurement the report refers to is the measurement of a variety of dust and particulates (something we already do with our AIR XD Dust Monitor and XD One Portable Dust Monitor, XD1+ Personal Dust Monitor products) – not specifically silica. Silica always being too difficult to uniquely identify.

Until now.

Our new silica-specific monitoring technology is a game changer.

By working with the authors of the APPG to share the features, benefits and thinking behind the new real-time silica monitoring technology they’ve been able to update the report with new advice on how to best protect workers from the dangers of respirable crystalline silica (RCS).

When it comes to occupational health and safety, new real-time dust monitoring such as the XD ONE Portable Dust Monitor can help to make decisions for the hierarchy of controls.

In this e-book we explain how the arrival of affordable, real-time monitoring, and both wearable and portable dust monitoring technologies promote this new awareness of the dangers of dust in a far broader range of working environments.

Employers and the health and safety community are now shifting their attention. Where they’ve traditionally focused on safety, they now look at the major impacts on long-term health associated with working in hazardous environments.

There’s also an increasing awareness of the range of industries that can present long-term health hazards through the inhalation of dangerous dust particles, from traditional industrial environments to commercial activities.

The HSE are reporting an estimated 1.4 million people in the UK report ‘lung or breathing problems that were caused or made worse by work’ – and whilst it’s great that people are starting to pay more attention to this issue, there’s plenty of room for improvement.

Whilst financial costs of lung diseases effect both businesses and individuals, respiratory diseases are more than just an economic drain. It’s a personal tragedy, and there are a whole raft of occupations and jobs where people are exposed to dangerous dust across the world.

However, through the hierarchy of controls, businesses can determine the most effective solutions in order to keep workers protected from dangerous dust exposure.

Knowing that dangerous dust exists, knowing its effects are potentially lethal, and knowing that the damage it causes is preventable, only takes you so far. Knowing how to prevent that harm is what matters, and this is how the hierarchy of controls can help businesses become more efficient, by understanding how effective each method is in benefitting the workforce.

Fortunately, new accurate, real-time, fixed, wearable and portable dust and silica monitoring sensors are leading the detection charge across every use case. By precisely reading the real-time dust load in any given environment, and the enemy now ‘visible’, businesses can begin to apply the hierarchy of controls in a far more meaningful way.

Congratulations to the New South Wales Government for the foresight and resolution in driving through new legislation to protect workers from the hazards of silica, coal dust, and diesel particulates.

Speaking to Australian Mining, the state’s Deputy Premier and Minister responsible for resources John Barilaro said, “The decision to fast-track these more stringent standards for coal dust exposure was an easy one and is a great example of mine workers, mine operators and government working together to ensure we have robust frameworks in place to address this insidious disease.”

The legislation, which took effect from July 1st 2021, is hugely ambitious too. The legal exposure limit to respirable coal dust was reduced from 2.5 to 1.5 mg/m³ and respirable crystalline silica from 0.1 to 0.05 mg/m³. A new diesel exposure standard of 0.1 mg/m³ commenced 1 February 2021.

Compare the New South Wales Government’s to recent legislation in other parts of the world, and you can see how progressive the New South Wales Government has been. For example, in the United States where OSHA reduced the respirable crystalline silica permissible exposure limit (PEL) affecting the construction, manufacturing, and fracking industries from an allowable average of 250 micrograms per cubic meter of air over an eight-hour shift to 50 micrograms per cubic meter.

In the UK, respirable crystalline silica (RCS) control measures need only be effective in keeping exposure below the Workplace Exposure Limit (WEL) at the old NSW level of 0.1 mg/m³ respirable dust, averaged over eight hours.

With efforts underway to determine whether these levels might be made even more stringent, the good work is clearly an ongoing priority.

As The New South Wales Resources Regulator says in its compliance priority January-June 2021 report. ‘With the implementation of the revised exposure standards for silica and respirable dust, and a new exposure standard for diesel exhaust emissions, airborne contaminants was a priority project between July and December in 2020 and will continue to be a focus area.’

But it’s one thing to bring new, more stringent particulate exposure regulations onto the statute book. It’s another matter altogether making sure they are adhered to.

For a start, guidance needs to be shared with business owners and operators to help them properly implement effective health control plans in the context of the new regulations.

And what about the technical implications? With legal limits (quite rightly) ever shrinking, how can businesses be absolutely confident that the technology they use onsite to measure exposure to harmful dust and particulates is accurate, realistically deployable and affordable?

With much of the legacy technology on the market anything but accurate, realistically deployable and affordable, clearly the challenge for technology companies is to step up and find new ways for industry to meet these new standards.

At Trolex we’ve been working tirelessly on meeting these challenges for years.

And now we have.

It’s called the Trolex real-time dust monitoring range of fixed and wearable dust monitors.

You might also call it an overnight 40-year success story, as we’ve turned our vast experience in environmental monitoring in mining and tunnelling, to designing, manufacturing and distributing world leading dust and particulate monitoring technology.

The Trolex AIR XD Dust Monitor and XD ONE Portable Dust Monitor are both designed to detect even the finest of particulates.

Fixed and wearable, real-time analysis of your working environment from the Trolex dust monitoring range giving you a crystal clear understanding of the real particulate threat you face.

Simple to deploy, easy to maintain and super accurate they deliver a practical and affordable way of protecting your workers AND remaining within the law.

Now, whatever the new legislation and however strictly it’s applied, you can be absolutely sure that you have the technology in place to meet all legal and regulatory responsibilities as well as lead a healthy, happy, motivated workforce.

Don’t take chances. Contact us now to find out more about how our AIR XD and XD ONE real-time dust monitoring products – accurate, simple to use, easy to maintain, real-time particulate detection technology can protect your workers in your hazardous environments.

Did you hear about the plane crash that killed everyone on board? Your answer likely depends on where you live.

According to researchers at the University of Oxford: ‘English Wikipedia readers were much more likely to read about North American and European crashes, and Spanish Wikipedia readers were more likely to read about Latin American crashes.

Page views on English and Spanish Wikipedia for North American and Latin American aircraft crashes, respectively, were each about 50 times greater than for African crashes.’

These events are tragic, to be sure, but the deaths from these situations are more generally heard about than others, such as from dust inhalation – despite technology and processes available to help prevent them.

It also depends on when the crash happened, with Royal Society Open Science discovering that irrespective of the crash location and body count, ‘on both English and Spanish Wikipedia, page views dropped in half between three to 10 days after the event’. The decay of novelty as we lose interest in things when they stop being new.

And then there’s how much capacity you have left to care, the concept scholars refer to as the ‘finite pool of worry’.

‘Because people have a limited capacity for how many issues they can worry about at once, as worry increases about one type of risk, concern about other risks may lessen.’ says The Centre for Research on Environmental Decisions.

Proximity. Timing. The competition with other concerns for a limited capacity to impact emotions. It’s a complicated old business. Disaster, its impact, its legacy and even the ways we look at – or away – from it. That’s only talking about sudden disastrous events; the plane crash, typhoon, earthquake, and other similar events.

What about the disaster that inexorably unfolds? The slow-motion cumulative disaster. Disaster that – over time – takes far more lives than the one off tragedies? Or even a succession of one-off tragedies?

What about:

As we’ve seen, it’s human nature to focus on more recent, local, high-profile events. Discreet, distinct, storylines.

However, don’t the disasters we overlook – the slower moving, less attention-grabbing tragedies that play out day after day – deserve our attention too?

The problem of particulate and dust inhalation is widely ignored, so too is the priority in finding viable solutions.

This is why we do what we do at Trolex, and why we’ve set ourselves the challenge of reducing the risk and impact dust inhalation can have on workers around the world who are rarely spoken about.

This is done through the development of technology like the AIR XD Dust Monitor, XD ONE Portable Dust Monitor, XD1+ Personal Dust Monitor and AIR XS Silica Monitor alongside supporting software, to deliver data in realtime and make sure every worker knows the state of air around them.

We haven’t stopped there, however. Our engineers are constantly asking “what can we do so that, in 10 years time, every worker in the world exposed to dangerous particulates is wearing personal dust monitoring?”

This is easier said than done, of course, but it’s a challenge we’re committed to undertaking and beating. As well as setting ourselves the task of overcoming the engineering challenge, we’re having to face those natural ‘hidden in plain sight’ biases discussed above.

We’ve privately funded each project every step of the way – from research and development, to manufacturing and distribution. Every penny.

Not that we mind. In fact, we’re proud to have independently conceived and created our range of real-time dust monitoring products: innovative dust monitoring technology that’s now the envy of the industry.

These products are perfectly capable of helping us meet our 10-year challenge, and in the process save many thousands of lives.

Set against the backdrop of Covid-19 and the billions and billions of pounds spent to combat it, the macabre irony hasn’t been lost on us, that worldwide more people have died inhaling dangerous particulates in the last five years than they have from Covid 19.

Unnecessary deaths that for only a couple of million pounds backing, our technology could still go faster and further in preventing.

Maybe we should call for a lockdown?

We work with businesses around the world to improve the safety of hazardous work environments and give workers a better chance at reducing the risks of dust inhalation. The long term effects can be severe and, while it might not be as obvious or attention grabbing as other tragedies, we’re committed to doing what we can to help those at risk.

If you’d like to know more about our dust monitoring systems and how they can help your worksite, get in touch with our team of experts today.

We’re living through an air pollution emergency. One that’s already claiming thousands of lives and costing billions of pounds. And that news shouldn’t come as a surprise.

We wrote in a recent blog, The threat from particulates: It gets worse about an American academic study: “Long-Term Exposure to Fine Particulate Matter, Residential Proximity to Major Roads and Measures of Brain Structure.”

The report clearly shows the risks that people living over extended periods near busy main roads face from fine dust that causes respiratory diseases, results in brain atrophy (brain shrinkage) and leads to an increased risk of stroke and other disease.

Another academic paper, ‘Air Pollution and Noncommunicable Diseases’ suggests that air pollution may be damaging ‘every organ in the body.’

Unfortunately there was nothing ‘academic’ about the consequences of particulate inhalation for nine year old Ella Kissi-Debrah, whose death in 2013 was caused by ‘acute respiratory failure, severe asthma and air pollution exposure’.

“The whole of Ella’s life was lived in close proximity to highly polluting roads. I have no difficulty in concluding that her personal exposure to nitrogen dioxide and PM was very high,” stated the coroner.

And the really sad thing about Ella and her family’s suffering?

Is that it’s far from unusual.

According to the World Health Organisation, air pollution is the “new tobacco”, killing 7 million people a year and harming billions more.

“No one, rich or poor, can escape air pollution. It is a silent public health emergency.” Dr Tedros Adhanom Ghebreyesus, the WHO’s director general.

More than nine in ten people breathe toxic air and 300 million live where toxic fumes are six times above international guidelines and the health impacts are profound – especially for children.

So what’s going on? How is it possible that so many people suffer so much through filthy, contaminated air?

A rush for profits? For progress? For economic advancement? A lack of technology? Insufficient knowledge? Clarity of thought? Understanding? Will? A short-termism that prioritised wealth over health?

In truth it’s all these factors and more. Reasons, more often excuses, that in the not so distant future people will look back at in horror. A situation where people simply won’t believe that things were allowed to get so bad and stay so bad for so long.

Thankfully, though belatedly, the weight of detailed research, visible interventions from the likes of WHO, an increasingly active green movement and high profile tragedies such as the death of Ella Kissi-Debrah are seeing attention at last turning to the issue of air pollution and how best to tackle it.

So much so that the language of particulates and respiratory health is even entering mainstream use. The government responded to Ella Kissi-Debrah’s death with, “We are delivering a £3.8 billion plan to clean up transport and tackle NO2 pollution, and going further in protecting communities from air pollution, particularly PM2.5 pollution, which we know is particularly harmful to people’s health.’

Which is great.

But while a public recognition of the issue and an ability to deploy the right words in addressing the issue is a positive sign, it’s the ability of governments and industry to actually do something about air pollution that really matters. Action that all of us will be judged on in the future.

Signs are mixed. For example, despite the UK Government’s recognition that we all need to be protected from toxic air, and despite pledging funds to fight that cause, it has so far voted against proposals to put WHO pollution limits into UK law, arguing that they’re ‘uneconomical.’

‘Were you part of the problem or part of the solution?’ we’ll all be asked in the not too distant future.

Which is why we do what we do here at Trolex – to be a very proud and purposeful part of the solution.

Enquire today about our new AIR XD Dust Monitor and XD ONE Portable Dust Monitor in our real-time dust monitoring range – accurate, simple to use, easy to maintain, real-time particulate detection technology that keeps people safe.

In an ideal world, the risk of dangerous airborne particles simply wouldn’t exist in the workplace. We cannot understate how important respiratory protective equipment (RPE) is, even compared to all the other safety technologies available.

The proper application of the Hierarchy of Controls (HoC), though Elimination, Substitution, Engineering, Administration and personal protective equipment (PPE) would mitigate the threat and make sure that everyone was properly protected.

The unfortunate reality is that many workers still face threats from a wide range of hazardous dust and particulates, such as silica, construction dust, fibreglass, wood, asbestos and many more. Respiratory protective equipment is one of the most effective safety technologies against silica dust and other harmful inhalants.

While every stage of the HoC can play an important role in helping to make workplaces safer, it’s the final stage, the PPE/RPE – the provision and proper wearing of suitably selected and fit tested RPE – that presents the biggest challenge.

Why?

Because too often, RPE fails to provide the protection that providers or wearers think it does.

The IPPI test is a good way to make sure the RPE and PPE you provide – or have been provided – is fit for purpose. Before entering any environment where there’s a risk of harmful dust inhalation, it’s important to check whether the RPE is:

The Construction Dust Partnership (an industry collaboration that helps help construction industry contractors, employers, operatives and others manage the risk of exposure to dusts and raise awareness) says, ‘any gaps around the RPE’s edges allow the contaminant-laden air to pass straight to the nose/mouth and be inhaled into the lungs.’

For example, did you know that beards or stubble can severely impact the performance of RPE?

‘If the wearer has stubble where the RPE seals to the face, this will make an adequate seal between the skin and the RPE impossible. A lack of knowledge or understanding on how to wear RPE correctly can often lead to an unrealistic expectation of protection.’

In other words, people are working with a false sense of security. Not only must the RPE be fit for purpose, but proper training and guidance must be provided on its use – like any other piece of health and safety technology or equipment. Better would be for checks to be made before entering areas with hazardous substances.

There’s nothing more dangerous than thinking you’re safe when in reality you’re not. When you’re labouring under the illusion that your RPE is protecting you from harm and all it’s doing is placing you squarely in harm’s way, it’s a big problem.

“People are not so good at assessing exposure to a risk,” says risk perception expert Ann Bostrom, of University of Washington.

It’s something we’ve seen clearly during the Covid pandemic. Masks acting as signifiers of safety rather than providing genuine protection.

A dangerous combination of availability and confirmation bias, the psychology is explained in this Forbes article, drawing comparisons between respiratory protective equipment and seatbelts. It cites a report that shows people drive faster and more recklessly when they wear seatbelts. The same applies to cyclists riding less cautiously when wearing helmets.

So what’s the answer? If industry is consistently failing to apply the Hierarchy of Controls well enough to protect workers, or even worse, lulling workers into a dangerously false sense of security, what can businesses do to properly protect their people?

The answer is surprisingly simple.

Real-time dust monitoring that gives you an accurate, realtime understanding of the dust threat you and your workers face.

Properly detecting previously unseen and undetectable threats – seeing it as a real danger, not abstract – allows you to properly challenge it. And in the process, your RPE reclaims its proper protective value – a specific, contextual and essential value.

To be clear, dust monitoring is not a reason to not wear RPE and PPE, but it can make sure you’re aware when the environment changes and whether your equipment is appropriate for the situation you find yourself in.

Instead of being taken for granted, worn out of habit, ‘just in case’ or ‘because that’s the way we do it,’ RPE transforms from dangerous IPPI to safe APPW.

Instead of IPPI equipment, APPW is respiratory protective equipment that’s:

Get in touch today to find out more about how our new AIR XD Dust Monitor, XD ONE Portable Dust Monitor, XD1+ Personal Dust Monitor and AIR XS Silica Monitor – accurate, simple to use, easy to maintain, real-time particulate detection technology – helps your teams use their RPE more effectively.

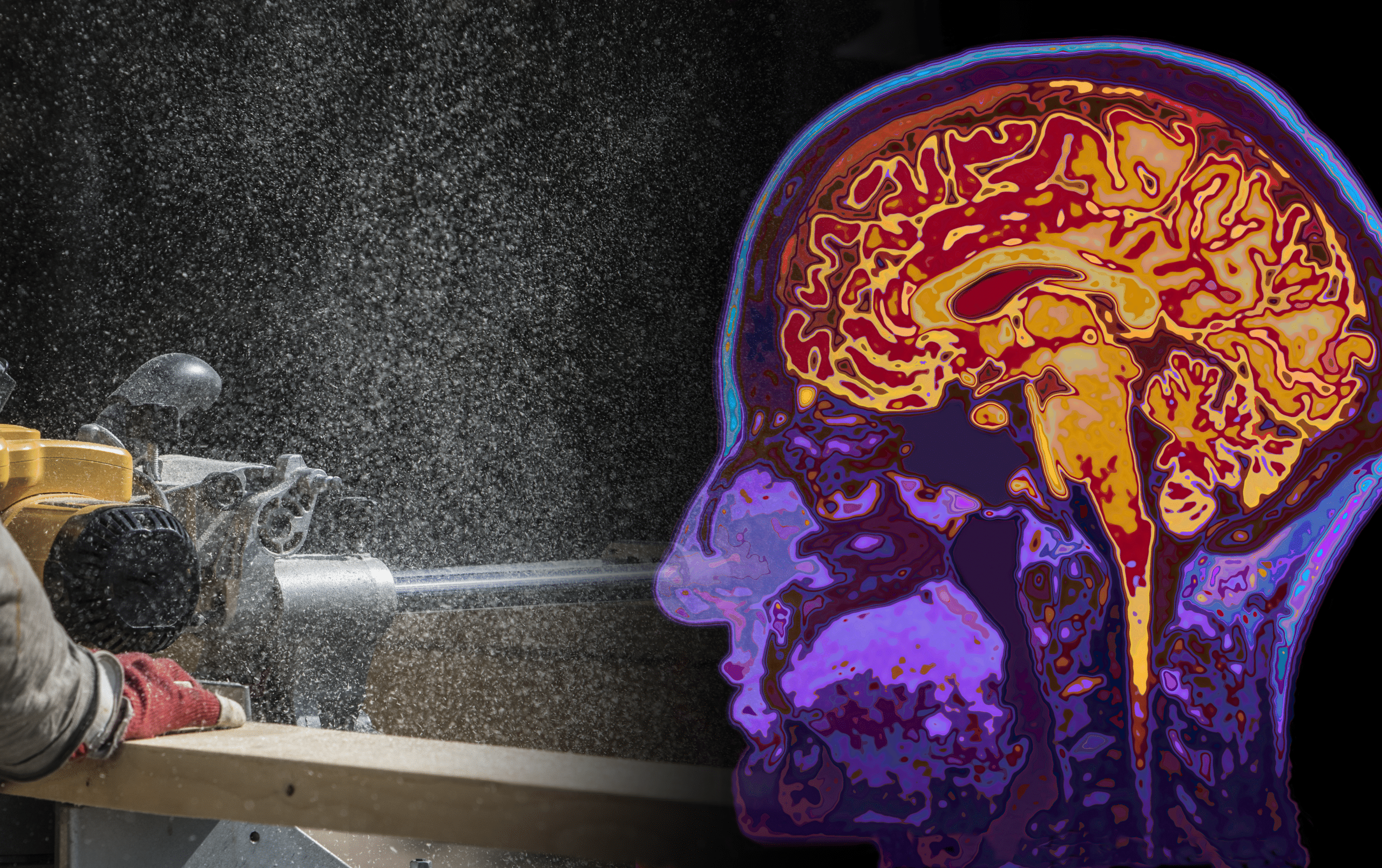

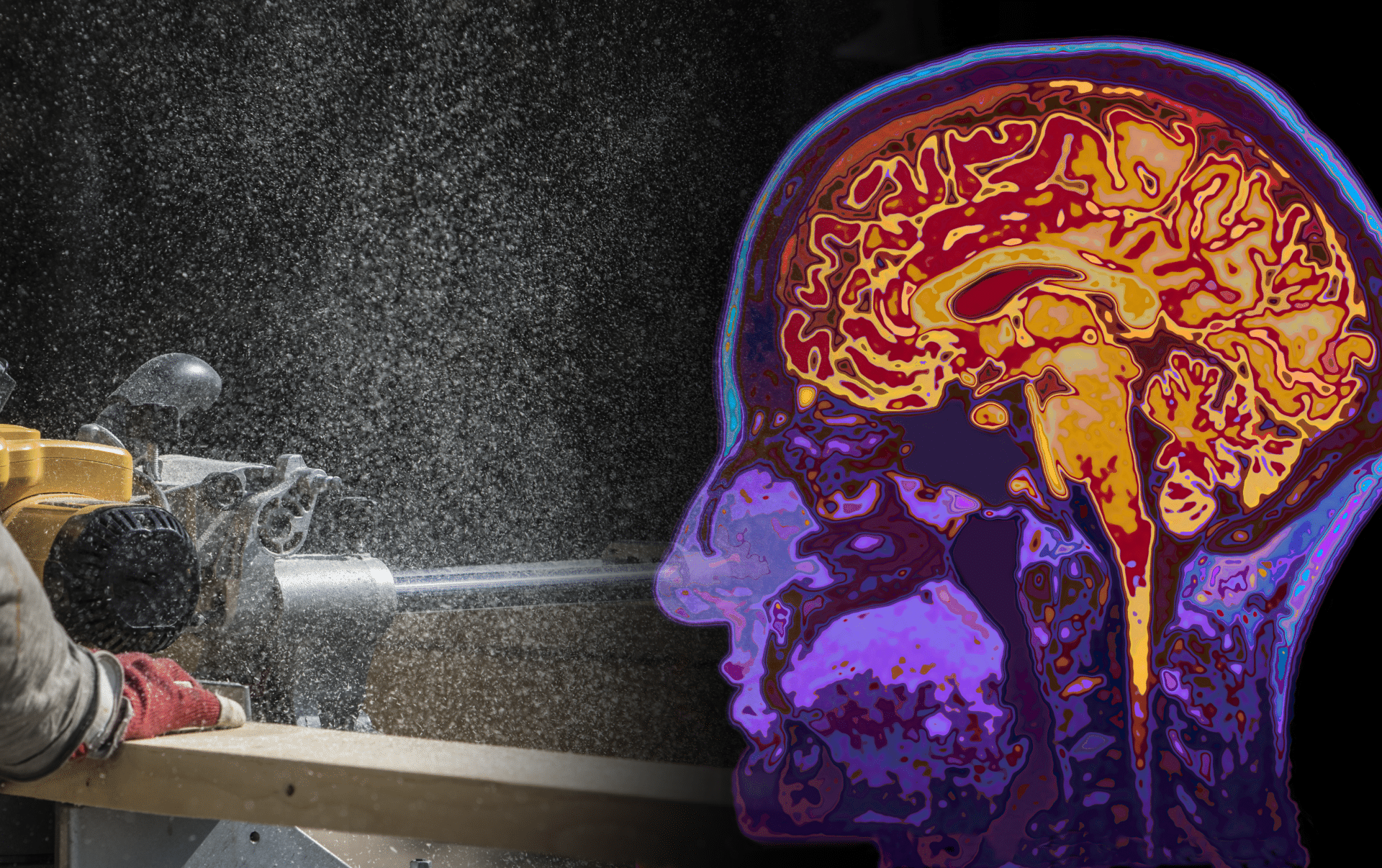

As if the known dangers of exposure to harmful respirable dusts weren’t bad enough, new research is showing that long-term exposure to ambient air pollution is associated with a far wider range of diseases and highlights the importance of particulate monitoring.

Not only are 1.4 million people in the UK reporting ‘lung or breathing problems that were caused or made worse by work,’ and 12,000 people dying every year due to occupational lung diseases, evidence is mounting to show that airborne pollution also causes dementia, strokes and skin cancer.

The study, conducted in the USA and first published in the journal Stroke is titled “Long-Term Exposure to Fine Particulate Matter, Residential Proximity to Major Roads and Measures of Brain Structure“.

Examining the brains of more than 900 people over 60 years old, it revealed that long-term exposure to fine dust causes both brain atrophy (brain shrinkage) and leads to an increased risk of stroke and other disease.

Not only is this news alarming for those who live near busy roads, it also draws attention to the added dangers faced by those working in conditions, and with materials, they may have previously thought safe.

For example, welders, who, despite now using supposedly less dangerous materials and working in spaces where local exhaust ventilation (LEV) is employed, seem to be vulnerable to a far wider range of illnesses than previously thought.

As the report highlighted, even limited exposure of fine dust particles can lead to the heightened risk of cerebrovascular disease and cognitive impairment.

Benjamin Howell on the Fabricator.com says, ‘at the nanolevel, invisible to the human eye, the concentration of particulate matter can pose a great risk to welders. Studies show that welding fume particulates are mostly smaller than 0.1 micrometer, which makes nearly all welding fume particles respirable. They can penetrate deep into the alveolate region of the lungs during inhalation and remain firmly fixed there.’

It’s not all bad news though.

By revealing far greater and far wider reaching dangers than previously acknowledged, the new research means the important issue of how best to protect people from damaging dusts is getting the attention it deserves.

The sheer weight of evidence amassing from the likes of The Journal of Cleaner Production, The British Medical Journal, and Harvard is forcing the hand of governments, regulatory bodies and employers. The necessary steps to protect not just their workers, but every one of us exposed to dangerous airborne pollutants, are being considered and taken. This includes controls, sensors and dust detectors, among other things.

What if a threat could be detected before it even became a threat? What if you could be alerted to the presence of even the smallest of damaging airborne dusts before they had the chance to damage health?

Leading H&S expert John Cairns says:

“The best thing is to detect the hazard before you’re exposed to the hazard. Before you’re exposed to the hazard or a high concentration. You can get the hell out of there, or with the way this new technology works you can set off ventilation systems to clear the area.

The whole ethos behind the Health and Safety Executive (HSE) is to reduce the risk to as low as is reasonably practicable. I think the XD ONE Portable Dust Monitor is adding to that – it’s enhancing the safety system.”

Real-time dust monitoring is an effective way at reducing the risk to workers in hazardous working environments. When combined with RPE, PPE and other equipment, the threats from dust and particle inhalation are reduced drastically. This has a big impact on worker health, morale and productivity.

Send us a message today to find out more about our work to help organisations like yours protect your people from the threat of damaging dust particles with sensors, dust detectors and systems tailored to your work environment.