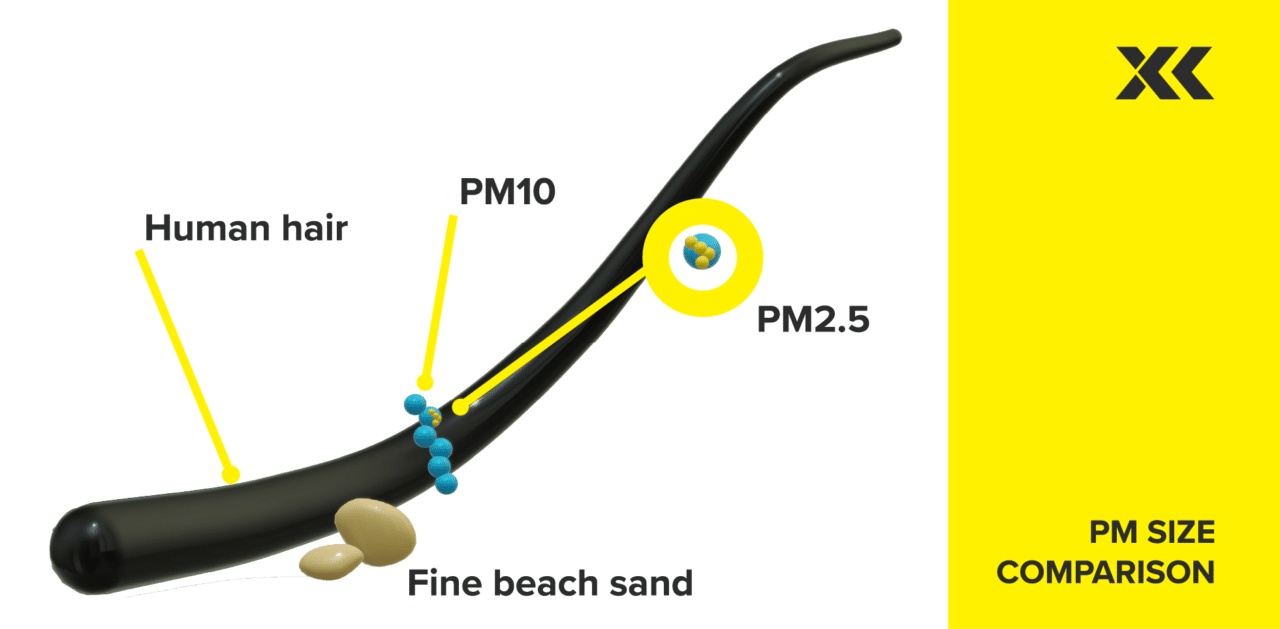

‘PM’ or particulate matter, also known as particle pollution is the term for a mixture of solid particles and liquid droplets found in the air.

It’s estimated that air pollution is linked to 43,000 deaths per year in the UK. Worldwide, at least 7 million people die each year from exposure to air pollution, with 91% of the worldwide population living in locations where the air quality exceeded the World Health Organisations (WHO) air pollution guidelines.

These guidelines state that that annual average concentrations of PM2.5 should not exceed 5 µg/m3 and PM10 should not exceed 15 µg/m3 (both for 24-hour periods). According to the WHO, ‘fine particulate matter at PM2.5 can penetrate through the lungs and further enter the body through the blood stream, affecting all major organs’. Exposure to dust at PM2.5 can cause serious disease to the respiratory system, such as lung cancer and COPD, and also can effect cardiovascular diseases, such as a stroke.

The image below demonstrates PM2.5 and PM10 size in comparison to a single human hair and a grain of sand.

The Department for Environment Food & Rural Affairs (DEFRA), the UK government ministerial department for environment protection, have also highlighted the severity of exposure to air pollution. This growing concern for the UK government estimated in 2010 that the cost of health impacts of air pollution was likely to exceed estimates of £8bn to £20bn.

Although between 2005 and 2022, the UK’s PM2.5 emissions decreased by 41%, emission levels have been relatively steady with small annual fluctuations in the last decade. Industrial combustion is a major source of PM emissions, as well as emissions from industrial production also playing a major part, which can be linked to heavy-dust industry where hazardous particulates can become airborne. Despite some reductions in PM emissions, the threat still very much remains.

A solution to this is real-time dust monitoring. Real-time particulate monitoring allows people in heavy dust loading environments, including industrial applications, to not only understand, but alert them instantaneously when they are exposed to dangerous levels of air pollution. For example, our AIR XD Dust Monitor can alert people in real-time when legislative levels of µg/m3 are breached, over a time-weighted average (TWA) 8-hour period, for both PM2.5 and PM10.

This technology not only offers a simple solution to individuals at high risk of exposure to air pollution by providing instant alerts, but also can help to prevent exposure in the future, as at-risk individuals can learn exactly when and where exposure to air pollution is highest and will likely occur. Thanks to real-time monitoring, both in the UK and Worldwide, we can reduce exposure to air pollution.

We’re excited to bring to the market our XD1+ Personal Dust Monitor as a connected dust monitor with the Reactec Ecosystem.

The Reactec Ecosystem for workplace exposure to hazards includes an IoT gateway, Reactec’s workplace wearable RASOR for secure data transmission, an RFID identity card to personalise the collected dust data and the cloud-based Reactec Analytics software for informative and automatic data dissemination.

RASOR is a communications gateway with integrated SIM and GPS technology to gather data seamlessly from the XD1+ and present it live, personalised and position tracked data to remote line managers via a browser.

Our XD1+ Personal Dust Monitor can be easily connected with RASOR in two different modes for both single worker use and for pairing a number of XD1+ devices to a RASOR connected in hub mode, allowing for flexibility when working, but still providing vital information of worker exposure which can be analysed and interrogated on Reactec’s Analytics platform.

By leveraging revolutionary real-time personal monitoring technology with location tracking, automatic data collection and powerful data analytics, employers can now control their worker’s exposure to harmful respirable dust like never before and reduce these occupational diseases thanks to connected XD1+ and Reactec Ecosystem.

Check our guide for details on the key modes of pairing XD1+ with the Reactec Ecosystem, a run-through of how to connect your XD1+ in these different modes and the benefits of each type of connectivity.

The connected XD1+ Personal Dust Monitor and Reactec cloud-based analytics platform has arrived. The Reactec Analytics platform brings exposure data from the XD1+ to life by delivering real-time updates from individual workers and tracking respirable data to determine where the highest concentration of harmful dust exists in your workplace.

With no filters, pumps, tubes, or replaceable parts, the XD1+ Personal Dust Monitor is one of the most compact, lightweight, and easy-to-use real-time personal dust monitors on the market. For such an accurate and reliable unit, it is also essential to be able to access and easily understand the data which the XD1+ is picking up, minute by minute.

Reactec’s cloud-based analytics platform brings XD1+ exposure data to life by delivering real-time updates from individual workers to remote supervisors, whilst tracking respirable data, to determine where the highest concentration of dust exists in your workplace.

With the support of Reactec’s Ecosystem, the XD1+ is transformed into a connected, personalised dust monitoring device that shares invaluable data insight to key stakeholders and figureheads. The XD1+ is integrated into the Reactec Ecosystem using the Reactec RASOR device as an IoT Gateway to Reactec’s powerful A=nalytics software.

By simply connecting your XD1+ unit to the Reactec Analytics platform you are able to:

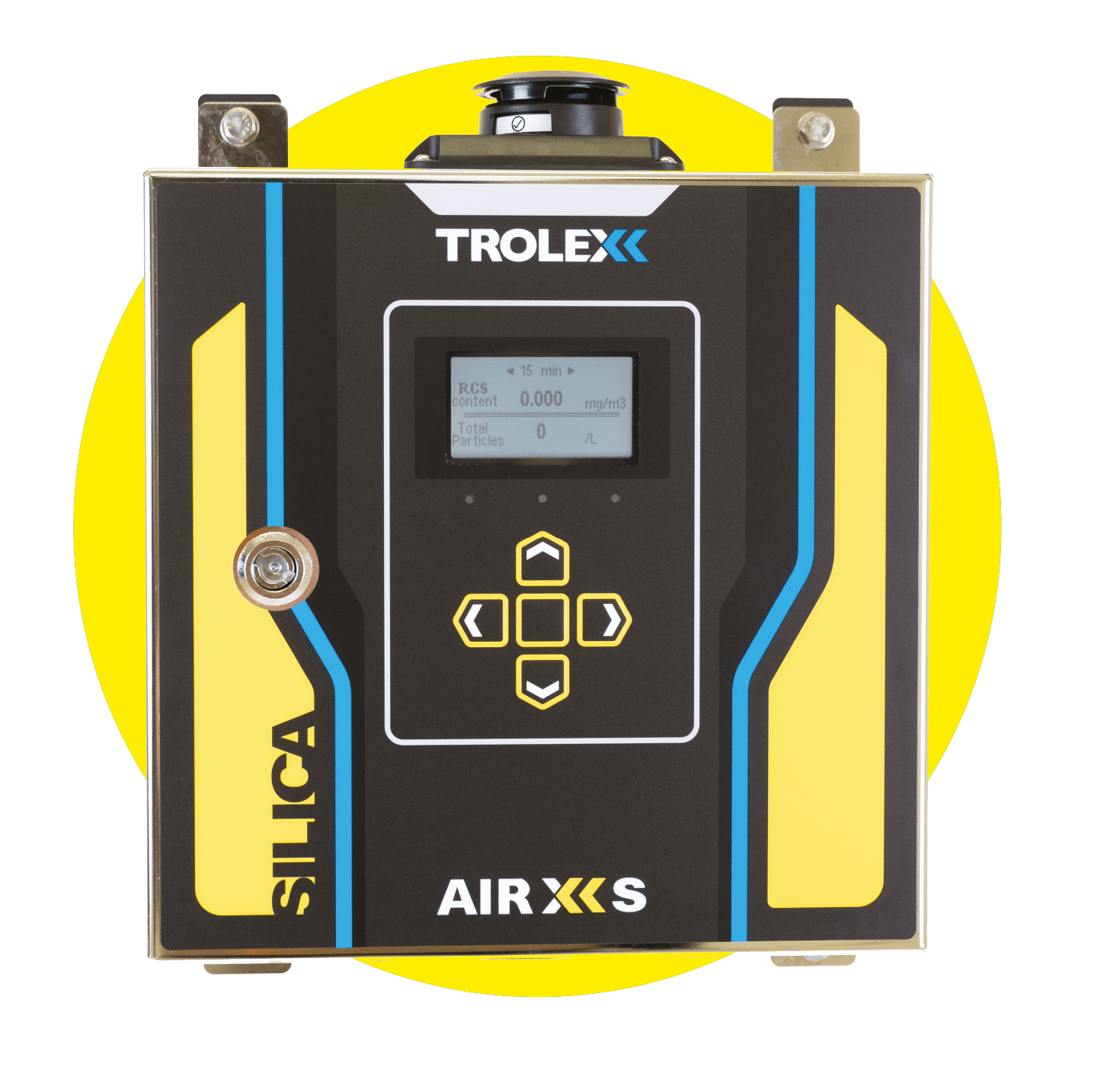

Launched in 2022, the AIR XS Silica Monitor isn’t like other silica monitors on the market. If you’ve been in the Health and Safety space, it’s likely you’ll know about Optical Particle Counter (OPC), also known as “light-scattering”; but our patented AIR XS isn’t just another OPC.

Unlike traditional Optical Particle Counters (OPCs) that rely on light scattering and interruptions to deduce particle size and quantity, the patented Optical Refraction Technology (ORT) used in the AIR XS shines a laser through each particle, capturing its refraction on multiple sensors.

In our blog below, we reference Pink Floyd’s 1973 album Dark Side of the Moon to explain one way to how ORT works. It’s not exact by any means but the refraction of the light coming out of the prism shows an example of how light refracts, similar to a crystalline particle.

The effects of silicosis in the stone industry is not an unknown issue.

But to what extent are stone workers aware of this issue? Are the specific causes of silicosis in the stone industry common knowledge?

A scientific report from nature.com highlights the difference between engineered stone and natural stone, in relation to their silica content, shedding some light on where the cause of silicosis could lie in the stone industry.

Silicosis is one of the most dangerous respirable lung diseases in the workplace, especially when exposure to harmful silica dust is a common occurrence, such as in the stone industry.

It is estimated that globally, 40 to 50 million workers are exposed to silica dust in the workplace.

The Natural Stone Institute guide to awareness and prevention of silicosis determines that exposure to respirable crystalline silica (RCS), specifically in the stone industry comes from cutting or grinding materials, most commonly which contain quartz, is composed of silica dust.

The purpose of the study from nature.com was to see, in relation to RCS, what the most threatening scenario was for worker’s health, in real time, when working with different compositions of stone.

In the study, 12 engineered stones were assessed against three natural stones – white marble, white granites and black granites. By dry-cutting all stones, silica dust was captured in a closed environment and subjected to various assays to determine both chemical and physical properties.

The 12 engineered stones’ silica content varied from one another, and the total RCS content made up of quartz and cristobalite ranged from 70.4% to 90.9%. By comparison, the natural stone’s silica content ranged from 3.5% to 30.1%, marking a clear difference.

As well as this, the dry-cutting of engineered stone generated finer RCS particles with one engineered stone having an average size of as little as 190 nanometres, meaning it could reach deeper in the lungs, in turn causing more damage. Contrastingly, the smallest average particle size of the natural stone was black granite, with an average size of 503 nanometres.

The results of this study concluded that silica dust emissions from engineered stones had a much higher concentration of quartz and cristobalite, therefore having a higher silica content and subsequently more damaging impact on respiratory health.

Ultimately, the report concluded that the higher the silica content of the stone, as well as the smaller size of RCS particles, the more dangerous it is to respirable health.

The Natural Stone Institute conclude in their guide to occupational silicosis that there is no cure for silicosis; however, “with the proper equipment, training, vigilance and continual monitoring, you and your shop floor can be free of the dangers”.

Being aware that harmful silica dust is higher within engineered stone, compared to natural stone, and by monitoring for this, as well as using correct respirable protective equipment (RPE) when working with engineered stone, it allows for correct precautions to be taken to avoid silicosis.

We’ve developed the world’s first real-time silica monitor, the AIR XS Silica Monitor, and, along with other health and safety controls, this is one of the tools that will help to prevent occupational silicosis for those exposed to harmful silica dust in the workplace.

The UK’s favourite DIY and home improvement expert, Tommy Walsh, is calling for more to be done to protect workers from the dangers of silica dust.

Tommy believes that the issue of air quality on building sites should be a national concern, and that silica dust should be viewed the same way as asbestos.

While he became aware of the dangers of silica dust as an issue around five years ago, in relation to the disposal of plasterboard, Tommy says that he has not heard the issue discussed on building sites. This is in spite of the fact that 81% of those regularly exposed to silica dust are construction workers.

Tommy shared that the majority of health and safety concerns on smaller building sites are focused around obvious, external risks, such as falling from a ladder, electricity and water. As a result, he believes that more needs to be done to raise awareness of “invisible” risks, such as occupational silicosis, which is the most common chronic lung disease in the world.

He continued, “over half of the country’s construction is done by small builders and ‘one-man-band’ outfits. Air quality has always been a secondary concern to them, as they don’t know enough about it. Everyone would rather work safe than not safe, but they can’t do that if they don’t have the awareness. Health and safety can often be ignored due to cost-saving, time-saving, or ignorance, but if we can normalise the importance of air quality it will make it harder to ignore.”

Recent data has shown that respirable crystalline silica (RCS) is the biggest risk to construction workers after asbestos, with cases and exposure rising year on year. There are 12,000 deaths a year in the UK from inhalation of dust including silica in the workplace, opposed to just 142 recorded due to workplace accidents between 2020/2021. What’s more, there are an estimated 50,000 workers worldwide exposed to silica dust.

The scale of the issue is not matched by the awareness and action needed to prevent it.

Silicosis, as well as being the world’s most common occupational lung disease, can increase a person’s risk of tuberculosis, kidney disease, arthritis, and lung cancer. The consequences of occupational silicosis have been estimated to cost employers in the UK construction industry over £1 million per year.

In order to raise awareness and protect construction workers from this entirely preventable disease, we’ve launched the AIR XS Silica Monitor, the world’s first real-time silica monitor, which can provide real-time data of dangerous silica dust particles workers are exposed to across any given day.

Requiring no complicated set-up and only five minutes of maintenance a month, the AIR XS is easy-to-use and provides accurate, real-time RCS monitoring with minimal training, letting workers know if the amount of RCS content in their workspace is increasing as they work and when it has risen to dangerous levels.

Protecting the health and safety of the people who work for you is the ethical thing to do. It also makes good business sense as your people are your greatest asset.

But even if you aren’t driven by a moral or financial imperative, governments around the world are toughening up on the legislation that protects workers, so it’s not something any business can afford to ignore.

While some threats are obvious, others are invisible and incredibly hard to accurately detect, such as the deadly silica dust that are the by-product of many industries and manufacturing processes.

Silica dust is linked with severe health problems. It has been dubbed the ‘new asbestos’ and has already been the subject of litigation. Yet it’s something that has historically been impossible to monitor in real time.

Our Construction Industry Health and Safety Survey Winter 2021 shows that employers are concerned about safety, with nine out of 10 respondents recognising that worker safety is important or very important.

But it also revealed that on the ground it can be hard to meet the health and safety challenge, particularly when it comes to dust monitoring, which for a fifth of respondents accounted for half of their safety budget.

This in-depth report looks at how real-time, wearable dust monitoring technology can help to solve the issues from the findings of the Construction Industry Health and Safety Survey Winter 2021.

The findings ultimately mean that it’s clear we need a new approach to dust monitoring. One that looks to the future and is inspired by the intelligent tech revolutionising every other aspect of our lives.

It’s time to act now to tackle danger of hazardous dusts, like silica dust, by investing in smarter solutions to protect the air we breathe, with real-time dust monitoring.

Silica dust is the new asbestos.

But what if it’s not? What if there’s really nothing new about silica dust in relation to asbestos?

The link between the two is even closer than you may think…

Most people know asbestos as the dangerous insulator used in construction, responsible for over 5,000 related disease-deaths per year, typically lung cancer and asbestosis.

However, in its natural form, asbestos is a naturally occurring fibrous silicate mineral.

Put simply, silicate minerals make up asbestos fibres.

Asbestos is actually just one of the many different forms of silicate materials, in the same way that silica dust is.

The similarities between silica dust and asbestos are much closer than people are aware of.

There is a different attitude towards asbestos compared to silica dust.

The dangers of exposure to asbestos are well documented.

Exposure to asbestos can cause serious lung conditions, including asbestosis and mesothelioma. It is the number 1 cause of recorded work-related deaths in the world.

Most people in the UK are aware of its dangers, particularly as asbestos was banned in 1999 for construction work in the UK.

Yet despite all of this, very few people are aware of how dangerous exposure to silica dust is, despite the fact that asbestos fibres are made up of silicate materials, in the same way silica is.

There are many more dangers relating to silica dust than people may be aware of.

Imagine you are working on refurbishing your bathroom and from the grinding of the ceramic sink and a load of dust becomes airborne.

If you were told that this airborne dust which you were inevitably inhaling was asbestos, you’d probably run a mile, right?

And who could blame you? A dust which is responsible for approximately 90,000 asbestos-related diseases per year. You’d want to get as far away from it as possible.

Well, it’s likely that that dust in your bathroom would in fact be silica dust.

A dust which is made up of silicate materials in the same way asbestos fibres are. A respirable dust which is just as lethal, if not more lethal, in comparison to asbestos dust.

But because it isn’t known to people as being the same as asbestos, the dangers seem to be less of a concern to people.

It’s time to get real and become aware of just how dangerous silica dust is.

It is reported that, in crystalline form, respirable crystalline silica (RCS) is responsible for the death of 600 people per year in Great Britain with 450 of those to workers in construction industry. What’s more, an estimated 50,000 workers are exposed to silica dust globally.

The importance of the dangers of silica dust must be realised, especially with what is known about how dangerous asbestos is.

Asbestos is just as lethal as silica dust. The dangers are the same, yet we cannot afford for the results of exposure to silica dust to be the same as what occurred with asbestos.

Silica could be as lethal as asbestos, if not more so, with equally serious consequences.

Being aware of the issue is the start, action must be taken to protect workers from this dangerous dust.

We cannot afford to let history repeat itself.

Based in Salford, M&E contractor Thermatic Homes has more than 70 electricians out in the field rewiring properties for social housing providers including The Wates Group, Unitas, Brunswick Regeneration and Bolton at Home. As an ex-electrician himself, Thermatic MD Karl Wallace is aware of the dust challenges their work creates.

“There are a lot of issues created by dust,” he says. “Chasing through to the brickwork and masonry is extremely intrusive and there’s a huge amount of dust created. We’re conscious that it’s potentially a dangerous environment if not controlled properly.”

Which is why Thermatic electricians always use dust extraction on their CHASE machines. Why they always wear dust masks, always screen doors and why they always hoover, clean, and spray the air with water.

Unlike a traditional building site, it’s not possible to saturate the air in people’s homes with water.

“It’s never ideal,” says Karl, “and being an ex–electrician myself, who’s rewired many a house, you always want to do more. Year on year as more information comes out about the harmful effects of dust, we’re increasingly aware of the dangers and want to do everything we can to prevent them.”

Which is why, when Karl was introduced to the XD One by Trolex MD Steve Holland, he was so keen to get it out on site to trial for dust detection. “What a wonderful idea!” says Karl. “It looks perfect.”

After all, what better way to instantly identify the dust threat than with accurate, real-time dust monitoring and readings? Even better that they’re available on wearable devices his team can just clip on as they work.

A real-time reading of the room designed not just to protect Thermatic workers but also to gain a clear understanding on dust levels that might impact on customers, too.

As important as the XD ONE Portable Dust Monitor is in protecting workers and tenants, using it also sends a very clear message to the industry, not just from Thermatic, but also from the main contractors Thermatic work for.

Very much a “we go above and beyond” message, any main contractor can be rightly proud to do their bit in helping to prevent the 12,000 deaths a year from workplace respiratory disease by using Thermatic and Trolex XD ONE Portable Dust Monitor.

It’s a pioneering approach in the construction industry that really prioritises health and safety and makes clear the commitment to worker and customer safety.

With the XD ONE now onsite as part of a pilot phase to monitor rewiring and upgrade projects, we’ll be reporting back very soon.

Says Karl, “I’m really looking forward to seeing what kind of data the XD ONE gives us, the degree of harm it detects and what we can do about it.”

In the meantime if you want any more information on how the XD ONE can keep your workers and customers safe from the dangers of avoidable dust and particulate inhalation get in touch today.

Silica dust is a problem. A serious problem. In particular, respirable crystalline silica (RCS) – the minute respirable silica dust particles released when working with concrete, bricks, mortar, ceramics, MDF, plywood, stone, ceramics and other similar materials.

Invisible to the naked eye, and 100 times smaller than sand, RCS is fine enough to reach deep inside the lungs. Once there, it causes long term and often fatal damage through silicosis, heart failure, arthritis, kidney disease, Chronic Obstructive Pulmonary Disease (COPD) and even lung cancer.

In the UK, the IOSH reports that half a million workers are exposed to RCS. It contributes to 12,000 lung disease deaths a year – mostly among workers employed in construction or the manufacturing of products for construction.

And RCS isn’t a secret. It’s an acknowledged threat. The HSE (Health & Safety Executive) recognises it as ‘the biggest risk to construction workers after asbestos’ and The All-Party Parliamentary Group for Respiratory Health have released a damning report ‘Silica – the next asbestos’.

The main challenge in combating its dangers is the inherent nature of silica dust itself. The fact that it’s so small, and that as minute shards of irregularly shaped quartz, it’s so hard to detect. The small scale of the particles has made real-time RCS monitoring incredibly difficult, time-consuming, and expensive – which makes the scale of the problem even larger.

Typically, exposure monitoring for RCS has involved occupational hygienists setting up fixed location or wearable instrumentation, including a pump connected to a sampling head that collects samples on a filter. These samples are then sent off to a lab for analysis.

This exposure reporting is then used to determine whether control measures are effective or not and whether an area is safe to work in.

That’s clearly far from ideal.

Analysis is retrospective, reporting on working environments long after workers may already have been exposed to potentially lethal amounts of RCS and is inherently inaccurate. Also, because analysis needs to be carried out by H&S professionals, costs can quickly rocket, with analysis often totalling thousands of pounds a month – and that’s just per survey!

All of this makes the prospect of accurate, affordable, real-time RCS monitoring something of a “Holy Grail” when it comes to protecting workers from this deadly dust.

A Holy Grail that, with strong rumours of a significant breakthrough in silica monitoring soon to hit the market, we’re set to revolutionise RCS detection and the health and safety industry. Eventually, protecting countless workers from unnecessary exposure to potentially lethal silica.

Imagine that. No more clunky, costly, after-the-event analysis and guesswork. Just accurate, affordable, real-time silica monitoring – which will be available in just a few short months.

Curious?

As they say… watch this space.

Get in touch with one of our experts today to discuss how the AIR XS Silica Monitor can improve your safety processes.