‘PM’ or particulate matter, also known as particle pollution is the term for a mixture of solid particles and liquid droplets found in the air.

It’s estimated that air pollution is linked to 43,000 deaths per year in the UK. Worldwide, at least 7 million people die each year from exposure to air pollution, with 91% of the worldwide population living in locations where the air quality exceeded the World Health Organisations (WHO) air pollution guidelines.

These guidelines state that that annual average concentrations of PM2.5 should not exceed 5 µg/m3 and PM10 should not exceed 15 µg/m3 (both for 24-hour periods). According to the WHO, ‘fine particulate matter at PM2.5 can penetrate through the lungs and further enter the body through the blood stream, affecting all major organs’. Exposure to dust at PM2.5 can cause serious disease to the respiratory system, such as lung cancer and COPD, and also can effect cardiovascular diseases, such as a stroke.

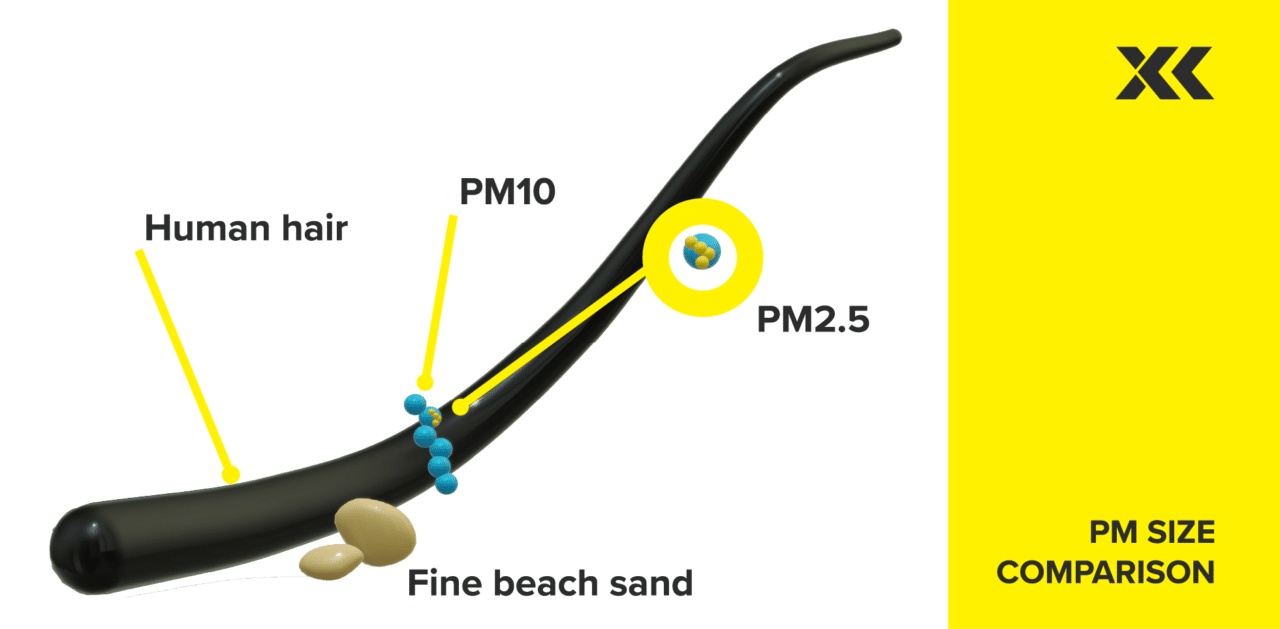

The image below demonstrates PM2.5 and PM10 size in comparison to a single human hair and a grain of sand.

The Department for Environment Food & Rural Affairs (DEFRA), the UK government ministerial department for environment protection, have also highlighted the severity of exposure to air pollution. This growing concern for the UK government estimated in 2010 that the cost of health impacts of air pollution was likely to exceed estimates of £8bn to £20bn.

Although between 2005 and 2022, the UK’s PM2.5 emissions decreased by 41%, emission levels have been relatively steady with small annual fluctuations in the last decade. Industrial combustion is a major source of PM emissions, as well as emissions from industrial production also playing a major part, which can be linked to heavy-dust industry where hazardous particulates can become airborne. Despite some reductions in PM emissions, the threat still very much remains.

A solution to this is real-time dust monitoring. Real-time particulate monitoring allows people in heavy dust loading environments, including industrial applications, to not only understand, but alert them instantaneously when they are exposed to dangerous levels of air pollution. For example, our AIR XD Dust Monitor can alert people in real-time when legislative levels of µg/m3 are breached, over a time-weighted average (TWA) 8-hour period, for both PM2.5 and PM10.

This technology not only offers a simple solution to individuals at high risk of exposure to air pollution by providing instant alerts, but also can help to prevent exposure in the future, as at-risk individuals can learn exactly when and where exposure to air pollution is highest and will likely occur. Thanks to real-time monitoring, both in the UK and Worldwide, we can reduce exposure to air pollution.

The AIR XS Silica Monitor leverages cutting-edge Optical Refraction Technology (ORT) to enhance workplace safety by providing real-time monitoring of respirable crystalline silica (RCS). Unlike traditional particle monitors, AIR XS distinguishes and measures RCS content, enabling immediate detection and response to harmful silica dust levels. This technology is crucial in combating occupational lung diseases such as silicosis, which affects millions of workers globally.

Current monitoring methods, like gravimetric sampling, are time-consuming and often deliver results too late to prevent exposure. In contrast, real-time silica monitoring offers immediate data, significantly reducing the risk of occupational silicosis by enabling prompt action to mitigate hazardous conditions. The importance of such real-time data is highlighted by cases like Joanna McNeill’s, who developed silicosis at the age of just 36. Her story, like many others underscores the necessity for continuous monitoring to protect workers from the threat of silicosis, regardless of their occupational environment.

Our real-time RCS monitor, AIR XS provides a real-time solution to this threat. Workers are not only alarmed and alerted when silica levels exceed legislative limits but can work to best practices by implementing AIR XS with the Hierarchy of Controls, supporting proactive measures to eliminate or minimise exposure to RCS. This move to real-time monitoring as a solution to the threat of silicosis has also been noticed by governing bodies, like the All-Party Parliamentary Group on Respiratory Health.

To learn more about how this real-time solution not only enhances worker safety but also streamlines business operations, click the link below to read the case study in full.

We’re excited to bring to the market our XD1+ Personal Dust Monitor as a connected dust monitor with the Reactec Ecosystem.

The Reactec Ecosystem for workplace exposure to hazards includes an IoT gateway, Reactec’s workplace wearable RASOR for secure data transmission, an RFID identity card to personalise the collected dust data and the cloud-based Reactec Analytics software for informative and automatic data dissemination.

RASOR is a communications gateway with integrated SIM and GPS technology to gather data seamlessly from the XD1+ and present it live, personalised and position tracked data to remote line managers via a browser.

Our XD1+ Personal Dust Monitor can be easily connected with RASOR in two different modes for both single worker use and for pairing a number of XD1+ devices to a RASOR connected in hub mode, allowing for flexibility when working, but still providing vital information of worker exposure which can be analysed and interrogated on Reactec’s Analytics platform.

By leveraging revolutionary real-time personal monitoring technology with location tracking, automatic data collection and powerful data analytics, employers can now control their worker’s exposure to harmful respirable dust like never before and reduce these occupational diseases thanks to connected XD1+ and Reactec Ecosystem.

Check our guide for details on the key modes of pairing XD1+ with the Reactec Ecosystem, a run-through of how to connect your XD1+ in these different modes and the benefits of each type of connectivity.

It’ll come as no great surprise: the more hassle something is, the less people want to do it. A simple fact, from technology, to sport, to entertainment, to business, the ‘more trouble than it’s worth’ factor relates to every aspect of life. There’s even a model that represents it. Fred Davis’ 1986 Technology Acceptance Model (TAM) designed to measure the adoption of new technology based on customer attitudes.

The time, the trouble and the expense of ‘high maintenance’ dust monitoring equipment goes a long way to explaining why it has never really been adopted to the scale that workers truly deserve.

Traditional dust monitoring equipment:

– Takes too much time to deploy

– Needs continual fiddly maintenance

– Costs too much money

– Is often too big, too heavy and too fragile

– Is too much hassle

Which is why we’ve worked so hard to develop, manufacture and distribute the Trolex XD ONE Portable Dust Monitor.

The new, easy-to-use, low maintenance, reliable and accurate personal dust monitor; more like a PPE product than a traditional high-maintenance dust detector or analyser.

Let’s take a look at the Trolex XD ONE Portable Dust Monitor, in particular its ease of use, deployment and maintenance, against the leading products already on the market.

Let’s see how they compare – or more realistically – how they don’t. Because, as you’ll see for yourself, the advantages of the XD ONE are so many and so significant that any genuine comparisons are few and far between.

How easy is the unit to wear, use, and get working?

Trolex XD ONE Portable Dust Monitor: Pick it up. Switch it on. Off you go…and go…and go.

Compared to:

TSI SidePak AM520/520i: Larger and 30% heavier than the XD ONE. Requires different impactors for different particulate sizes that need to be recalibrated as they’re swapped out. Fiddly tube clipping required.

SKC HAZ-DUST IV: Three-times heavier than the XD ONE at 1.4 kg and much larger. Base unit + tube + sampling head clipped near breathing zone with separate filter unit.

CASELLA APEX 2: Requires a clean environment and tweezers to handle the filter. Flow meter and calibration adapter kit not included and needs to be purchased separately.

Nanozen DustCount 9000: Base pump unit with impactors, tube to head unit with filter in cassette and sensor. The usual set-up with the usual problems. Don’t forget to remove the red cap before switching on or you’ll damage the unit!

TM DATA II: Much bigger and 20% heavier.

What kind of burden does the typical maintenance cycle put on the user?

Trolex XD ONE Portable Dust Monitor:

– Five seconds for automatic or on-demand self-testing

– 60 seconds of compliance every six months

– No return-to-base, complex set-up or calibration

– That really is it. PPE for the real world

Compared to:

TSI SidePak AM520/520i:

– Recommended annual return-to-base

– Impactor maintenance – eight-step process

– “Impactor should be cleaned prior to each use.” – TSI website

– Cyclone maintenance – complete disassembly and reassembly

– Separate filter unit required to perform daily calibration check

– Multiple monitors required to bump test in the field. It is very difficult to generate a known aerosol concentration for a ‘bump test’ in the field without very sophisticated equipment. With use of multiple SidePak Monitors running them side by side…if all instruments are within 20% of each other, they are all functioning properly’ TSI website

SKC HAZ-DUST IV:

– 81-page manual

– “Sensor optics to be checked every 48 hours when used in a 2-3 mg/m³ TWA environment and on a weekly or monthly basis in less contaminated environments” – eight-step cleaning process using a bespoke kit

– Flow rate must be checked every time a new gravimetric filter Is used – six-to-eight-step procedure

– Calibration every month as a minimum/when dropped – minimum 11-step procedure

– Annual third-party calibration required

– 19 accessories

CASELLA APEX 2:

– Annual return to base/or after 2,500 hours, whichever is sooner

– Loaded filter or battery voltage reductions affect air flow speed requiring variable flow to be monitored at all times. In-built pressure and temperature compensation, pulsation control, high back pressure and long battery life presented as great ‘features’ of their product when in fact they’re all only necessary because of the antiquated filter-based methodology used

– Inlet filter to be replaced every three months (more often in challenging environments) four-stage process

– Different filters are required for different applications and this needs to be worked out

Nanozen DustCount 9000:

– Recommended annual return to base

– Impactor has to be oiled and cleaned – fiddly with small pipettes of special oil and a three-minute wait before re-assembling and cleaning with a special alcohol substance

– New filters need to be inserted into the filter cartridge. A screwdriver, clean area and tweezers required

– Pump needs to be calibrated. Separate filter unit required to do this

TM DATA II:

– Special calibration kit required

– Measuring chamber cleaned with oil-free pressurised air or with soft dry brush

– Light trap covers can be screwed out so that dust particles can be blown out of the light trap

– Lenses in front of the diodes can be cleaned with Q-tip wetted in alcohol

– Internal calibration and zero-point adjustments should be carried out on regular intervals

– Maintenance and repair only by qualified personnel

The Trolex XD ONE Portable Dust Monitor – a device that’s so easy to use and maintain, so useful, that it’s more hassle to NOT use it.

And when you start to tot up the cost benefits of the XD ONE over its competition, it’s hard to know where to start.

– The time saved in setup

– The hours of maintenance saved

– The savings in extra disposable kit

– Improved site performance

– Lower worker absenteeism

– Recruitment cost savings

– Reduced legal and litigation costs

Perhaps the greatest benefit though is one that can’t be measured in monetary terms – the opportunity to prevent your workers from suffering avoidable, life changing disease, and premature death. Priceless.

There’s a well known sales mantra that goes: “People don’t buy the best – they buy products they can understand the fastest.”

The same principle applies to technology adoption.

People don’t buy the best – they buy products that are easiest to adopt.

The great thing here is that not only are Trolex products the easiest to adopt, they’re more accurate, far simpler to maintain and significantly cheaper to use than anything else in the market. The best.

So, when the question is:

‘How do we best encourage people to use dust monitoring equipment and to keep using it because it’s easy to deploy and easy to maintain?’

The answer is as simple as it’s effective.

The Trolex XD ONE Portable Dust Monitor.

If you’d like to find out how real-time dust monitoring can help improve your safety processes, get in touch today.

Did you hear about the plane crash that killed everyone on board? Your answer likely depends on where you live.

According to researchers at the University of Oxford: ‘English Wikipedia readers were much more likely to read about North American and European crashes, and Spanish Wikipedia readers were more likely to read about Latin American crashes.

Page views on English and Spanish Wikipedia for North American and Latin American aircraft crashes, respectively, were each about 50 times greater than for African crashes.’

These events are tragic, to be sure, but the deaths from these situations are more generally heard about than others, such as from dust inhalation – despite technology and processes available to help prevent them.

It also depends on when the crash happened, with Royal Society Open Science discovering that irrespective of the crash location and body count, ‘on both English and Spanish Wikipedia, page views dropped in half between three to 10 days after the event’. The decay of novelty as we lose interest in things when they stop being new.

And then there’s how much capacity you have left to care, the concept scholars refer to as the ‘finite pool of worry’.

‘Because people have a limited capacity for how many issues they can worry about at once, as worry increases about one type of risk, concern about other risks may lessen.’ says The Centre for Research on Environmental Decisions.

Proximity. Timing. The competition with other concerns for a limited capacity to impact emotions. It’s a complicated old business. Disaster, its impact, its legacy and even the ways we look at – or away – from it. That’s only talking about sudden disastrous events; the plane crash, typhoon, earthquake, and other similar events.

What about the disaster that inexorably unfolds? The slow-motion cumulative disaster. Disaster that – over time – takes far more lives than the one off tragedies? Or even a succession of one-off tragedies?

What about:

As we’ve seen, it’s human nature to focus on more recent, local, high-profile events. Discreet, distinct, storylines.

However, don’t the disasters we overlook – the slower moving, less attention-grabbing tragedies that play out day after day – deserve our attention too?

The problem of particulate and dust inhalation is widely ignored, so too is the priority in finding viable solutions.

This is why we do what we do at Trolex, and why we’ve set ourselves the challenge of reducing the risk and impact dust inhalation can have on workers around the world who are rarely spoken about.

This is done through the development of technology like the AIR XD Dust Monitor, XD ONE Portable Dust Monitor, XD1+ Personal Dust Monitor and AIR XS Silica Monitor alongside supporting software, to deliver data in realtime and make sure every worker knows the state of air around them.

We haven’t stopped there, however. Our engineers are constantly asking “what can we do so that, in 10 years time, every worker in the world exposed to dangerous particulates is wearing personal dust monitoring?”

This is easier said than done, of course, but it’s a challenge we’re committed to undertaking and beating. As well as setting ourselves the task of overcoming the engineering challenge, we’re having to face those natural ‘hidden in plain sight’ biases discussed above.

We’ve privately funded each project every step of the way – from research and development, to manufacturing and distribution. Every penny.

Not that we mind. In fact, we’re proud to have independently conceived and created our range of real-time dust monitoring products: innovative dust monitoring technology that’s now the envy of the industry.

These products are perfectly capable of helping us meet our 10-year challenge, and in the process save many thousands of lives.

Set against the backdrop of Covid-19 and the billions and billions of pounds spent to combat it, the macabre irony hasn’t been lost on us, that worldwide more people have died inhaling dangerous particulates in the last five years than they have from Covid 19.

Unnecessary deaths that for only a couple of million pounds backing, our technology could still go faster and further in preventing.

Maybe we should call for a lockdown?

We work with businesses around the world to improve the safety of hazardous work environments and give workers a better chance at reducing the risks of dust inhalation. The long term effects can be severe and, while it might not be as obvious or attention grabbing as other tragedies, we’re committed to doing what we can to help those at risk.

If you’d like to know more about our dust monitoring systems and how they can help your worksite, get in touch with our team of experts today.