‘PM’ or particulate matter, also known as particle pollution is the term for a mixture of solid particles and liquid droplets found in the air.

It’s estimated that air pollution is linked to 43,000 deaths per year in the UK. Worldwide, at least 7 million people die each year from exposure to air pollution, with 91% of the worldwide population living in locations where the air quality exceeded the World Health Organisations (WHO) air pollution guidelines.

These guidelines state that that annual average concentrations of PM2.5 should not exceed 5 µg/m3 and PM10 should not exceed 15 µg/m3 (both for 24-hour periods). According to the WHO, ‘fine particulate matter at PM2.5 can penetrate through the lungs and further enter the body through the blood stream, affecting all major organs’. Exposure to dust at PM2.5 can cause serious disease to the respiratory system, such as lung cancer and COPD, and also can effect cardiovascular diseases, such as a stroke.

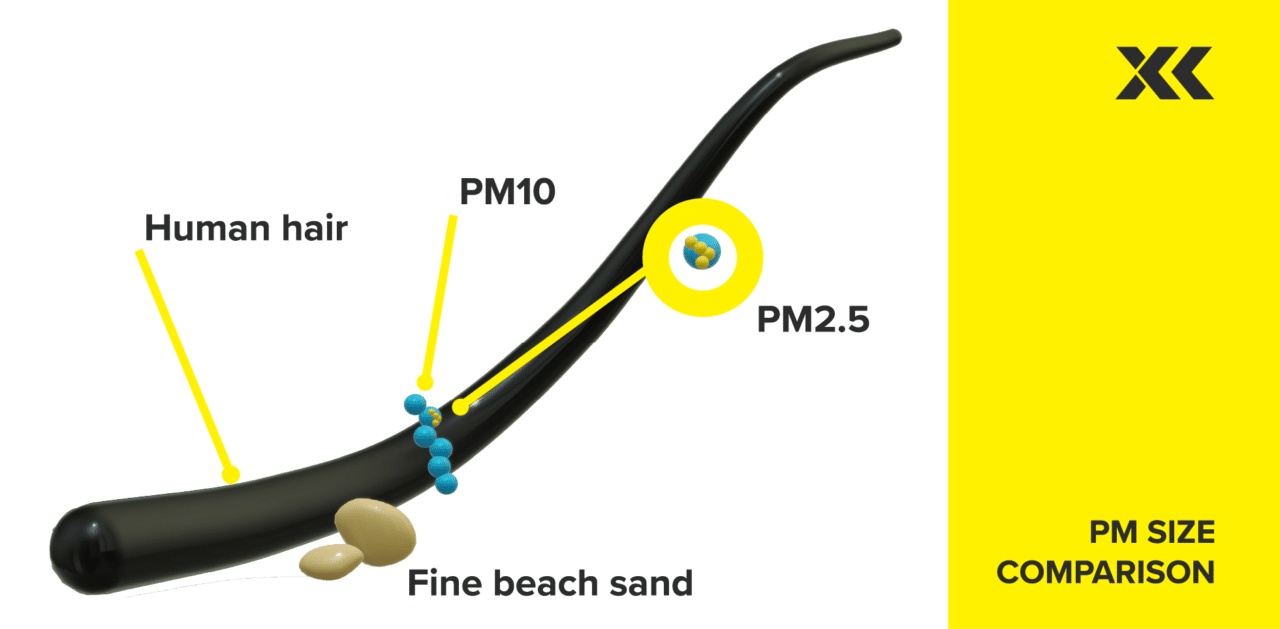

The image below demonstrates PM2.5 and PM10 size in comparison to a single human hair and a grain of sand.

The Department for Environment Food & Rural Affairs (DEFRA), the UK government ministerial department for environment protection, have also highlighted the severity of exposure to air pollution. This growing concern for the UK government estimated in 2010 that the cost of health impacts of air pollution was likely to exceed estimates of £8bn to £20bn.

Although between 2005 and 2022, the UK’s PM2.5 emissions decreased by 41%, emission levels have been relatively steady with small annual fluctuations in the last decade. Industrial combustion is a major source of PM emissions, as well as emissions from industrial production also playing a major part, which can be linked to heavy-dust industry where hazardous particulates can become airborne. Despite some reductions in PM emissions, the threat still very much remains.

A solution to this is real-time dust monitoring. Real-time particulate monitoring allows people in heavy dust loading environments, including industrial applications, to not only understand, but alert them instantaneously when they are exposed to dangerous levels of air pollution. For example, our AIR XD Dust Monitor can alert people in real-time when legislative levels of µg/m3 are breached, over a time-weighted average (TWA) 8-hour period, for both PM2.5 and PM10.

This technology not only offers a simple solution to individuals at high risk of exposure to air pollution by providing instant alerts, but also can help to prevent exposure in the future, as at-risk individuals can learn exactly when and where exposure to air pollution is highest and will likely occur. Thanks to real-time monitoring, both in the UK and Worldwide, we can reduce exposure to air pollution.

A manufacturer of prestigious natural stone, Burlington Stone have quarried for over 200 years across the English Lake District, extracting and crafting a diverse range of signature British natural slate and stone products.

Individuals across their workforce are often exposed to hazardous substances, most notably airborne dust, including silica dust. Burlington Stone trialed two XD1+ devices on their site for a month to see how real-time, personal dust monitoring would improve their safety processes.

After the trial, we spoke to Health and Safety Manager, Peter Walker, about the success of the trial and some of the major benefits which Burlington Stone’s workforce found deploying XD1+ Personal Dust Monitor units in their day-to-day processes.

You may have seen The All Party Parliamentary Group (APPG) for Respiratory Health report ‘Silica – the next asbestos’ released in March 2020?

In it, it states:

“Construction workers are still 100 times more likely to die from a preventable occupational disease than from an accident. We also know that approximately 12,000 deaths in the industry each year are linked to exposure to dust and chemicals.”

“Figures from IOSH show that roughly half a million people are exposed to RCS at work in the UK. They estimate that in Europe as a whole, 81% of these are employed in construction or in manufacturing products used in that industry.”

Experts at Trolex brought our new technology to the APPG’s attention and explained our nine-year silica detection R&D project that resulted in development of the new real-time silica monitor – work that we’d kept closely under wraps until mid 2021.

The original report refers to Workplace Exposure Limits (WELs) of dust. It says:

“Dust monitoring is vital. Technology advances mean that new methods of real-time exposure level monitoring are now possible. Knowing what the actual exposure levels are is important as exposure will depend on the actual task (e.g. cutting concrete is higher risk than breaking concrete, and the actual exposures depend on the concrete mixture).

“The new Code of Practice for Tunnelling […] that requires the use of new technology which is just becoming available and gives an instantaneous measurement.”

The instantaneous measurement the report refers to is the measurement of a variety of dust and particulates (something we already do with our AIR XD Dust Monitor and XD One Portable Dust Monitor, XD1+ Personal Dust Monitor products) – not specifically silica. Silica always being too difficult to uniquely identify.

Until now.

Our new silica-specific monitoring technology is a game changer.

By working with the authors of the APPG to share the features, benefits and thinking behind the new real-time silica monitoring technology they’ve been able to update the report with new advice on how to best protect workers from the dangers of respirable crystalline silica (RCS).

It’s amazing how often a product created to solve a specific problem in one marketplace goes on to be adopted in others.

We’ve all heard of the NASA ‘spinoffs’ – the 1,300 documented NASA technologies now used across the world. From memory foam, to GPS, to scratch resistant sunglasses, to cordless vacuum cleaners; the list goes on…and on. You don’t have to look too hard to spot crossover successes – the law of unintentional consequence going about its business in the most constructive of ways.

In a B2B context, you could apply the same principle to the Trolex XD ONE Portable Dust Monitor.

The wearable dust monitor, XD ONE, was originally developed as an evolution of our AIR XD Dust Monitor, a fixed dust monitoring device for the mining, tunnelling and quarrying industries. Industries infamous for their creation of dangerous respirable dusts. But now it’s finding a whole new audience in lighter, less obvious industries such as baking, woodworking, paper manufacturing, motor engineering, highway maintenance and especially construction.

If the interest shown at the recent Safety in Construction Show is anything to go by, there’s now a real desire to learn more about the XD ONE Portable Dust Monitor, and the life-saving protection it gives workers all across the construction industry.

Organisations such as the Health & Safety Executive (HSE) are doing their best to inform and educate the construction industry of the threats of dangerous particulates. But, as feedback from The Safety in Construction Show made clear, it’s the more visible, more immediate threats that attract the headlines. Trips, slips, fire or explosions tend to attract attention, with dust related tragedies rarely treated with the same degree of importance.

It’s one reason why we work so hard to get in front of the industry. To educate construction specialists (especially senior management) on the long-term impacts of dangerous exposure to construction dust and particulates.

The other reason? To make clear that the solution exists right here, right now – with the XD ONE, personal dust monitoring by Trolex.

As we’ve written before, ‘just because you can’t see a threat doesn’t mean it doesn’t exist.’

And while great plumes of rock or coal dust present an obvious, visible risk to workers, what about those particles that are so small, we mistakenly think they’re not even there? What about the invisible, previously undetectable threats?

With our XD ONE Portable Dust Monitor able to measure even the smallest of microscopic construction dust to 0.38 nanometers, if it’s there, the XD ONE will tell you in real time.

Instead of presuming an area safe because there’s no obvious sign of dust, we can measure it as safe – or not.

And importantly, because the XD ONE Portable Dust Monitor measures in real time, it means that instead of being alerted to exposure after the event, you can manage processes ‘live’ to keep your people safe and your business efficient.

As much as anything, it’s the fact that the XD ONE Portable Dust Monitor is wearable, that’s changing the whole dynamic of dust detection – especially for the construction industry.

Our personal and wearable dust monitor is so small, so light and so low maintenance that workers quickly forget they’re even wearing it. It has transformed life-saving dust detection from an expensive, time consuming and cumbersome hassle (too often neglected or even plain ignored), into a Health and Safety no-brainer for any business serious about worker welfare.

An important life saving device for the mining, tunnelling and quarrying industries, crossing over to save lives in the construction industry.

If you work in construction and want to find out more about the XD ONE, just get in touch today. We’ll tell you everything you want to know about protecting you and your teams on your construction sites.

It’s the twenty-first century, and we are in “the age of data”. Everything is data-driven from what we do and use. Even the devices we carry around with us all day, like our mobile phones, and most recently, even smart watches are mainly data tracking devices.

And whilst many are sceptical of how the data is used, realistically everyone is positively affected by modern data collection. Even if we don’t realise it, data today is allowing us to make educated changes to our lifestyle, finances, social lives and health.

It seems odd that a widely available resource such as data is taken for granted everyday, and isn’t used effectively to do the really important things more regularly – especially when it comes to saving lives and preventing life threatening illnesses.

Sadly, the global annual number of people dying from occupational respiratory illnesses is estimated at over 500,000. The critical question remains: are we using the data at our disposal to positively impact workplace health and safety? Probably not…

Firstly, we need to understand that data is critical, and a lack of its use is a problem. Real-time dust monitoring has long since been an expensive, complicated “black art” unavailable to the masses. Whilst monitoring isn’t a solution in itself, it’s pivotal to making the right decisions to ultimately save lives and understand where the risk really lies.

Gravimetric or “dust deposit” gauges have long been an industry standard, and a legislative medium for measuring harmful dust exposure; but they only give ‘one side of the story’ and even then a partial story at best. When it comes to saving lives, time is of the essence. Even more so early detection and real-time alarming typically results in prompt action.

This gravimetric data is not to be dismissed and is important, but let’s face it with global numbers of over 500,000 people still dying every year, it’s not enough. So how do we critically challenge the status quo?

Now imagine taking this combined average data over a time frame, and combining it with accurate, real-time, personal dust monitoring. Imagine the changes you could make to process, controls, procedures and culture by seeing when and how the exposure is caused, where it was unacceptably high and, maybe, even warning people in real-time who unknowingly enter into the dangerous zone of this invisible killer.

If a smoke alarm goes off, you leave the building regardless of whether you see the fire. Why shouldn’t we apply the same theory, conscious response and swift action to slow and painful killers such as respirable dust?

Exposure is commonly expected in mining or engineered stone industries, however many more are unsuspectingly exposed in construction, demolition, quarrying, manufacturing, and more generally those in support functions in nearby offices and facilities within these industries and even people regularly using non-dust controlled roads.

The sad thing is, if the danger isn’t obvious (and dangerous levels of dust often aren’t as the most dangerous particles are usually the invisible ones), it’s too easy to ignore until the damage is done.

With real-time data, it’s easy to make decisions on measures that need to be taken to understand personal exposure levels and even have real time exposure warnings. Trolex is giving the power back to the people, companies and regulators to make informed decisions about protecting themselves and each other in the interest of saving lives.

If this drives changes in monitoring requirements, engineering controls such as dust suppression or RPE regulations can only benefit people and the families of those people who are currently exposed, all whilst minimising the risk of future exposure, and building precedence for the application of effective dust control measures in the hierarchy of control.

Here’s another thing: as a business or a responsible person, real-time monitoring and control is not only affordable and simple, but also accessible to everyone.

So, the question is, can you afford to not understand the problem?

Our aim is to give people the information, to save lives and increase awareness, and if you want to know more about our real-time fixed, portable or personal dust monitors (AIR XD Dust Monitor, XD ONE Portable Dust Monitor or XD1+ Personal Dust Monitor) then get in touch today.

As strange as this question may sound…have you ever taken a moment to sit down and think about dust? Really think about it? Think about what it actually is, where it comes from, why it exists, and the impact it might have on our lives?

Probably not. And why would anyone? It’s just ‘there’ after all, hanging around, doing its thing. A staple accompaniment to life, only momentarily revealed in a shaft of sunlight or a sneeze, or lying on an expensive piece of machinery waiting to be…dusted.

And while we’re all aware that exposure to dust or particulates can impact health, isn’t it the case that because dust is so small, so ephemeral, and so everywhere, questions of what it actually is, and what it really does, tend to get swept under the carpet?

So here’s a chance to take a closer look at what we’re dealing with when we refer to ‘dust’ and reflect on the significant health implications of exposure to something largely unseen that threatens the lives of many thousands of workers, in many hundreds of different industries around the world.

Dust, or for the purposes of this explanation, particulate matter, is, defined by Greenfacts as, ‘the sum of all solid and liquid particles suspended in air.’

A complex range of components including organic and inorganic particles, such as pollen, soot, smoke, and liquid droplets, particulates can vary greatly in size (from coarse, to fine, to ultrafine), in composition, and in origin.

Many types of particulate are considered hazardous.

Putting dust in the home (composed of about 20–50% dead skin) to one side, about a third of the particulates that make up air pollution are created by vehicles, exhaust fumes, and particles from tyres and brakes.

These coarse particles are made up of broken-up larger particles, with a size ranging from 2.5 to 10 µm (a micron is a millionth of a meter). They are also released by agricultural processes, mining, and burning fossil fuels, as well as naturally through pollen, mould spores, and plants and insects.

While industry and the burning of fossil fuels can produce particles from the release of non-combustible materials, other fine sub-micron particles are produced by the condensation of vapourised materials and atmospheric reactions of sulphur oxides and nitrogen oxides initially released as gases.

These fine particulates between 0.1 µm to 2.5 µm, make up most of the airborne particulate mass and represent the main danger to people living or working in a polluted environment.

Ultra fine particles which are smaller than 0.1 µm make up only a few percent of total particulate mass, though they represent over 90% of the number of particles. They’re largely formed from gases that will often end up coagulating to form a larger particulate.

Worldwide, the main cause of air pollution is coal burning, with dirty air killing more people than smoking, car crashes and HIV/Aids. It also shortens billions of people’s lives by up to six years according to a new report.

The climate crisis too, largely a product of burning fossil fuels, is now making a significant contribution to air pollution through wildfires.

But that doesn’t mean the dangers of inhaling dangerous particulates are limited to smoggy city life or pollution blown cross country from burning forests.

At Trolex, our mission is focused on protecting the millions of people exposed to dangerous workplace dust, mist, fumes, vapour or gas – particulate threats that cover the full spectrum of particulate size.

As we wrote in our The importance of reading the room ebook:

‘Potentially lethal dust is everywhere – from construction dust, to the fibreglass/Glass Reinforced Plastics (GRP) used in loft insulation, and 3D printing that fuses layers and layers of extremely fine dust to create the final shape.

There’s coffee dust, soldering fumes (20% of people soldering or working around solder develop asthma), carbon fibre and plaster related lime, sulphate hemihydrates, silica, and mica dust that leads to asthma, COPD, chronic bronchitis, and emphysema.

There’s cement dust, plus the ubiquitous Amorphous Silica used in car tires, agri chemicals and animal feed, in toothpaste and cosmetics, paint, insulation materials, adhesives, coatings, and printer ink.

There’s biomass dust, dust created by waste disposal and recycling, sawmill wood dust, dust in nail bars, chiropodists, and podiatry clinics, tool sharpening dust and MDF dust particles coated in formaldehyde.’

There’s a huge amount that can be done to protect people from the dangers of inhaling dangerous particulates.

On a national level, governments can actually back up the rhetoric with action, instead of just paying lip service to environmental protection. China’s “war against pollution” that started in 2013 has already, supposedly, reduced levels of fossil fuel pollution by 29%.

But clearly much more needs to be done by politicians and business leaders to transition industry to greener, less damaging energy and manufacturing production. To promote production methods which will reduce the creation of hazardous dust.

Which is why we’re working so hard to both raise awareness of the problem and to put our Trolex AIR XD Dust Monitor, XD ONE Portable Dust Monitor, XD1+ Personal Dust Monitor andAIR XS Silica Monitor in the hands of people on the frontline who we can help protect.

With 12,000 UK, and half a million workers around the world dying every year from preventable diseases directly related to dust and particulate inhalation, our mission is as simple as it’s singularly focused, as it’s important.

It’s this: To educate the world’s construction, mining, tunnelling, heavy and manufacturing industries on the dust and particulate dangers their workers face. Then to make clear the smart, simple, cost effective ways our XD One and other duct monitoring technology can help them protect them. And ultimately…

For every worker exposed to dangerous particulates to have wearable personal dust monitoring equipment by 2031.

Get in touch today to speak to one of our experts about how real-time dust monitoring can help improve your safety processes and keep your workers safe from harmful respirable dusts.

When it comes to occupational health and safety, new real-time dust monitoring such as the XD ONE Portable Dust Monitor can help to make decisions for the hierarchy of controls.

In this e-book we explain how the arrival of affordable, real-time monitoring, and both wearable and portable dust monitoring technologies promote this new awareness of the dangers of dust in a far broader range of working environments.

Employers and the health and safety community are now shifting their attention. Where they’ve traditionally focused on safety, they now look at the major impacts on long-term health associated with working in hazardous environments.

There’s also an increasing awareness of the range of industries that can present long-term health hazards through the inhalation of dangerous dust particles, from traditional industrial environments to commercial activities.

The HSE are reporting an estimated 1.4 million people in the UK report ‘lung or breathing problems that were caused or made worse by work’ – and whilst it’s great that people are starting to pay more attention to this issue, there’s plenty of room for improvement.

Whilst financial costs of lung diseases effect both businesses and individuals, respiratory diseases are more than just an economic drain. It’s a personal tragedy, and there are a whole raft of occupations and jobs where people are exposed to dangerous dust across the world.

However, through the hierarchy of controls, businesses can determine the most effective solutions in order to keep workers protected from dangerous dust exposure.

Knowing that dangerous dust exists, knowing its effects are potentially lethal, and knowing that the damage it causes is preventable, only takes you so far. Knowing how to prevent that harm is what matters, and this is how the hierarchy of controls can help businesses become more efficient, by understanding how effective each method is in benefitting the workforce.

Fortunately, new accurate, real-time, fixed, wearable and portable dust and silica monitoring sensors are leading the detection charge across every use case. By precisely reading the real-time dust load in any given environment, and the enemy now ‘visible’, businesses can begin to apply the hierarchy of controls in a far more meaningful way.

An independent UK agency responsible for the encouragement, regulation and enforcement of workplace health, safety and welfare, and for research into occupational risks in Great Britain, carried out a series of tests on three XD One Portable Dust Monitor units.

They compared them to the following dust monitors: Casella CEL-712 Microdust Pro, a Thermo Scientific MIE Personal DataRam (pDR) 1500, a TSI SidePak AM510.

The key elements of the testing were as follows:

The results from the independent testing demonstrated that the XD ONE performs better than other personal dust monitors on the market. There were five critical messages from the testing as outlined below:

Working with distributors and partners overseas is how we gain exclusive access to the businesses that need our products to save the lives of their employees.

We value our close partners as much as our own employees and have good relationships that last way beyond the business transaction. This includes trusting our partners to demonstrate our new technology to their customers, in mutual understanding, so our partners and their customers can get ‘up close and personal’ to our XD ONE Portable Dust Monitor and can try it out for themselves in a real-life environment.

Our Belgium, Netherlands and Luxemburg (BeNeLux) distributor, BASystemen, ordered six XD ONE demo units to give to their customers to trial. They landed a few days ago, and their directors are already behind our campaign to get these monitors into the hands of every worker who needs one, and to start saving lives straight away.

Khoa Nguyen is a keen advocate of field trails, and comments ‘we love feedback!’ He intends to lend them out to his customers so they can ‘try out all functionalities’.

The dust monitors themselves have been met with great praise and Khoa says, ‘We truly believe that the XD ONE Portable Dust Monitor is a nice solution to the market needs for a portable dust monitor, which is simple to use, reliable and cost effective’. He adds, “…size is great, weight is perfect and very easy to use.”

Khoa is happy with our partnership, and concludes by saying, “Response is quick and partner conditions are good so both parties benefit long term” and suggests that as a company, BASystemen can “definitely learn from this.”

If you’re a distributor and would like to request demo units of the XD ONE Portable Dust Monitor, please get in touch today.

Did you hear about the plane crash that killed everyone on board? Your answer likely depends on where you live.

According to researchers at the University of Oxford: ‘English Wikipedia readers were much more likely to read about North American and European crashes, and Spanish Wikipedia readers were more likely to read about Latin American crashes.

Page views on English and Spanish Wikipedia for North American and Latin American aircraft crashes, respectively, were each about 50 times greater than for African crashes.’

These events are tragic, to be sure, but the deaths from these situations are more generally heard about than others, such as from dust inhalation – despite technology and processes available to help prevent them.

It also depends on when the crash happened, with Royal Society Open Science discovering that irrespective of the crash location and body count, ‘on both English and Spanish Wikipedia, page views dropped in half between three to 10 days after the event’. The decay of novelty as we lose interest in things when they stop being new.

And then there’s how much capacity you have left to care, the concept scholars refer to as the ‘finite pool of worry’.

‘Because people have a limited capacity for how many issues they can worry about at once, as worry increases about one type of risk, concern about other risks may lessen.’ says The Centre for Research on Environmental Decisions.

Proximity. Timing. The competition with other concerns for a limited capacity to impact emotions. It’s a complicated old business. Disaster, its impact, its legacy and even the ways we look at – or away – from it. That’s only talking about sudden disastrous events; the plane crash, typhoon, earthquake, and other similar events.

What about the disaster that inexorably unfolds? The slow-motion cumulative disaster. Disaster that – over time – takes far more lives than the one off tragedies? Or even a succession of one-off tragedies?

What about:

As we’ve seen, it’s human nature to focus on more recent, local, high-profile events. Discreet, distinct, storylines.

However, don’t the disasters we overlook – the slower moving, less attention-grabbing tragedies that play out day after day – deserve our attention too?

The problem of particulate and dust inhalation is widely ignored, so too is the priority in finding viable solutions.

This is why we do what we do at Trolex, and why we’ve set ourselves the challenge of reducing the risk and impact dust inhalation can have on workers around the world who are rarely spoken about.

This is done through the development of technology like the AIR XD Dust Monitor, XD ONE Portable Dust Monitor, XD1+ Personal Dust Monitor and AIR XS Silica Monitor alongside supporting software, to deliver data in realtime and make sure every worker knows the state of air around them.

We haven’t stopped there, however. Our engineers are constantly asking “what can we do so that, in 10 years time, every worker in the world exposed to dangerous particulates is wearing personal dust monitoring?”

This is easier said than done, of course, but it’s a challenge we’re committed to undertaking and beating. As well as setting ourselves the task of overcoming the engineering challenge, we’re having to face those natural ‘hidden in plain sight’ biases discussed above.

We’ve privately funded each project every step of the way – from research and development, to manufacturing and distribution. Every penny.

Not that we mind. In fact, we’re proud to have independently conceived and created our range of real-time dust monitoring products: innovative dust monitoring technology that’s now the envy of the industry.

These products are perfectly capable of helping us meet our 10-year challenge, and in the process save many thousands of lives.

Set against the backdrop of Covid-19 and the billions and billions of pounds spent to combat it, the macabre irony hasn’t been lost on us, that worldwide more people have died inhaling dangerous particulates in the last five years than they have from Covid 19.

Unnecessary deaths that for only a couple of million pounds backing, our technology could still go faster and further in preventing.

Maybe we should call for a lockdown?

We work with businesses around the world to improve the safety of hazardous work environments and give workers a better chance at reducing the risks of dust inhalation. The long term effects can be severe and, while it might not be as obvious or attention grabbing as other tragedies, we’re committed to doing what we can to help those at risk.

If you’d like to know more about our dust monitoring systems and how they can help your worksite, get in touch with our team of experts today.