With an estimated 1 million people dying globally from the inhalation of dust in occupational environments every year, now is the time to protect your workers. Personal and portable dust monitoring provides a simple solution for all workers at risk of dangerous dusk regardless of their application, processes or industry.

We’re continuously innovating our real-time dust monitoring technology to give you access to the information to effect change and keep your workers safe from hazardous respirable dusts. Which is why we have developed the XD1+ Personal Dust Monitor and the XD ONE Portable Dust Monitor.

Both products provide a unique approach to personal, handheld, portable dust monitoring. It’s dust monitoring that doesn’t get in the way, that’s small and versatile enough to give you the freedom to do your job whilst making zero compromise on accuracy and reliability, remaining easy to use, simple to maintain and cost effective.

With an estimated 1 million people dying globally from the inhalation of dust in occupational environments every year, now is the time to protect your workers. Real-time dust and silica monitoring provides instant alarms and alerts for all workers at risk of dangerous dusk regardless of their application, processes or industry.

We’re continuously innovating real-time dust monitoring technology to give you access to the information to effect change and keep your workers safe from hazardous respirable dusts. With a range of dust and silica monitoring options, we’re here to help you protect your workers.

Whether that’s heavy-duty area monitoring for high dust loading environments, personal dust monitoring for individual monitoring needs, or silica monitoring for working environments with high respirable crystalline silica (RCS) content, such as stonemasonry, tunnelling or quarrying.

Real-time monitoring offers solutions to us in our everyday lives. Whether it’s the real-time alerts that tells you that you’re at risk or in danger, or the subsequent data which provides you accurate information on what you’re monitoring, real-time monitoring has become an essential part of our lives.

But what about real-time monitoring when it comes to enhancing the workforce? You’d rely on real-time monitoring and alarms to tell you there’s a fire in your home, so why wouldn’t you rely on real-time monitoring to tell you if you were a risk as serious to your health at work? You’d rely on real-time data to tell you if you needed to track nutrition or health trends, so why wouldn’t you rely on essential data in real-time in the workplace?

Whether it’s for the health and safety of you and your colleagues, to better understand the processes and efficiency of the business, or just to help aid decisions, real-time monitoring can provide valuable data to workforces across a whole range of industries. Whether you are monitoring for hazardous substances like dust or silica, or monitoring for HAV, sound levels or proximity measures, real-time monitoring can enhance your workforce.

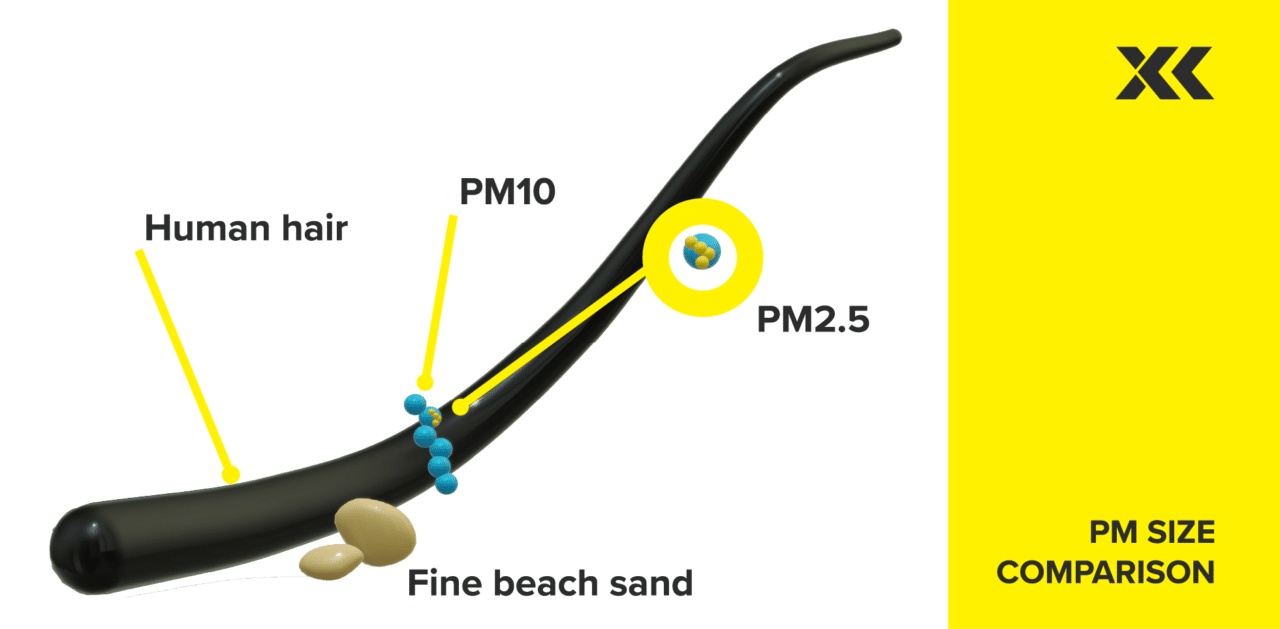

‘PM’ or particulate matter, also known as particle pollution is the term for a mixture of solid particles and liquid droplets found in the air.

It’s estimated that air pollution is linked to 43,000 deaths per year in the UK. Worldwide, at least 7 million people die each year from exposure to air pollution, with 91% of the worldwide population living in locations where the air quality exceeded the World Health Organisations (WHO) air pollution guidelines.

These guidelines state that that annual average concentrations of PM2.5 should not exceed 5 µg/m3 and PM10 should not exceed 15 µg/m3 (both for 24-hour periods). According to the WHO, ‘fine particulate matter at PM2.5 can penetrate through the lungs and further enter the body through the blood stream, affecting all major organs’. Exposure to dust at PM2.5 can cause serious disease to the respiratory system, such as lung cancer and COPD, and also can effect cardiovascular diseases, such as a stroke.

The image below demonstrates PM2.5 and PM10 size in comparison to a single human hair and a grain of sand.

The Department for Environment Food & Rural Affairs (DEFRA), the UK government ministerial department for environment protection, have also highlighted the severity of exposure to air pollution. This growing concern for the UK government estimated in 2010 that the cost of health impacts of air pollution was likely to exceed estimates of £8bn to £20bn.

Although between 2005 and 2022, the UK’s PM2.5 emissions decreased by 41%, emission levels have been relatively steady with small annual fluctuations in the last decade. Industrial combustion is a major source of PM emissions, as well as emissions from industrial production also playing a major part, which can be linked to heavy-dust industry where hazardous particulates can become airborne. Despite some reductions in PM emissions, the threat still very much remains.

A solution to this is real-time dust monitoring. Real-time particulate monitoring allows people in heavy dust loading environments, including industrial applications, to not only understand, but alert them instantaneously when they are exposed to dangerous levels of air pollution. For example, our AIR XD Dust Monitor can alert people in real-time when legislative levels of µg/m3 are breached, over a time-weighted average (TWA) 8-hour period, for both PM2.5 and PM10.

This technology not only offers a simple solution to individuals at high risk of exposure to air pollution by providing instant alerts, but also can help to prevent exposure in the future, as at-risk individuals can learn exactly when and where exposure to air pollution is highest and will likely occur. Thanks to real-time monitoring, both in the UK and Worldwide, we can reduce exposure to air pollution.

Working with distributors and partners overseas is how we gain exclusive access to the businesses that need our products to save the lives of their employees.

We value our close partners as much as our own employees and have good relationships that last way beyond the business transaction. This includes trusting our partners to demonstrate our new technology to their customers, in mutual understanding, so our partners and their customers can get ‘up close and personal’ to our XD ONE Portable Dust Monitor and can try it out for themselves in a real-life environment.

Our Belgium, Netherlands and Luxemburg (BeNeLux) distributor, BASystemen, ordered six XD ONE demo units to give to their customers to trial. They landed a few days ago, and their directors are already behind our campaign to get these monitors into the hands of every worker who needs one, and to start saving lives straight away.

Khoa Nguyen is a keen advocate of field trails, and comments ‘we love feedback!’ He intends to lend them out to his customers so they can ‘try out all functionalities’.

The dust monitors themselves have been met with great praise and Khoa says, ‘We truly believe that the XD ONE Portable Dust Monitor is a nice solution to the market needs for a portable dust monitor, which is simple to use, reliable and cost effective’. He adds, “…size is great, weight is perfect and very easy to use.”

Khoa is happy with our partnership, and concludes by saying, “Response is quick and partner conditions are good so both parties benefit long term” and suggests that as a company, BASystemen can “definitely learn from this.”

If you’re a distributor and would like to request demo units of the XD ONE Portable Dust Monitor, please get in touch today.

It’ll come as no great surprise: the more hassle something is, the less people want to do it. A simple fact, from technology, to sport, to entertainment, to business, the ‘more trouble than it’s worth’ factor relates to every aspect of life. There’s even a model that represents it. Fred Davis’ 1986 Technology Acceptance Model (TAM) designed to measure the adoption of new technology based on customer attitudes.

The time, the trouble and the expense of ‘high maintenance’ dust monitoring equipment goes a long way to explaining why it has never really been adopted to the scale that workers truly deserve.

Traditional dust monitoring equipment:

– Takes too much time to deploy

– Needs continual fiddly maintenance

– Costs too much money

– Is often too big, too heavy and too fragile

– Is too much hassle

Which is why we’ve worked so hard to develop, manufacture and distribute the Trolex XD ONE Portable Dust Monitor.

The new, easy-to-use, low maintenance, reliable and accurate personal dust monitor; more like a PPE product than a traditional high-maintenance dust detector or analyser.

Let’s take a look at the Trolex XD ONE Portable Dust Monitor, in particular its ease of use, deployment and maintenance, against the leading products already on the market.

Let’s see how they compare – or more realistically – how they don’t. Because, as you’ll see for yourself, the advantages of the XD ONE are so many and so significant that any genuine comparisons are few and far between.

How easy is the unit to wear, use, and get working?

Trolex XD ONE Portable Dust Monitor: Pick it up. Switch it on. Off you go…and go…and go.

Compared to:

TSI SidePak AM520/520i: Larger and 30% heavier than the XD ONE. Requires different impactors for different particulate sizes that need to be recalibrated as they’re swapped out. Fiddly tube clipping required.

SKC HAZ-DUST IV: Three-times heavier than the XD ONE at 1.4 kg and much larger. Base unit + tube + sampling head clipped near breathing zone with separate filter unit.

CASELLA APEX 2: Requires a clean environment and tweezers to handle the filter. Flow meter and calibration adapter kit not included and needs to be purchased separately.

Nanozen DustCount 9000: Base pump unit with impactors, tube to head unit with filter in cassette and sensor. The usual set-up with the usual problems. Don’t forget to remove the red cap before switching on or you’ll damage the unit!

TM DATA II: Much bigger and 20% heavier.

What kind of burden does the typical maintenance cycle put on the user?

Trolex XD ONE Portable Dust Monitor:

– Five seconds for automatic or on-demand self-testing

– 60 seconds of compliance every six months

– No return-to-base, complex set-up or calibration

– That really is it. PPE for the real world

Compared to:

TSI SidePak AM520/520i:

– Recommended annual return-to-base

– Impactor maintenance – eight-step process

– “Impactor should be cleaned prior to each use.” – TSI website

– Cyclone maintenance – complete disassembly and reassembly

– Separate filter unit required to perform daily calibration check

– Multiple monitors required to bump test in the field. It is very difficult to generate a known aerosol concentration for a ‘bump test’ in the field without very sophisticated equipment. With use of multiple SidePak Monitors running them side by side…if all instruments are within 20% of each other, they are all functioning properly’ TSI website

SKC HAZ-DUST IV:

– 81-page manual

– “Sensor optics to be checked every 48 hours when used in a 2-3 mg/m³ TWA environment and on a weekly or monthly basis in less contaminated environments” – eight-step cleaning process using a bespoke kit

– Flow rate must be checked every time a new gravimetric filter Is used – six-to-eight-step procedure

– Calibration every month as a minimum/when dropped – minimum 11-step procedure

– Annual third-party calibration required

– 19 accessories

CASELLA APEX 2:

– Annual return to base/or after 2,500 hours, whichever is sooner

– Loaded filter or battery voltage reductions affect air flow speed requiring variable flow to be monitored at all times. In-built pressure and temperature compensation, pulsation control, high back pressure and long battery life presented as great ‘features’ of their product when in fact they’re all only necessary because of the antiquated filter-based methodology used

– Inlet filter to be replaced every three months (more often in challenging environments) four-stage process

– Different filters are required for different applications and this needs to be worked out

Nanozen DustCount 9000:

– Recommended annual return to base

– Impactor has to be oiled and cleaned – fiddly with small pipettes of special oil and a three-minute wait before re-assembling and cleaning with a special alcohol substance

– New filters need to be inserted into the filter cartridge. A screwdriver, clean area and tweezers required

– Pump needs to be calibrated. Separate filter unit required to do this

TM DATA II:

– Special calibration kit required

– Measuring chamber cleaned with oil-free pressurised air or with soft dry brush

– Light trap covers can be screwed out so that dust particles can be blown out of the light trap

– Lenses in front of the diodes can be cleaned with Q-tip wetted in alcohol

– Internal calibration and zero-point adjustments should be carried out on regular intervals

– Maintenance and repair only by qualified personnel

The Trolex XD ONE Portable Dust Monitor – a device that’s so easy to use and maintain, so useful, that it’s more hassle to NOT use it.

And when you start to tot up the cost benefits of the XD ONE over its competition, it’s hard to know where to start.

– The time saved in setup

– The hours of maintenance saved

– The savings in extra disposable kit

– Improved site performance

– Lower worker absenteeism

– Recruitment cost savings

– Reduced legal and litigation costs

Perhaps the greatest benefit though is one that can’t be measured in monetary terms – the opportunity to prevent your workers from suffering avoidable, life changing disease, and premature death. Priceless.

There’s a well known sales mantra that goes: “People don’t buy the best – they buy products they can understand the fastest.”

The same principle applies to technology adoption.

People don’t buy the best – they buy products that are easiest to adopt.

The great thing here is that not only are Trolex products the easiest to adopt, they’re more accurate, far simpler to maintain and significantly cheaper to use than anything else in the market. The best.

So, when the question is:

‘How do we best encourage people to use dust monitoring equipment and to keep using it because it’s easy to deploy and easy to maintain?’

The answer is as simple as it’s effective.

The Trolex XD ONE Portable Dust Monitor.

If you’d like to find out how real-time dust monitoring can help improve your safety processes, get in touch today.

We’re living through an air pollution emergency. One that’s already claiming thousands of lives and costing billions of pounds. And that news shouldn’t come as a surprise.

We wrote in a recent blog, The threat from particulates: It gets worse about an American academic study: “Long-Term Exposure to Fine Particulate Matter, Residential Proximity to Major Roads and Measures of Brain Structure.”

The report clearly shows the risks that people living over extended periods near busy main roads face from fine dust that causes respiratory diseases, results in brain atrophy (brain shrinkage) and leads to an increased risk of stroke and other disease.

Another academic paper, ‘Air Pollution and Noncommunicable Diseases’ suggests that air pollution may be damaging ‘every organ in the body.’

Unfortunately there was nothing ‘academic’ about the consequences of particulate inhalation for nine year old Ella Kissi-Debrah, whose death in 2013 was caused by ‘acute respiratory failure, severe asthma and air pollution exposure’.

“The whole of Ella’s life was lived in close proximity to highly polluting roads. I have no difficulty in concluding that her personal exposure to nitrogen dioxide and PM was very high,” stated the coroner.

And the really sad thing about Ella and her family’s suffering?

Is that it’s far from unusual.

According to the World Health Organisation, air pollution is the “new tobacco”, killing 7 million people a year and harming billions more.

“No one, rich or poor, can escape air pollution. It is a silent public health emergency.” Dr Tedros Adhanom Ghebreyesus, the WHO’s director general.

More than nine in ten people breathe toxic air and 300 million live where toxic fumes are six times above international guidelines and the health impacts are profound – especially for children.

So what’s going on? How is it possible that so many people suffer so much through filthy, contaminated air?

A rush for profits? For progress? For economic advancement? A lack of technology? Insufficient knowledge? Clarity of thought? Understanding? Will? A short-termism that prioritised wealth over health?

In truth it’s all these factors and more. Reasons, more often excuses, that in the not so distant future people will look back at in horror. A situation where people simply won’t believe that things were allowed to get so bad and stay so bad for so long.

Thankfully, though belatedly, the weight of detailed research, visible interventions from the likes of WHO, an increasingly active green movement and high profile tragedies such as the death of Ella Kissi-Debrah are seeing attention at last turning to the issue of air pollution and how best to tackle it.

So much so that the language of particulates and respiratory health is even entering mainstream use. The government responded to Ella Kissi-Debrah’s death with, “We are delivering a £3.8 billion plan to clean up transport and tackle NO2 pollution, and going further in protecting communities from air pollution, particularly PM2.5 pollution, which we know is particularly harmful to people’s health.’

Which is great.

But while a public recognition of the issue and an ability to deploy the right words in addressing the issue is a positive sign, it’s the ability of governments and industry to actually do something about air pollution that really matters. Action that all of us will be judged on in the future.

Signs are mixed. For example, despite the UK Government’s recognition that we all need to be protected from toxic air, and despite pledging funds to fight that cause, it has so far voted against proposals to put WHO pollution limits into UK law, arguing that they’re ‘uneconomical.’

‘Were you part of the problem or part of the solution?’ we’ll all be asked in the not too distant future.

Which is why we do what we do here at Trolex – to be a very proud and purposeful part of the solution.

Enquire today about our new AIR XD Dust Monitor and XD ONE Portable Dust Monitor in our real-time dust monitoring range – accurate, simple to use, easy to maintain, real-time particulate detection technology that keeps people safe.

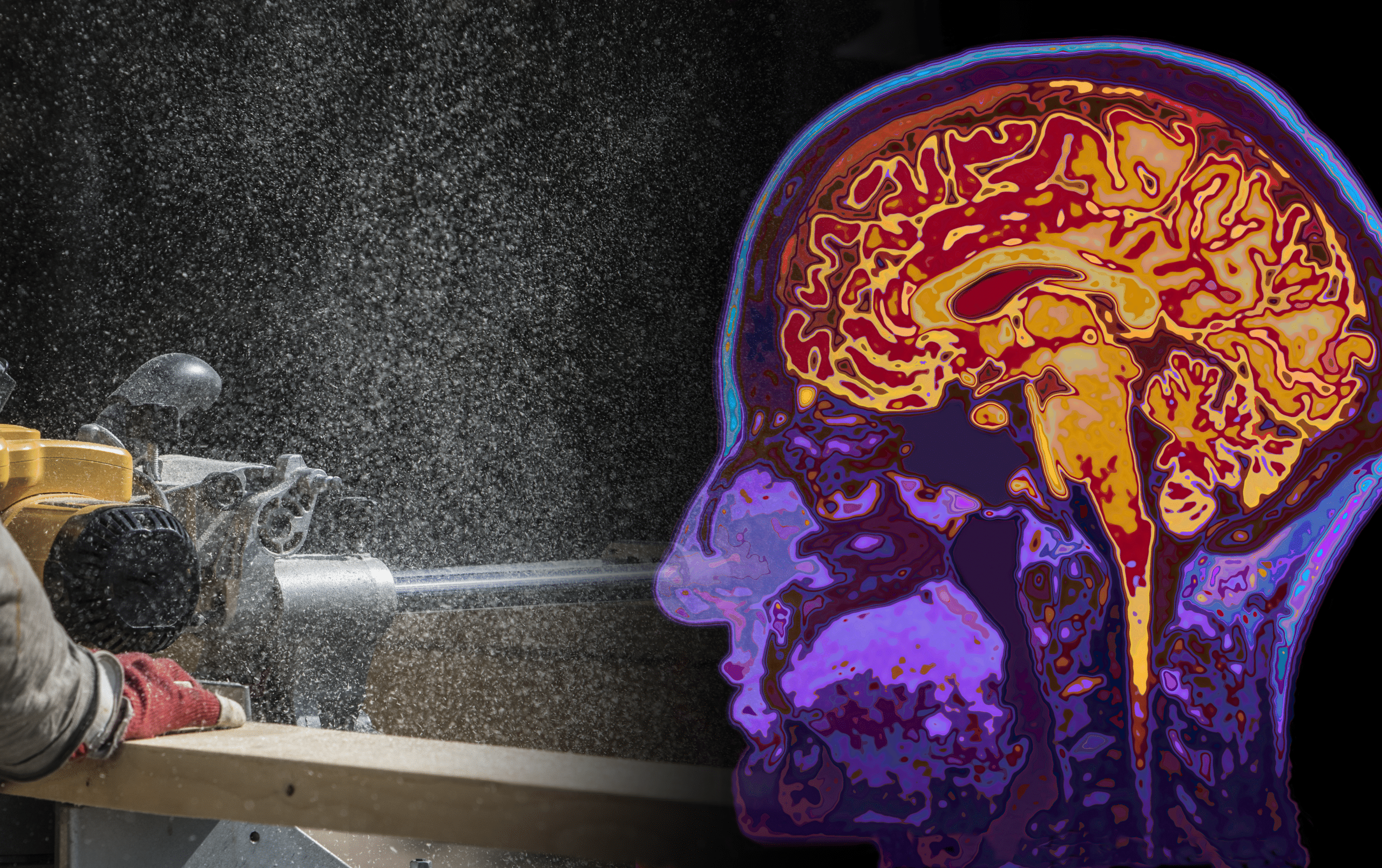

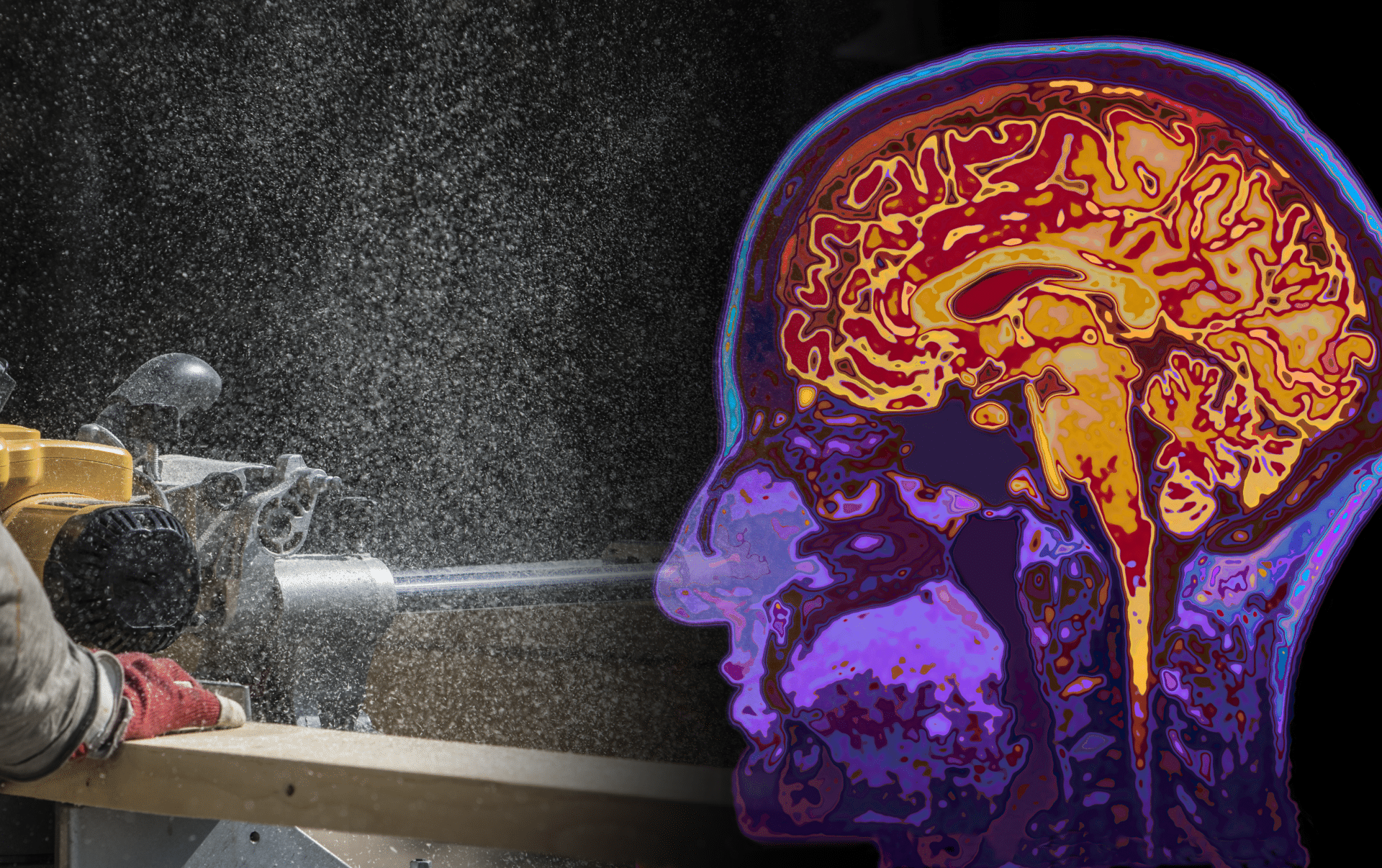

As if the known dangers of exposure to harmful respirable dusts weren’t bad enough, new research is showing that long-term exposure to ambient air pollution is associated with a far wider range of diseases and highlights the importance of particulate monitoring.

Not only are 1.4 million people in the UK reporting ‘lung or breathing problems that were caused or made worse by work,’ and 12,000 people dying every year due to occupational lung diseases, evidence is mounting to show that airborne pollution also causes dementia, strokes and skin cancer.

The study, conducted in the USA and first published in the journal Stroke is titled “Long-Term Exposure to Fine Particulate Matter, Residential Proximity to Major Roads and Measures of Brain Structure“.

Examining the brains of more than 900 people over 60 years old, it revealed that long-term exposure to fine dust causes both brain atrophy (brain shrinkage) and leads to an increased risk of stroke and other disease.

Not only is this news alarming for those who live near busy roads, it also draws attention to the added dangers faced by those working in conditions, and with materials, they may have previously thought safe.

For example, welders, who, despite now using supposedly less dangerous materials and working in spaces where local exhaust ventilation (LEV) is employed, seem to be vulnerable to a far wider range of illnesses than previously thought.

As the report highlighted, even limited exposure of fine dust particles can lead to the heightened risk of cerebrovascular disease and cognitive impairment.

Benjamin Howell on the Fabricator.com says, ‘at the nanolevel, invisible to the human eye, the concentration of particulate matter can pose a great risk to welders. Studies show that welding fume particulates are mostly smaller than 0.1 micrometer, which makes nearly all welding fume particles respirable. They can penetrate deep into the alveolate region of the lungs during inhalation and remain firmly fixed there.’

It’s not all bad news though.

By revealing far greater and far wider reaching dangers than previously acknowledged, the new research means the important issue of how best to protect people from damaging dusts is getting the attention it deserves.

The sheer weight of evidence amassing from the likes of The Journal of Cleaner Production, The British Medical Journal, and Harvard is forcing the hand of governments, regulatory bodies and employers. The necessary steps to protect not just their workers, but every one of us exposed to dangerous airborne pollutants, are being considered and taken. This includes controls, sensors and dust detectors, among other things.

What if a threat could be detected before it even became a threat? What if you could be alerted to the presence of even the smallest of damaging airborne dusts before they had the chance to damage health?

Leading H&S expert John Cairns says:

“The best thing is to detect the hazard before you’re exposed to the hazard. Before you’re exposed to the hazard or a high concentration. You can get the hell out of there, or with the way this new technology works you can set off ventilation systems to clear the area.

The whole ethos behind the Health and Safety Executive (HSE) is to reduce the risk to as low as is reasonably practicable. I think the XD ONE Portable Dust Monitor is adding to that – it’s enhancing the safety system.”

Real-time dust monitoring is an effective way at reducing the risk to workers in hazardous working environments. When combined with RPE, PPE and other equipment, the threats from dust and particle inhalation are reduced drastically. This has a big impact on worker health, morale and productivity.

Send us a message today to find out more about our work to help organisations like yours protect your people from the threat of damaging dust particles with sensors, dust detectors and systems tailored to your work environment.

As any responsible employer knows – a clear threat to the health and welfare of your staff demands a clear response.

In industries such as construction, mining, tunnelling and manufacturing, the obvious risks to health posed by clouds of workplace dust can be tackled in new and different ways. Some precautions and protections include:

With more awareness of the dangers of dust inhalation, these protections become more effective as they are applied more extensively across different scenarios and environments.

However, dust monitors and other other equipment are only part of the story.

More dangerous than the dust you can see, is the dust you can’t see.

Dust can reach beyond the frontline workers benefiting from protection to threaten support and ancillary staff nearby.

An unfortunate consequence of focusing efforts solely on frontline workers is there are other members of the team who aren’t monitored and protected. Plant and equipment operators working in enclosed cabins, for example, might assume they’re safe but, with microscopic airborne hazards so hard to detect, they’re still exposed to serious amounts of risk.

This is one of the main reasons for the introduction of a new international standard for a consistent approach to designing, testing, operating, and maintaining the air-quality systems of operator enclosures – ISO 23875.

A standard that recognises and responds to the extent of the dangers caused by dust right across a working environment.

It’s a move that’s been welcomed across the board, with the Australian Mining Safety Journal and Mining Review Africa writing, ‘the new standard is likely to place a greater emphasis on the air quality inside the cabin than previously addressed.’

A recent ISO workshop run by Jeff Moredock, Lead at the ISO Working Group, advertised that the new cabin air standard will ‘Improve operator alertness, create a safer work environment and increase productivity.’

Of course, the big question is how do you properly assess the air quality in your cabin? How can you enforce a new and improved standard if you’re not able to accurately record particulate levels in real time?

This makes the introduction of new, wearable or in-cab, real-time dust monitoring technology, such as the XD ONE Portable Dust Monitor, so timely.

The XD ONE is low cost, lightweight, easy to use, easy to maintain and 5 times more accurate than other devices. It continually measures every particle from as small as 0.38 to 40 μm. By issuing every operator an XD ONE, they’re constantly reading the air quality in their immediate environment and instantly alerted to any danger.

In the past, dust monitors were large, clunky pieces of technology that needed to be placed in an area you expected to be hazardous. This was time consuming and took multiple workers to place, set-up and maintain and was inaccurate and often not in real time.

As this equipment has developed, it can now be worn by workers to monitor the dust particles in the space directly around their airways.

The XD ONE Portable Dust Monitor also delivers results in real-time, making it an important part of any safety system or process. Dust can be released at any point and isn’t always noticeable. It can also travel long distances on very slight air currents, so the more warning employees have, the better they can react.

With new regulations pushing for better safety measures and standards in hazardous workplaces and environments, you need to stay on top of everything. Your workers will also benefit, and this keeps them working for longer.

Get in touch today for more details on how the XD ONE Portable Dust Monitor can help you align with ISO Standard 23875 as well as protect workers across your whole site from the danger of microscopic airborne dust.