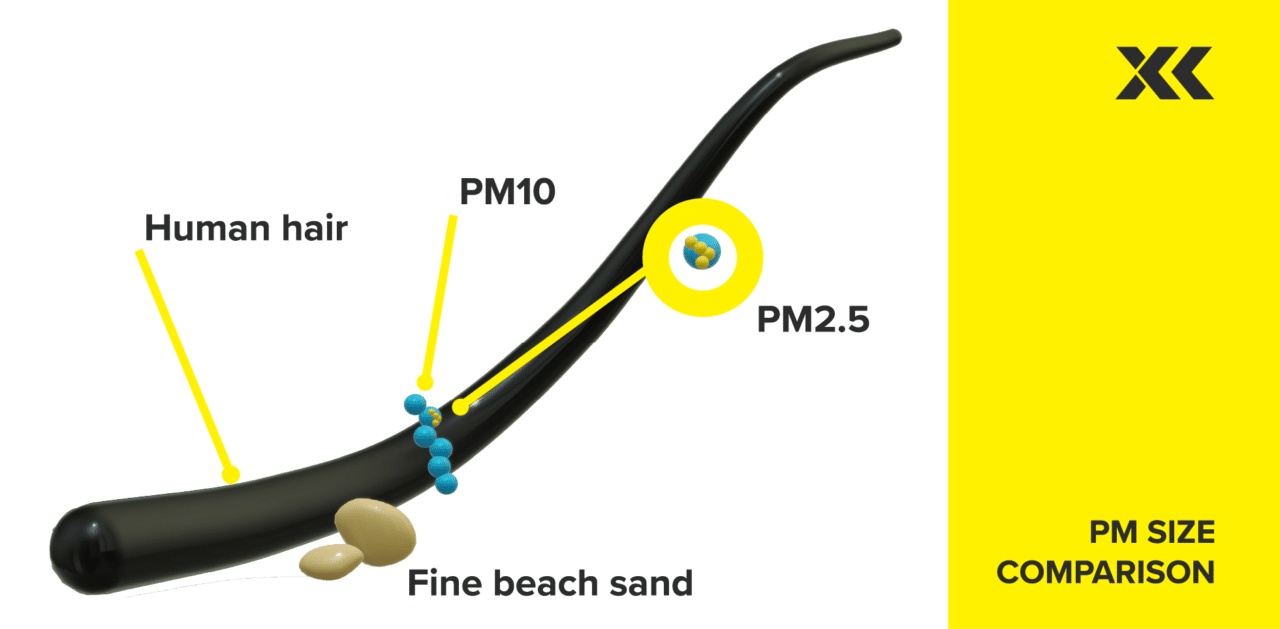

‘PM’ or particulate matter, also known as particle pollution is the term for a mixture of solid particles and liquid droplets found in the air.

It’s estimated that air pollution is linked to 43,000 deaths per year in the UK. Worldwide, at least 7 million people die each year from exposure to air pollution, with 91% of the worldwide population living in locations where the air quality exceeded the World Health Organisations (WHO) air pollution guidelines.

These guidelines state that that annual average concentrations of PM2.5 should not exceed 5 µg/m3 and PM10 should not exceed 15 µg/m3 (both for 24-hour periods). According to the WHO, ‘fine particulate matter at PM2.5 can penetrate through the lungs and further enter the body through the blood stream, affecting all major organs’. Exposure to dust at PM2.5 can cause serious disease to the respiratory system, such as lung cancer and COPD, and also can effect cardiovascular diseases, such as a stroke.

The image below demonstrates PM2.5 and PM10 size in comparison to a single human hair and a grain of sand.

The Department for Environment Food & Rural Affairs (DEFRA), the UK government ministerial department for environment protection, have also highlighted the severity of exposure to air pollution. This growing concern for the UK government estimated in 2010 that the cost of health impacts of air pollution was likely to exceed estimates of £8bn to £20bn.

Although between 2005 and 2022, the UK’s PM2.5 emissions decreased by 41%, emission levels have been relatively steady with small annual fluctuations in the last decade. Industrial combustion is a major source of PM emissions, as well as emissions from industrial production also playing a major part, which can be linked to heavy-dust industry where hazardous particulates can become airborne. Despite some reductions in PM emissions, the threat still very much remains.

A solution to this is real-time dust monitoring. Real-time particulate monitoring allows people in heavy dust loading environments, including industrial applications, to not only understand, but alert them instantaneously when they are exposed to dangerous levels of air pollution. For example, our AIR XD Dust Monitor can alert people in real-time when legislative levels of µg/m3 are breached, over a time-weighted average (TWA) 8-hour period, for both PM2.5 and PM10.

This technology not only offers a simple solution to individuals at high risk of exposure to air pollution by providing instant alerts, but also can help to prevent exposure in the future, as at-risk individuals can learn exactly when and where exposure to air pollution is highest and will likely occur. Thanks to real-time monitoring, both in the UK and Worldwide, we can reduce exposure to air pollution.

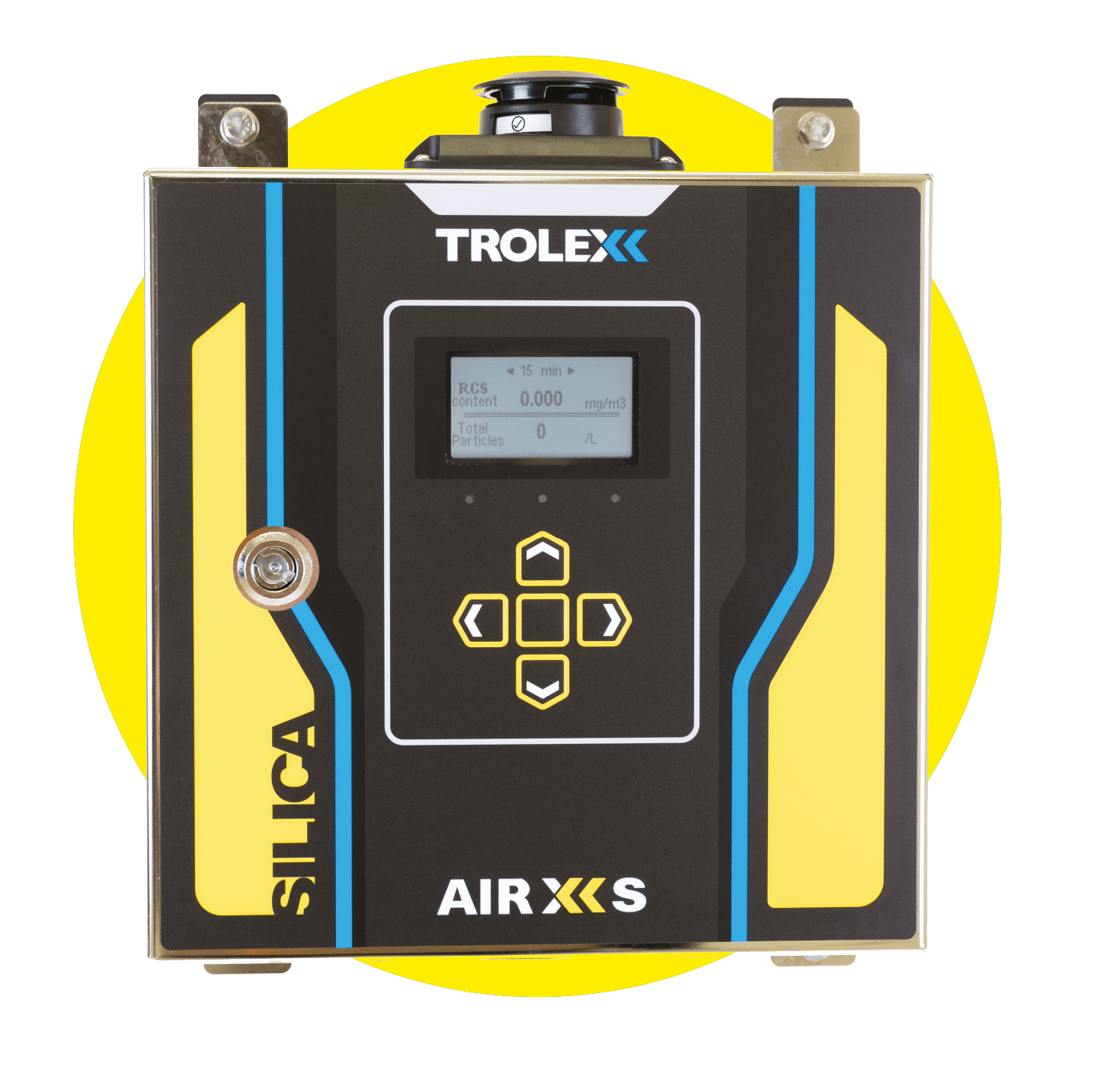

The AIR XS Silica Monitor leverages cutting-edge Optical Refraction Technology (ORT) to enhance workplace safety by providing real-time monitoring of respirable crystalline silica (RCS). Unlike traditional particle monitors, AIR XS distinguishes and measures RCS content, enabling immediate detection and response to harmful silica dust levels. This technology is crucial in combating occupational lung diseases such as silicosis, which affects millions of workers globally.

Current monitoring methods, like gravimetric sampling, are time-consuming and often deliver results too late to prevent exposure. In contrast, real-time silica monitoring offers immediate data, significantly reducing the risk of occupational silicosis by enabling prompt action to mitigate hazardous conditions. The importance of such real-time data is highlighted by cases like Joanna McNeill’s, who developed silicosis at the age of just 36. Her story, like many others underscores the necessity for continuous monitoring to protect workers from the threat of silicosis, regardless of their occupational environment.

Our real-time RCS monitor, AIR XS provides a real-time solution to this threat. Workers are not only alarmed and alerted when silica levels exceed legislative limits but can work to best practices by implementing AIR XS with the Hierarchy of Controls, supporting proactive measures to eliminate or minimise exposure to RCS. This move to real-time monitoring as a solution to the threat of silicosis has also been noticed by governing bodies, like the All-Party Parliamentary Group on Respiratory Health.

To learn more about how this real-time solution not only enhances worker safety but also streamlines business operations, click the link below to read the case study in full.

New test findings released, confirm the efficacy of a world-first real-time monitor for silica dust, which represents a revolution in the protection for workers exposed to respirable crystalline silica (RCS) dust.

As a leading workplace safety technology company, we have developed the AIR XS Silica Monitor, designed to protect workers against lung diseases such as silicosis by providing real-time readings of levels of crystalline silica in the air.

We have recently commissioned a leading occupational hygiene and laboratory testing organisation to conduct independent testing of the AIR XS. The results show the AIR XS repeatedly provided consistent, accurate, real-time data throughout an eight-hour testing period.

The testing demonstrates that AIR XS can improve worker safety by providing instant information to businesses and workers exposed to RCS, instead of having to wait up to four weeks to know their level of exposure to this killer dust, which is the current industry standard.

While the Australian Government recently implemented a ban on engineered stone, commencing 1 July 2024, the process most synonymous with creating silica dust, Group CEO Glyn Pierce-Jones said this ban alone would not solve the current health crisis caused by RCS.

“Silica dust is found in most building materials, so while banning engineered stone is a positive step, it’s not a holistic solution. The real issue facing the industry is the current archaic methods of testing for silica dust and the delay it causes in creating the safest possible workplace.”

The AIR XS is already being used in Australia to monitor RCS levels in many industrial locations.

Silica occurs naturally in soil, sand and granite; however, it is almost harmless in that state. Once those materials have been disturbed through construction or mining, silica dust is generated and can be inhaled into the lungs. This dust can cause silicosis, and other types of lung diseases and cancer, which are often irreversible and progressive.

Recent research from The Lung Foundation showed an estimated 600,000 Australian workers and between 40-50 million workers worldwide are exposed to silica dust across a wide range of industries including quarrying, construction, tunnelling, mining and many manufacturing processes.

The current approach to test for RCS is gravimetric sampling, the process requires collection, processing, and laboratory analysis of the sample, which is both time-consuming and costly for businesses. Direct-reading instruments offer businesses the ability to monitor employee safety on sites in real-time, eliminating the delays of weeks typically associated with potential RCS exposure.

Mr Pierce-Jones emphasised the urgent need for enhanced safety measures for anyone who may be in contact with silica.

“The current testing methodology for RCS only allows users to take an average reading over an eight-hour period and typically takes up to four weeks to produce a result,” Mr Pierce-Jones said.

“Our AIR XS Silica Monitor was designed to provide an accurate reading with immediate results, letting workers know when their health is in danger and allowing employers to respond in the most efficient manner.”

“These latest test results are another indicator of what we already knew at Trolex – that the AIR XS could be part of a desperately needed solution to an urgent health crisis.”

It’s estimated that over 40 million people worldwide are exposed to silica dust in the workplace. Respirable crystalline silica (RCS) contributes to one of the leading causes of death in the workplace, alongside other lung related illnesses. Due to this some of the industry’s most influential countries worldwide are making significant changes to regulations regarding silica exposure in the workplace.

In December 2023, Australia became the first country in the world to ban engineered stone due to rising cases of silicosis. From 1st July 2024, all use of engineered stone in Australia will be prohibited to protect workers from exposure to RCS in the workplace. Engineered stone is a manufactured material made from combining quartz or granite aggregates with resins and pigment and is a common material used in stone bench tops, often found in kitchens and bathrooms. It’s production often results in airborne RCS, leading to significant health risks to those working with it.

With reports that over half a million Australians are exposed to fine silica dust through stonemasonry and construction, figures suggest 103,000 of these workers are likely to be diagnosed with silicosis. The production and manufacturing of stone bench tops is a significant contributor to these statistics. The ban on engineered stone across the entirety of Australia is a step in the right direction to reduce the number of workers exposed to RCS and silicosis diagnosis in the future.

This ruling in Australia looks to have a set a precedent in influencing other countries to do the same. In May 2024, the first cases of silicosis linked to artificial stone countertops in the UK were reported, leading to calls for the material to be banned.

An estimated 600,000 workers are exposed to silica in the UK each year, and in Europe as a whole, 81% of those exposed are employed in construction or in manufacturing products used in the industry. After Australia became the first country worldwide to ban engineered stone in December 2023, UK kitchen company Herringbone announced they would also ban the sale of high-silica quartz worktop due to the risks posed to stonemasons.

Since speaking with their stonemasons about the risk of high quartz in engineered stone, Herringbone made the decision to become the first company in the UK to phase out the sale and production of engineered stone, as well as creating a petition to have the product completely banned in the UK, like in Australia.

In the US, the Biden administration has agreed to limit workers exposure to silica dust in mining, particularly when drilling for coal, ore and completing other mining operations. In April 2024, a ruling was announced to reduce the allowable silica dust levels in mining operations to 50 micrograms per cubic meter, with an action level at 25 micrograms, for an eight-hour workday.

The ruling will also update any respiratory protection standards for mining workers and in addition to silica dust, will also apply to diesel particulate matter and asbestos. The hope is that this will begin to reduce an estimated 1,067 deaths and 3,746 silica related illnesses in mining industries in the US and begin to make mining safer from the risk of RCS for the 55,000 American coal miners across the nation. The rule will come into action one year after its publication in April 2024.

With significant action being taken across major industries worldwide as of mid-2024 and onwards, protection for workers against respirable crystalline silica is becoming more of a high priority in workplaces. With banning of products known to produce dangerous levels of RCS, and with rule changes to limit exposure, workers short- and long-term lung health is becoming better protected than ever.

Our AIR XS Silica Monitor, an innovative real-time respirable silica (RCS) monitoring device, has been deployed at a major railway operations project to monitor the levels of RCS which workers may be exposed to.

The Central Rail Systems Alliance (CRSA), an alliance between Network Rail, Balfour Beatty, AtkinsRéalis and TSO have been using an AIR XS unit to monitor the levels of RCS released when damaged rail tracks are replaced; when rail track is damaged or needs replacing, the ballast surrounding the track is disturbed and can release RCS. The AIR XS unit was supplied by our UK partners Sunbelt UK & Ireland.

The challenge faced by CRSA was to measure the level of RCS and accompanying dust being released into the atmosphere during the unearthing process of 425m rail and ascertain the level of risk associated for those working in the immediate and surrounding environments. The AIR XS unit was manoeuvred around the site in-line with project progress, so that working scenarios can be accurately represented in the data set.

Upon conclusion of the project, Madeline Dunn, the Health and Safety Advisor for CRSA praised the monitoring and recording capabilities of the AIR XS, saying “We have completed trials prior, however this is the only unit where it is measuring silica and not just general dust levels. We gained the knowledge that the exposure levels were actually higher than we anticipated with even low-level ballast disturbance.”

Thanks to the team at Sunbelt Rentals UK & Ireland for the in-depth case study which you can read in full here.

Launched in 2022, the AIR XS Silica Monitor isn’t like other silica monitors on the market. If you’ve been in the Health and Safety space, it’s likely you’ll know about Optical Particle Counter (OPC), also known as “light-scattering”; but our patented AIR XS isn’t just another OPC.

Unlike traditional Optical Particle Counters (OPCs) that rely on light scattering and interruptions to deduce particle size and quantity, the patented Optical Refraction Technology (ORT) used in the AIR XS shines a laser through each particle, capturing its refraction on multiple sensors.

In our blog below, we reference Pink Floyd’s 1973 album Dark Side of the Moon to explain one way to how ORT works. It’s not exact by any means but the refraction of the light coming out of the prism shows an example of how light refracts, similar to a crystalline particle.

The effects of silicosis in the stone industry is not an unknown issue.

But to what extent are stone workers aware of this issue? Are the specific causes of silicosis in the stone industry common knowledge?

A scientific report from nature.com highlights the difference between engineered stone and natural stone, in relation to their silica content, shedding some light on where the cause of silicosis could lie in the stone industry.

Silicosis is one of the most dangerous respirable lung diseases in the workplace, especially when exposure to harmful silica dust is a common occurrence, such as in the stone industry.

It is estimated that globally, 40 to 50 million workers are exposed to silica dust in the workplace.

The Natural Stone Institute guide to awareness and prevention of silicosis determines that exposure to respirable crystalline silica (RCS), specifically in the stone industry comes from cutting or grinding materials, most commonly which contain quartz, is composed of silica dust.

The purpose of the study from nature.com was to see, in relation to RCS, what the most threatening scenario was for worker’s health, in real time, when working with different compositions of stone.

In the study, 12 engineered stones were assessed against three natural stones – white marble, white granites and black granites. By dry-cutting all stones, silica dust was captured in a closed environment and subjected to various assays to determine both chemical and physical properties.

The 12 engineered stones’ silica content varied from one another, and the total RCS content made up of quartz and cristobalite ranged from 70.4% to 90.9%. By comparison, the natural stone’s silica content ranged from 3.5% to 30.1%, marking a clear difference.

As well as this, the dry-cutting of engineered stone generated finer RCS particles with one engineered stone having an average size of as little as 190 nanometres, meaning it could reach deeper in the lungs, in turn causing more damage. Contrastingly, the smallest average particle size of the natural stone was black granite, with an average size of 503 nanometres.

The results of this study concluded that silica dust emissions from engineered stones had a much higher concentration of quartz and cristobalite, therefore having a higher silica content and subsequently more damaging impact on respiratory health.

Ultimately, the report concluded that the higher the silica content of the stone, as well as the smaller size of RCS particles, the more dangerous it is to respirable health.

The Natural Stone Institute conclude in their guide to occupational silicosis that there is no cure for silicosis; however, “with the proper equipment, training, vigilance and continual monitoring, you and your shop floor can be free of the dangers”.

Being aware that harmful silica dust is higher within engineered stone, compared to natural stone, and by monitoring for this, as well as using correct respirable protective equipment (RPE) when working with engineered stone, it allows for correct precautions to be taken to avoid silicosis.

We’ve developed the world’s first real-time silica monitor, the AIR XS Silica Monitor, and, along with other health and safety controls, this is one of the tools that will help to prevent occupational silicosis for those exposed to harmful silica dust in the workplace.

The UK’s favourite DIY and home improvement expert, Tommy Walsh, is calling for more to be done to protect workers from the dangers of silica dust.

Tommy believes that the issue of air quality on building sites should be a national concern, and that silica dust should be viewed the same way as asbestos.

While he became aware of the dangers of silica dust as an issue around five years ago, in relation to the disposal of plasterboard, Tommy says that he has not heard the issue discussed on building sites. This is in spite of the fact that 81% of those regularly exposed to silica dust are construction workers.

Tommy shared that the majority of health and safety concerns on smaller building sites are focused around obvious, external risks, such as falling from a ladder, electricity and water. As a result, he believes that more needs to be done to raise awareness of “invisible” risks, such as occupational silicosis, which is the most common chronic lung disease in the world.

He continued, “over half of the country’s construction is done by small builders and ‘one-man-band’ outfits. Air quality has always been a secondary concern to them, as they don’t know enough about it. Everyone would rather work safe than not safe, but they can’t do that if they don’t have the awareness. Health and safety can often be ignored due to cost-saving, time-saving, or ignorance, but if we can normalise the importance of air quality it will make it harder to ignore.”

Recent data has shown that respirable crystalline silica (RCS) is the biggest risk to construction workers after asbestos, with cases and exposure rising year on year. There are 12,000 deaths a year in the UK from inhalation of dust including silica in the workplace, opposed to just 142 recorded due to workplace accidents between 2020/2021. What’s more, there are an estimated 50,000 workers worldwide exposed to silica dust.

The scale of the issue is not matched by the awareness and action needed to prevent it.

Silicosis, as well as being the world’s most common occupational lung disease, can increase a person’s risk of tuberculosis, kidney disease, arthritis, and lung cancer. The consequences of occupational silicosis have been estimated to cost employers in the UK construction industry over £1 million per year.

In order to raise awareness and protect construction workers from this entirely preventable disease, we’ve launched the AIR XS Silica Monitor, the world’s first real-time silica monitor, which can provide real-time data of dangerous silica dust particles workers are exposed to across any given day.

Requiring no complicated set-up and only five minutes of maintenance a month, the AIR XS is easy-to-use and provides accurate, real-time RCS monitoring with minimal training, letting workers know if the amount of RCS content in their workspace is increasing as they work and when it has risen to dangerous levels.

Protecting the health and safety of the people who work for you is the ethical thing to do. It also makes good business sense as your people are your greatest asset.

But even if you aren’t driven by a moral or financial imperative, governments around the world are toughening up on the legislation that protects workers, so it’s not something any business can afford to ignore.

While some threats are obvious, others are invisible and incredibly hard to accurately detect, such as the deadly silica dust that are the by-product of many industries and manufacturing processes.

Silica dust is linked with severe health problems. It has been dubbed the ‘new asbestos’ and has already been the subject of litigation. Yet it’s something that has historically been impossible to monitor in real time.

Our Construction Industry Health and Safety Survey Winter 2021 shows that employers are concerned about safety, with nine out of 10 respondents recognising that worker safety is important or very important.

But it also revealed that on the ground it can be hard to meet the health and safety challenge, particularly when it comes to dust monitoring, which for a fifth of respondents accounted for half of their safety budget.

This in-depth report looks at how real-time, wearable dust monitoring technology can help to solve the issues from the findings of the Construction Industry Health and Safety Survey Winter 2021.

The findings ultimately mean that it’s clear we need a new approach to dust monitoring. One that looks to the future and is inspired by the intelligent tech revolutionising every other aspect of our lives.

It’s time to act now to tackle danger of hazardous dusts, like silica dust, by investing in smarter solutions to protect the air we breathe, with real-time dust monitoring.

***

What might seem like a nine-year journey to develop the Trolex AIR XS Silica Monitor actually goes back 150 years. Our new real-time silica detection technology has surprising origins…

It starts at a time when miners had next to no protection, especially from harmful silica dust, and to a place that ‘roofed the world’; Snowdonia’s beautiful, bleak, Blaenau Ffestiniog.

Recently awarded UNESCO heritage status, it was here that my grandfathers, great grandfathers, uncles, and cousins all worked, mining slate.

Arawn and Ieuan. Dai and Dewi. Merfyn and Maldwyn.

And it’s here that many of them died, often as young as in their 40s, from occupational silicosis.

No health and safety. No silica detection and prevention. No chance.

It makes the work we do at Trolex all the more personal and all the more poignant.

And it’s a major part of the reason we’ve worked so hard to solve the age-old problem of occupational silicosis.

So that modern-day miners and quarry workers – in fact, anyone who might come into contact with silica in their working lives, from construction workers to plasterers, factory workers and stonemasons – will never have to suffer the same fate as my forefathers.

And all it took was vision and ingenuity, optimism and grit, and endless trips to the bank manager. And despite being told we’d never do it – we’ve done it.

New real-time dust monitoring technology that offers new hope to people who previously had no hope of avoiding an unnecessary, painful and premature end to their lives caused by occupational lung diseases.

It’s called the AIR XS Silica Monitor.

And it’s astonishing.

The world’s first real-time silica detection technology saving lives all over the world – made of legends.

As they used to say in the back bar at the Miners Inn in Blaenau…

Dyma i chi fechgyn!*

Drop me a line and I’ll tell you everything you need to know about the AIR XS Silica Monitor and the many ways it can benefit your staff and your business.

*Here’s to you, boys!