It’s no secret there are different health and safety concerns for the industrial sector than most others. One of the most prevalent to arise in recent times is about silica dust exposure, and what this means for those working in areas with this risk.

The nature of the work being done, and the environments it’s done in, have highlighted plenty of areas that need to be improved on – not only for the business as a whole but for the benefit of employees, without whom the industry would grind to a halt.

Why is silica dust exposure important, and what can be done to protect those at risk?

Silica, dust, and silicosis

The first thing to know is silica dust exposure is not a new thing. It’s been happening for a long time, but as industrial processes and technology have improved over the years, we’ve been able to learn more about it. Knowing what it is, where it comes from and, more importantly, what the effects of it are allow us to make changes to help everyone.

What is silica?

Silica, also known as quartz, is a natural substance found all around the world. Sand, gravel, clay and some rocks and stones all include silica. While a material in its own right, it’s also a part of many common building materials like concrete, mortar, bricks and tiles. It’s not unusual for any building or construction site to work with silica dust.

That’s right, even your home is made with some silica.

Where does silica dust come from?

Whenever silica is present, there’s a risk of silica dust exposure. Industrial workplaces and construction sites are just a couple of examples of places where the risk of inhaling silica dust is high.

Grinding, drilling, cutting and similar tasks releases dust into the air. Depending on the material, this can be mostly harmless or, in the case of silica, dangerous.

Silica dust, or respirable crystalline silica (RCS), is so fine that it can reach deep into the lungs when inhaled. If this happens often enough over a long period of time, it can lead to serious respiratory illnesses or even lung cancer.

What causes silicosis?

Silicosis is a serious respiratory illness caused by silica dust exposure over a long time. The longer someone is exposed to silica dust, the worse the symptoms of silicosis will become. Despite this, if exposed to extremely high levels of silica dust over a shorter period, acute silicosis can develop quickly, so you need to be aware of the risk.

According to the CITB, about 3,000 construction workers suffer from lung and breathing problems from their work each year. Not only is this bad for businesses, but worse for workers. In 2005, the HSE estimated silica dust exposure was responsible for more than 500 construction workers deaths.

What are the symptoms of silicosis?

The symptoms of silicosis can include a persistent cough, shortness of breath, exhaustion and more. Depending on the severity of silica dust exposure, and for how long, the symptoms can appear very quickly or over a much longer period of time.

After years of exposure, these symptoms will worsen and could lead to respiratory failure. This can often be fatal.

Right now, silicosis can’t be cured. The lung damage is irreversible, but it can be managed – especially if caught early. If you’re at risk of silica dust exposure and notice these symptoms, it’s essential to go for a check-up to be safe.

How to reduce the risk of silicosis and silica dust exposure

While silicosis is a serious condition, and silica dust exposure is a real hazard, there are ways to reduce the risk of inhaling the substance.

We’ve outlined five methods that increase the protection of workers in high risk areas involving silica dust – and these will also work with other hazardous airborne particulates, too.

1. Wear suitable workwear in environments where there’s a risk of silica exposure

One of the most effective ways of minimising silica dust exposure is to provide your workers with personal protective equipment (PPE), such as respirators, which cover the nose and mouth.

Disposable respirators only give minimal protection and need to be changed regularly, so you’ll need to assess the working environment to decide if they can adequately protect your workers from silica dust inhalation – and whether this is a cost-effective solution.

For even more hazardous environments, half or full-face respirators offer a better degree of protection – but they must be cleaned after every use.

2. Keep equipment clean in workplaces with high levels of silica

Contamination can be a major cause of concern in these environments. Workwear can be contaminated by silica dust – which is sometimes so fine that it cannot be seen. Even if something looks clean, it should always be washed separately to avoid the risk of contamination and to remove any invisible silica dust particles.

There are specialist laundries that offer industrial cleaning services to reduce the risk further. Additionally, any equipment used in areas with silica dust should be thoroughly cleaned after each use and stored in a dust-free place.

Refer back to the manual of each piece of equipment for specific cleaning and maintenance details, but some general tips for cleaning dusty equipment include:

- switching off and unplug electrical equipment

- using a light spray nozzle or lightly damp cloth over the surface

- dismantling tools and clean under covers and in between small pieces

- using a soft bristle brush to get in cracks and gaps, as well as cleaning notches on blades

- leaving to dry before reassembling

- test equipment works before use.

3. Use engineered controls for dust suppression

With local exhaust ventilation (LEV), you can remove dust at its point of origin. This is a very effective form of dust suppression, as silica dust containment systems continuously remove and filter the contaminated air.

There are a number of brands and devices out there to handle different levels of dust particles and environments. These range from built-in ventilation systems to portable fans and blowers that can be placed strategically in an area.

4. Use wet methods when working in dust-heavy areas

Before carrying out a task that produces a lot of dust, such as cutting or drilling, you can spray water on the material and area. This is known as the wet method, and suppresses dust particles being expelled into the air as they’re trapped by the moisture.

Regular water works for this, and all you need is a spray bottle. A few sprays of the water onto the material will drastically reduce dust particles in the air.

This is a useful method for reducing silica dust exposure, but it’s not perfect. Even when using the wet method, dust monitoring and respiratory protective equipment should be utilised.

5. Monitor dust levels

A dust monitor can assess the air quality in the workplace, whilst also measuring the size and concentration of any airborne particles, such as silica dust. This is one of the best preventative measures you can take to help reduce the risk of silicosis, as constantly monitoring the air in real time allows you to easily spot any areas of concern.

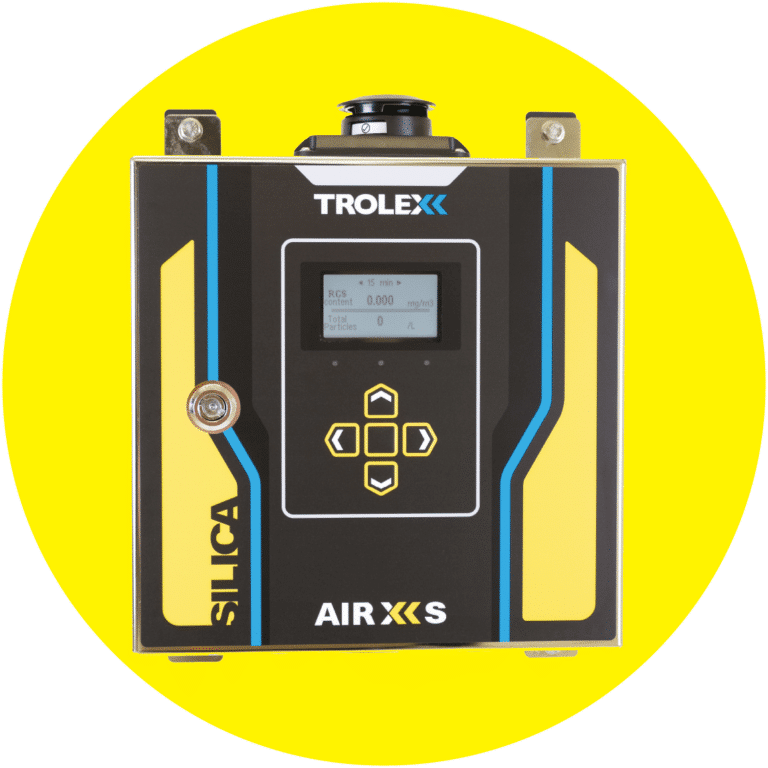

Most dust monitors can only measure one particle size at a time, but the AIR XD Dust Monitor, XD One Portable Dust Monitor, XD1+ Personal Dust Monitor and AIR XS Silica Monitor uses advanced laser technology to monitor multiple sizes at once, adding an extra level of protection against both silica dust exposure and silicosis.

Find out more about reducing silica dust exposure

We can’t state enough just how much of a hazard silica dust exposure is – to both businesses and workers. Anything that can be done, such as the steps above, helps ensure the well-being of the workers most at risk. The more steps you take, the better the conditions and lower the chance of developing silicosis.

Reducing silica exposure in the workplace requires commitment, but if you’re interested in finding out how to protect your workers against the dangers of silica inhalation and reduce the risk of silicosis in your workplace, get in touch using the contact form below.