Worktop Fabricators Federation (WFF) encouraged their members to implement real-time silica monitoring technology to support their existing control measures when working with materials containing crystalline silica.

The WFF is a non-profit organisation for those using industrial fabrication methods to make worktops from natural stone and similar man-made materials, who promote professionalism, installation and most notably best practice across the worktop fabrication industry.

Aiming to consistently follow best practice when working with engineered stone, we spoke to Nigel Fletcher, Operations Manager at the WFF, who have recently purchased an AIR XS Silica Monitor to allow their members to actively monitor for and distinguish respirable crystalline silica (RCS) in real-time, regardless of their occupational environment, when following best practice.

“The WFF is committed to promoting best practice when it comes to working with silica and that includes water suppressed cutting, using the correct and most effective PPE and recommending annual health checks for workers” said Nigel.

It’s essential that workshops using silica containing products adhere to best practice, including implementing control measures to reduce RCS, which poses a threat to workers health, WFF also sees strong value in implementing real-time RCS monitoring to ensure control measures are working to the highest standard to protect workers.

Nigel continued; “The WFF has partnered with Trolex to give a real-time solution to the industry. Real-time RCS monitoring has huge advantages, as it’s a way of safeguarding and understanding the environment around the workshop. Looking at real-time data whilst in the workshop, to see how effective best practices and control measures are, helps safeguard the workforce.”

WFF members themselves have a priority of ensuring that workers and occupational environments remain safe and at minimal risk of RCS exposure.

Cambrian Granite are a member of the WFF. Rob Kunkel, Business Develop Manager at Cambrian Granite said, “when protecting our workers from the dangers of RCS, we always use wet polishing and as much CNC work as possible.”

For Rob and his team at Cambrian Granite, the benefit of knowing RCS levels in real-time is paramount; “the real-time data helps keep our staff well protected by making sure areas of both the factory and rest areas are safe environments to be in.”

The goal for the Federation with this partnership is to enable a safer future and positive workplace environment for all their members. “We are hopeful that our partnership with Trolex supports our members, future membership and the industry in understand how best practice and modern technology can work in partnership.” This goal is strengthened by supporting the adoption of real-time RCS monitoring.

For Nigel the Federation’s goal to provide a safer future and positive working environment for all their members is strengthened through our collaboration as we seek to support the adoption of real-time RCS monitoring.

It’s not just a case ensuring workplaces are safe from RCS for WFF members, but also to effect positive change when working with RCS in the future, thanks to this partnership; “one of the WFF’s goals is to half the workplace exposure limit. Real-time monitoring can have the capacity to actively guide and aid members to ensure their RCS levels are consistently in line, or below, and workplace exposure limits.”

We hear it every day and it’s becoming a staple in everything we do. Whether it’s information on the weather or travel, valuable data relating to your health and lifestyle, or money and banking, our lives would be severely impacted without receiving real-time information, alerts and data.

When it comes to health and safety in the workplace, real-time monitoring and real-time data is vital to managing control measures for exposure to hazardous substances, whether it be dust, gases or other substances. Real-time monitoring allows workplaces to see spikes in exposure do something about it.

“Real-time monitoring is instant, in the moment, meaning you can do something about a problem and implement control measures.” – said Joe Marais, Occupational Hygienist and Product Development Manager at Trolex. “It allows you to try a new control measure and have a very quick indication of whether that has been successful or not in reducing the hazard.”

When it comes to workplace health and safety, effective measures must be taken to protect workers, and real-time monitoring is the most effective way to provide this. “Real-time monitoring is a tool you can use in combination with the Hierarchy of Controls. Unfortunately, in certain circumstances like with crystalline silica, which is naturally occurring in so many materials, you can’t necessarily just eliminate it, and it can be quite difficult to substitute it.”

“So, for the most part, you will need to introduce engineering controls and that’s where real-time monitoring comes in,” When carrying out an action that generates extremely large volumes of dust, or you know for a fact you’re being exposed to dust, you can introduce water suppression or other extraction methods to the activity to reduce your exposure and have an instant indication of whether the control measures have been effective.

“If you’re able to incorporate real-time monitoring when applying the Hierarchy of Controls, you’ll quickly see whether what you’re doing to mitigate the risks of dust exposure is effective or not.”

“You’re able to see the exposure concentration in real-time before the control measure is introduced, then once you introduce the control measure, you can immediately see if there is a drop in the exposure concentration.”

“The key word is ‘understanding’. Do all workers truly understand why it’s being said when it comes to protecting themselves from hazardous substances or are they just listening to it and following instructions, unaware of whether they’re doing it right? Explaining something to someone so they can understand the long-term implications is the key. Or better, showing them first hand.”

“Telling somebody in a backyard garage ‘You’re exposed to 20% of the crystalline silica exposure limit’ might not tell them anything useful. Putting it into a format where they can take it in, understand it and do something about it is where we can see real value and real-time monitoring gives us this.”

“Showing someone, whilst they’re physically doing part of their job ‘this specific activity is causing x amount of dust’ and then showing them the changes in dust levels, in real time, after the introduction of control measures can be vital not only in increasing understanding for one worker, but awareness across the entire workforce.”

With real-time monitoring and real-time data, you’re not only monitoring levels of hazardous substances as they happen but monitoring the effectiveness of any engineering controls and workplace safety as and when you need to, enticing others to understand and become aware of the importance of workplace health and safety.

With an estimated 1 million people dying globally from the inhalation of dust in occupational environments every year, now is the time to protect your workers. Real-time dust and silica monitoring provides instant alarms, alerting all workers at risk of dangerous dusk regardless of their application, processes or industry.

We’re continuously innovating our real-time dust monitoring technology to give you access to the information to effect change and keep your workers safe from hazardous respirable dusts. With a range of real-time dust monitoring options, we’re here to help you protect your workers.

Whether that is heavy-duty area monitoring for high dust loading environments, personal dust monitoring for individual monitoring needs, or silica monitoring for working environments with high respirable crystalline silica (RCS) content, such as stonemasonry, tunnelling or quarrying.

Our full dust monitoring comparison guide helps to identify the key aspects of each of our real-time dust monitors, highlighting the key USPs and capabilities of each product to help keep your workforce safe from harmful respirable particulates.

With an estimated 1 million people dying globally from the inhalation of dust in occupational environments every year, now is the time to protect your workers. Personal and portable dust monitoring provides a simple solution for all workers at risk of dangerous dusk regardless of their application, processes or industry.

We’re continuously innovating our real-time dust monitoring technology to give you access to the information to effect change and keep your workers safe from hazardous respirable dusts. Which is why we have developed the XD1+ Personal Dust Monitor and the XD ONE Portable Dust Monitor.

Both products provide a unique approach to personal, handheld, portable dust monitoring. It’s dust monitoring that doesn’t get in the way, that’s small and versatile enough to give you the freedom to do your job whilst making zero compromise on accuracy and reliability, remaining easy to use, simple to maintain and cost effective.

Our full portable vs personal dust monitoring comparison guide helps to identify the key aspects of each of portable and personal real-time dust monitors, highlighting the key USPs and capabilities of each product and helping you to best protect your workforce from harmful respirable dust in the workplace.

Where it’s not possible to completely ban the use of products and materials which create excess hazardous dust, one common solution, it seems, is imposing litigation and heavy fines for businesses who expose workers to dangerous dust.

Over the last 10 years, businesses in multiple industries that have failed to adequately protect workers from excess dust exposure outlined within the hierarchy of controls, such as elimination or substitution of hazardous substances, or introducing control measures, have suffered enormous financial litigation for exposing people to hazardous dust which subsequently result in irreversible lung diseases.

Whether it’s in heavy duty and highly dusty occupational locations, like construction, quarrying or mining, or just general public spaces or low dust and eco-friendly environments, the cost of dust exposure is large.

Leading medical staff in the UK, writing for medical journal ‘Thorax’, are calling for industries and governing bodies to follow Australia’s new legislation and ban the use of engineered stone, commonly used for kitchen worktops.

It comes after cases of silicosis linked to engineered stone exposure recently came to light globally. Workers who have been exposed to engineered stone quartz and dust are now being affected by and diagnosed with severe lung problems, linked to inhaling such dust. Earlier in the year, it had prompted the Australian government to act and ban the use, manufacturing, and production of engineered stone across the entire country.

Now the UK is being urged to do the same, with the first cases of silicosis related to engineered stone production have now been reported in the country. Various medical staff who have treated workers diagnosed with these cases of silicosis are calling for similar action to be taken in the UK as in Australia.

According to British newspaper i the first 8 cases of silicosis linked to engineered stone use have been confirmed, all of which are men. The average age of all 8 men is 34, with the youngest to be diagnosed just 27 years old. Of the 8 cases, 1 man has died, and 2 others have been referred for lung transplant assessments.

The article from i features an interview with one of the diagnosed workers, Malik al-Khalil, a stonemason who is just 31. After working with engineered stone for 5 years, Malik was diagnosis with silicosis, contracted after cutting engineered stone slabs in a small London workshop. Malik said, “I want to let all the people working in this work know what’s happening from this material” and believes the only solution to this growing problem is a nationwide ban of the product; “Of course [it should be banned] because the silicosis is coming from this material.”

It’s not just Malik and fellow diagnoses patients who are calling for engineered stone to be banned in the UK. Dr Johanna Feary, a respiratory consultant from the Royal Brompton Hospital where Malik al-Khalil is being treated, and lead author for ‘Thorax’, has also highlighted her concerns over exposed to the product. Dr Feary told i “We’ve been anticipating that we would start seeing cases in the UK at some point. That moment has arrived now.”

The team of doctors writing in ‘Thorax’, who highlighted the first 8 cases, have also called for a legal requirement to report cases of silicosis, as well as calling for the implementation of health and safety regulation for both small companies and national guidelines to treat and monitor for silicosis.

You can read the full article from i newspaper here.

With an estimated 1 million people dying globally from the inhalation of dust in occupational environments every year, now is the time to protect your workers. Personal and portable dust monitoring provides a simple solution for all workers at risk of dangerous dusk regardless of their application, processes or industry.

We’re continuously innovating our real-time dust monitoring technology to give you access to the information to effect change and keep your workers safe from hazardous respirable dusts. Which is why we have developed the XD1+ Personal Dust Monitor and the XD ONE Portable Dust Monitor.

Both products provide a unique approach to personal, handheld, portable dust monitoring. It’s dust monitoring that doesn’t get in the way, that’s small and versatile enough to give you the freedom to do your job whilst making zero compromise on accuracy and reliability, remaining easy to use, simple to maintain and cost effective.

With an estimated 1 million people dying globally from the inhalation of dust in occupational environments every year, now is the time to protect your workers. Real-time dust and silica monitoring provides instant alarms and alerts for all workers at risk of dangerous dusk regardless of their application, processes or industry.

We’re continuously innovating real-time dust monitoring technology to give you access to the information to effect change and keep your workers safe from hazardous respirable dusts. With a range of dust and silica monitoring options, we’re here to help you protect your workers.

Whether that’s heavy-duty area monitoring for high dust loading environments, personal dust monitoring for individual monitoring needs, or silica monitoring for working environments with high respirable crystalline silica (RCS) content, such as stonemasonry, tunnelling or quarrying.

Real-time monitoring offers solutions to us in our everyday lives. Whether it’s the real-time alerts that tells you that you’re at risk or in danger, or the subsequent data which provides you accurate information on what you’re monitoring, real-time monitoring has become an essential part of our lives.

But what about real-time monitoring when it comes to enhancing the workforce? You’d rely on real-time monitoring and alarms to tell you there’s a fire in your home, so why wouldn’t you rely on real-time monitoring to tell you if you were a risk as serious to your health at work? You’d rely on real-time data to tell you if you needed to track nutrition or health trends, so why wouldn’t you rely on essential data in real-time in the workplace?

Whether it’s for the health and safety of you and your colleagues, to better understand the processes and efficiency of the business, or just to help aid decisions, real-time monitoring can provide valuable data to workforces across a whole range of industries. Whether you are monitoring for hazardous substances like dust or silica, or monitoring for HAV, sound levels or proximity measures, real-time monitoring can enhance your workforce.

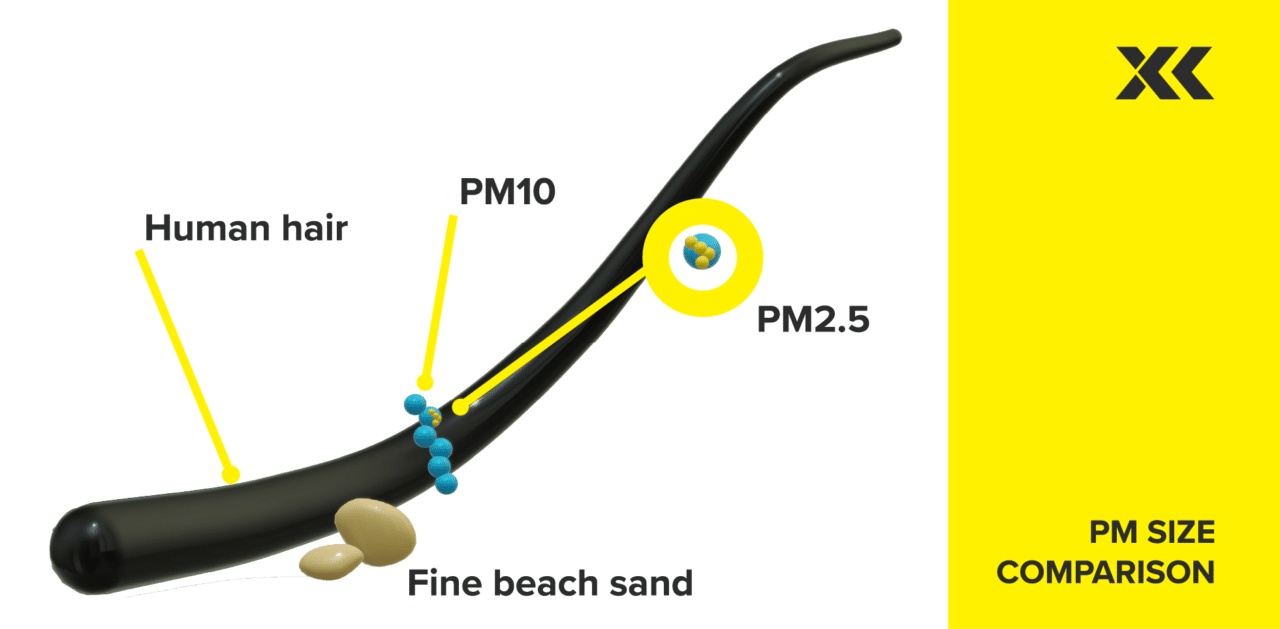

‘PM’ or particulate matter, also known as particle pollution is the term for a mixture of solid particles and liquid droplets found in the air.

It’s estimated that air pollution is linked to 43,000 deaths per year in the UK. Worldwide, at least 7 million people die each year from exposure to air pollution, with 91% of the worldwide population living in locations where the air quality exceeded the World Health Organisations (WHO) air pollution guidelines.

These guidelines state that that annual average concentrations of PM2.5 should not exceed 5 µg/m3 and PM10 should not exceed 15 µg/m3 (both for 24-hour periods). According to the WHO, ‘fine particulate matter at PM2.5 can penetrate through the lungs and further enter the body through the blood stream, affecting all major organs’. Exposure to dust at PM2.5 can cause serious disease to the respiratory system, such as lung cancer and COPD, and also can effect cardiovascular diseases, such as a stroke.

The image below demonstrates PM2.5 and PM10 size in comparison to a single human hair and a grain of sand.

The Department for Environment Food & Rural Affairs (DEFRA), the UK government ministerial department for environment protection, have also highlighted the severity of exposure to air pollution. This growing concern for the UK government estimated in 2010 that the cost of health impacts of air pollution was likely to exceed estimates of £8bn to £20bn.

Although between 2005 and 2022, the UK’s PM2.5 emissions decreased by 41%, emission levels have been relatively steady with small annual fluctuations in the last decade. Industrial combustion is a major source of PM emissions, as well as emissions from industrial production also playing a major part, which can be linked to heavy-dust industry where hazardous particulates can become airborne. Despite some reductions in PM emissions, the threat still very much remains.

A solution to this is real-time dust monitoring. Real-time particulate monitoring allows people in heavy dust loading environments, including industrial applications, to not only understand, but alert them instantaneously when they are exposed to dangerous levels of air pollution. For example, our AIR XD Dust Monitor can alert people in real-time when legislative levels of µg/m3 are breached, over a time-weighted average (TWA) 8-hour period, for both PM2.5 and PM10.

This technology not only offers a simple solution to individuals at high risk of exposure to air pollution by providing instant alerts, but also can help to prevent exposure in the future, as at-risk individuals can learn exactly when and where exposure to air pollution is highest and will likely occur. Thanks to real-time monitoring, both in the UK and Worldwide, we can reduce exposure to air pollution.