Real-time monitoring offers solutions to us in our everyday lives. Whether it’s the real-time alerts that tells you that you’re at risk or in danger, or the subsequent data which provides you accurate information on what you’re monitoring, real-time monitoring has become an essential part of our lives.

But what about real-time monitoring when it comes to enhancing the workforce? You’d rely on real-time monitoring and alarms to tell you there’s a fire in your home, so why wouldn’t you rely on real-time monitoring to tell you if you were a risk as serious to your health at work? You’d rely on real-time data to tell you if you needed to track nutrition or health trends, so why wouldn’t you rely on essential data in real-time in the workplace?

Whether it’s for the health and safety of you and your colleagues, to better understand the processes and efficiency of the business, or just to help aid decisions, real-time monitoring can provide valuable data to workforces across a whole range of industries. Whether you are monitoring for hazardous substances like dust or silica, or monitoring for HAV, sound levels or proximity measures, real-time monitoring can enhance your workforce.

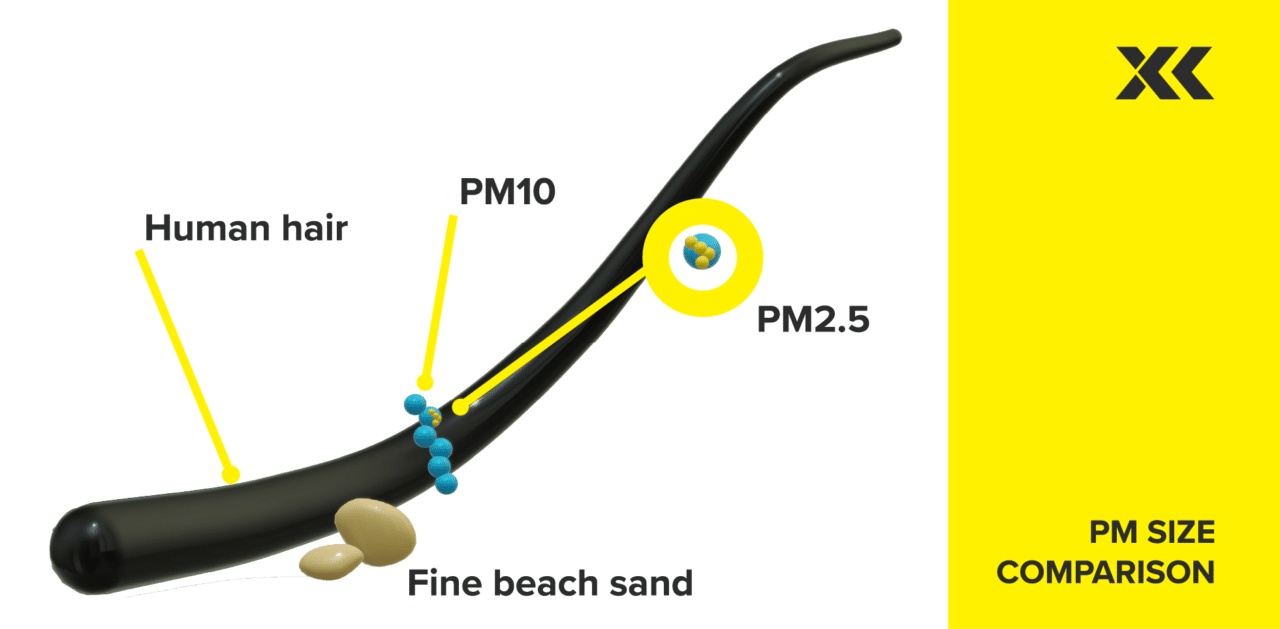

‘PM’ or particulate matter, also known as particle pollution is the term for a mixture of solid particles and liquid droplets found in the air.

It’s estimated that air pollution is linked to 43,000 deaths per year in the UK. Worldwide, at least 7 million people die each year from exposure to air pollution, with 91% of the worldwide population living in locations where the air quality exceeded the World Health Organisations (WHO) air pollution guidelines.

These guidelines state that that annual average concentrations of PM2.5 should not exceed 5 µg/m3 and PM10 should not exceed 15 µg/m3 (both for 24-hour periods). According to the WHO, ‘fine particulate matter at PM2.5 can penetrate through the lungs and further enter the body through the blood stream, affecting all major organs’. Exposure to dust at PM2.5 can cause serious disease to the respiratory system, such as lung cancer and COPD, and also can effect cardiovascular diseases, such as a stroke.

The image below demonstrates PM2.5 and PM10 size in comparison to a single human hair and a grain of sand.

The Department for Environment Food & Rural Affairs (DEFRA), the UK government ministerial department for environment protection, have also highlighted the severity of exposure to air pollution. This growing concern for the UK government estimated in 2010 that the cost of health impacts of air pollution was likely to exceed estimates of £8bn to £20bn.

Although between 2005 and 2022, the UK’s PM2.5 emissions decreased by 41%, emission levels have been relatively steady with small annual fluctuations in the last decade. Industrial combustion is a major source of PM emissions, as well as emissions from industrial production also playing a major part, which can be linked to heavy-dust industry where hazardous particulates can become airborne. Despite some reductions in PM emissions, the threat still very much remains.

A solution to this is real-time dust monitoring. Real-time particulate monitoring allows people in heavy dust loading environments, including industrial applications, to not only understand, but alert them instantaneously when they are exposed to dangerous levels of air pollution. For example, our AIR XD Dust Monitor can alert people in real-time when legislative levels of µg/m3 are breached, over a time-weighted average (TWA) 8-hour period, for both PM2.5 and PM10.

This technology not only offers a simple solution to individuals at high risk of exposure to air pollution by providing instant alerts, but also can help to prevent exposure in the future, as at-risk individuals can learn exactly when and where exposure to air pollution is highest and will likely occur. Thanks to real-time monitoring, both in the UK and Worldwide, we can reduce exposure to air pollution.

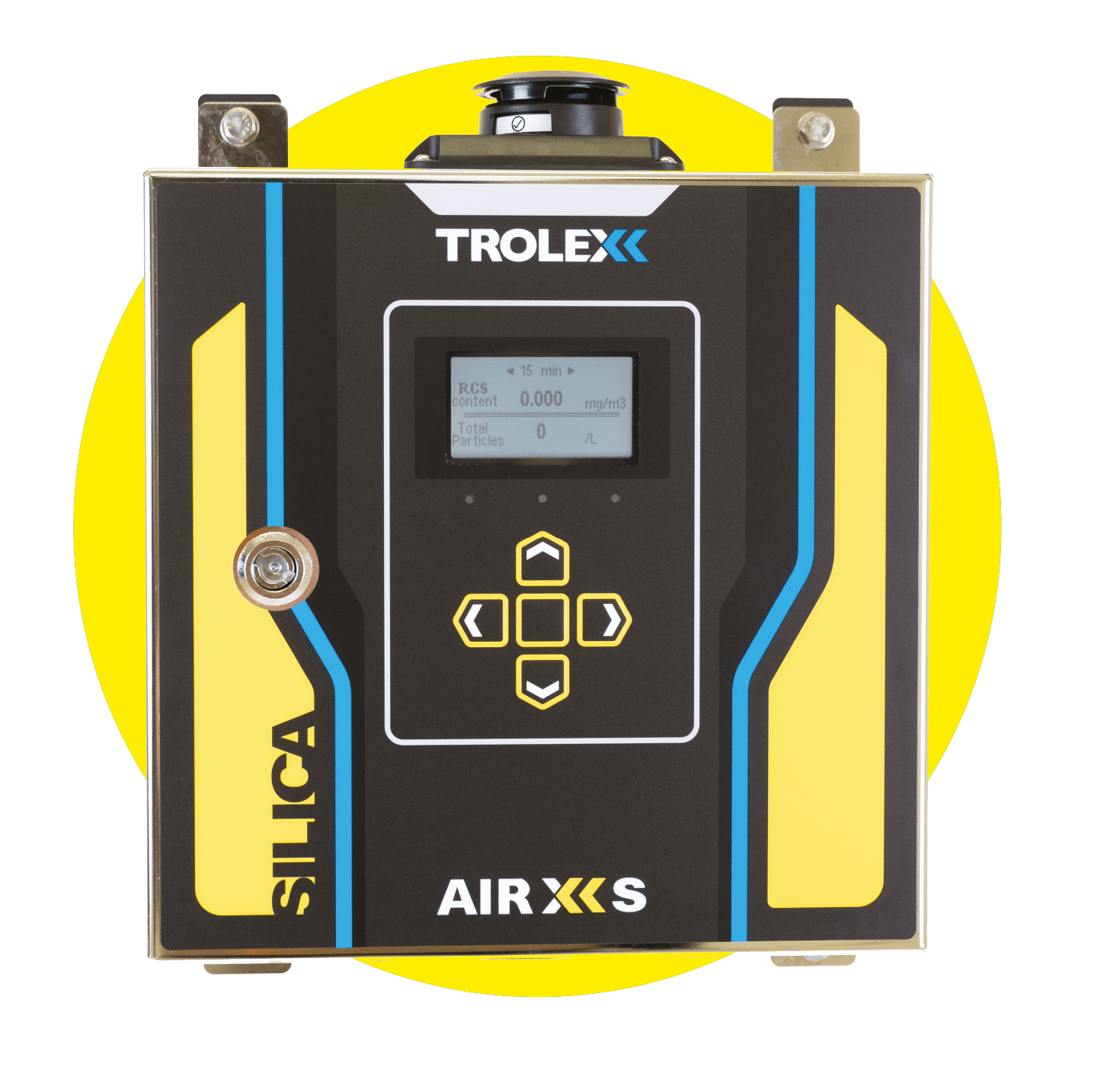

The AIR XS Silica Monitor leverages cutting-edge Optical Refraction Technology (ORT) to enhance workplace safety by providing real-time monitoring of respirable crystalline silica (RCS). Unlike traditional particle monitors, AIR XS distinguishes and measures RCS content, enabling immediate detection and response to harmful silica dust levels. This technology is crucial in combating occupational lung diseases such as silicosis, which affects millions of workers globally.

Current monitoring methods, like gravimetric sampling, are time-consuming and often deliver results too late to prevent exposure. In contrast, real-time silica monitoring offers immediate data, significantly reducing the risk of occupational silicosis by enabling prompt action to mitigate hazardous conditions. The importance of such real-time data is highlighted by cases like Joanna McNeill’s, who developed silicosis at the age of just 36. Her story, like many others underscores the necessity for continuous monitoring to protect workers from the threat of silicosis, regardless of their occupational environment.

Our real-time RCS monitor, AIR XS provides a real-time solution to this threat. Workers are not only alarmed and alerted when silica levels exceed legislative limits but can work to best practices by implementing AIR XS with the Hierarchy of Controls, supporting proactive measures to eliminate or minimise exposure to RCS. This move to real-time monitoring as a solution to the threat of silicosis has also been noticed by governing bodies, like the All-Party Parliamentary Group on Respiratory Health.

To learn more about how this real-time solution not only enhances worker safety but also streamlines business operations, click the link below to read the case study in full.

A manufacturer of prestigious natural stone, Burlington Stone have quarried for over 200 years across the English Lake District, extracting and crafting a diverse range of signature British natural slate and stone products.

Individuals across their workforce are often exposed to hazardous substances, most notably airborne dust, including silica dust. Burlington Stone trialed two XD1+ devices on their site for a month to see how real-time, personal dust monitoring would improve their safety processes.

After the trial, we spoke to Health and Safety Manager, Peter Walker, about the success of the trial and some of the major benefits which Burlington Stone’s workforce found deploying XD1+ Personal Dust Monitor units in their day-to-day processes.

Launched in 2022, the AIR XS Silica Monitor isn’t like other silica monitors on the market. If you’ve been in the Health and Safety space, it’s likely you’ll know about Optical Particle Counter (OPC), also known as “light-scattering”; but our patented AIR XS isn’t just another OPC.

Unlike traditional Optical Particle Counters (OPCs) that rely on light scattering and interruptions to deduce particle size and quantity, the patented Optical Refraction Technology (ORT) used in the AIR XS shines a laser through each particle, capturing its refraction on multiple sensors.

In our blog below, we reference Pink Floyd’s 1973 album Dark Side of the Moon to explain one way to how ORT works. It’s not exact by any means but the refraction of the light coming out of the prism shows an example of how light refracts, similar to a crystalline particle.

Silicosis is now the most common occupational lung disease in the world, with silica dust described as ‘the new asbestos’ due to the extreme threat it poses to human health.

Silica dust (respirable crystalline silica (RCS)) is extremely harmful to human health due to its physical and biological properties.

It affects around 50,000,000 workers in a wide variety of industries all around the world and prolonged exposure leads to silicosis and a wide range of other diseases, most of which are untreatable and often lead to long-term disability and/or death.

The potential for harm is even worse than that when you consider that asbestos is one of many different silica compounds and silica is the most proliferate mineral on earth; present in bricks, sand, stone, concrete, glass, cement and many other construction and building materials. 99% of deaths in occupational settings, are caused by the inhalation of dangerous particulates, with the other significant factor in this statistic being the extreme difficulty in monitoring in real-time for these killer particulates

It has never been possible to reliably detect and distinguish silica dust in real time in the real-world settings in which workers are exposed to it – until now.

The white paper looks at the background of silica exposure, the current methodologies employed to monitor it and the new technological advancement that has led to the development of a field-ready product for the first time in history.

Legislated limits of exposure have been tightening up in most major economies as the harm being caused becomes known, but reductions in limits and the implementation of these limits have been hampered by the lack of real-time accurate and reliable monitoring capability.

This technology has the potential to change the way industry, governments, businesses and workers themselves respond to the threat of RCS exposure in the workplace, and as such, it can be the beginning of the end for occupational silicosis. Not only does it improve health and safety outcomes for frontline workers, but it also reduces costs for businesses whilst giving them back control over their working environment.

Perhaps most importantly of all, it gives legislative bodies the tool they need to create and implement workplace exposure limits (WELs) that genuinely protect workers from harm, at a cost industry can bear, ending decades of debate over what the limits should be and how practicable it is for industry to meet them.

In 2020, the All-Party Parliamentary Group for Respiratory Health (APPG) issued the report “Silica, the next asbestos?”, which examined the disproportionate effect of silica dust to construction workers’ lives.

Since the publication of that report, the APPG were contacted by a number of experts on the subject matter, who highlighted the advances in risk reduction and the particularly promising rise of real-time dust and silica monitoring technology.

“Trolex believe that the most obvious and immediate benefit of real-time monitoring is in improving safety for those potentially exposed to silica in the workplace.”

The new, revised report, titled “Improving Silicosis Outcomes in the UK” also explored these new silicosis prevention strategies, including some input from Trolex on the subject matter. From this, the APPG raised several clinical and regulatory recommendations to protect workers from the dangers of occupational silicosis going forward.

“We recommend that the Health and Safety Executive (HSE) assesses and determines the data and technology needed to allow the UK to reduce the WEL for work with silica to 0.05mg/m3.”

The recommendations from the APPG’s report indicate a number of changes need to be made in order to improve safety across all UK industries which use silica. These recommendations focus on both ways to prevent exposure to dangerous respirable crystalline silica (RCS) in the workplace, including improvements in education, real-time monitoring and reducing exposure limits, as well as improving health and support for those who currently suffer with silicosis.

“We recommend that the HSE actively considers and consults with industry on the positions of real-time monitoring to complement the hierarchy of controls.”

The effects of silicosis in the stone industry is not an unknown issue.

But to what extent are stone workers aware of this issue? Are the specific causes of silicosis in the stone industry common knowledge?

A scientific report from nature.com highlights the difference between engineered stone and natural stone, in relation to their silica content, shedding some light on where the cause of silicosis could lie in the stone industry.

Silicosis is one of the most dangerous respirable lung diseases in the workplace, especially when exposure to harmful silica dust is a common occurrence, such as in the stone industry.

It is estimated that globally, 40 to 50 million workers are exposed to silica dust in the workplace.

The Natural Stone Institute guide to awareness and prevention of silicosis determines that exposure to respirable crystalline silica (RCS), specifically in the stone industry comes from cutting or grinding materials, most commonly which contain quartz, is composed of silica dust.

The purpose of the study from nature.com was to see, in relation to RCS, what the most threatening scenario was for worker’s health, in real time, when working with different compositions of stone.

In the study, 12 engineered stones were assessed against three natural stones – white marble, white granites and black granites. By dry-cutting all stones, silica dust was captured in a closed environment and subjected to various assays to determine both chemical and physical properties.

The 12 engineered stones’ silica content varied from one another, and the total RCS content made up of quartz and cristobalite ranged from 70.4% to 90.9%. By comparison, the natural stone’s silica content ranged from 3.5% to 30.1%, marking a clear difference.

As well as this, the dry-cutting of engineered stone generated finer RCS particles with one engineered stone having an average size of as little as 190 nanometres, meaning it could reach deeper in the lungs, in turn causing more damage. Contrastingly, the smallest average particle size of the natural stone was black granite, with an average size of 503 nanometres.

The results of this study concluded that silica dust emissions from engineered stones had a much higher concentration of quartz and cristobalite, therefore having a higher silica content and subsequently more damaging impact on respiratory health.

Ultimately, the report concluded that the higher the silica content of the stone, as well as the smaller size of RCS particles, the more dangerous it is to respirable health.

The Natural Stone Institute conclude in their guide to occupational silicosis that there is no cure for silicosis; however, “with the proper equipment, training, vigilance and continual monitoring, you and your shop floor can be free of the dangers”.

Being aware that harmful silica dust is higher within engineered stone, compared to natural stone, and by monitoring for this, as well as using correct respirable protective equipment (RPE) when working with engineered stone, it allows for correct precautions to be taken to avoid silicosis.

We’ve developed the world’s first real-time silica monitor, the AIR XS Silica Monitor, and, along with other health and safety controls, this is one of the tools that will help to prevent occupational silicosis for those exposed to harmful silica dust in the workplace.

Trolex are excited to be partnered with Active Environmental Solutions (AES), working together to protect workers from the dangerous and often irreversible consequences of occupational lung diseases caused by dust inhalation.

With AES’s specialist knowledge of occupational health and safety in Australian industries and Trolex’s leading safety technology, the opportunity of delivering solutions to prevent the dangers of dust inhalation for Australian workers, is not just a possibility, but now a reality.

AES want to spread awareness of the dangers of occupational lung diseases caused by dust inhalation. And in the case of dust monitoring, spreading awareness that new real-time dust monitoring technology to help prevent lethal occupational respiratory diseases now exists.

The opportunity to partner with Trolex was welcomed by AES, as it means that they can merge their expertise in occupational health using Trolex’s leading safety technology.

This creates the best solutions to their respective industries.

This simple message appealed to AES, and to Aleks Todorovic MSc, (OHP), Managing Director of AES’s team of Australian Occupational Safety experts at AES, as it aligned perfectly with the workers they seek to protect:

“Many businesses intuitively know the benefit of a broad threat detection – they just don’t know they know it, or perhaps how they go about implementing such devices – it’s our job to awaken that knowledge and show them there are new and effective dust detection technologies such as the Trolex AIR XD Dust Monitor, the XD ONE Personal Dust Monitor and most recently, the AIR XS Silica Monitor.

There are no arm twisting, or heavy sales techniques involved. Just a clear and simple presentation of responding to the facts.

Which is why Trolex and AES are working hard to provide further education to Australia’s mining, tunnelling, quarrying and construction industries, where workers are exposed to dangerous forms of respirable dusts.

This common goal of providing and expert knowledge and specialist equipment to these industries is the drive needed to inevitably reduce instances of occupational lung diseases to save lives.

Now, this collaboration will help to do exactly that.

The approach taken by businesses within these industries must now change. With new legislation on exposure to harmful dust in Australia, new dust monitoring methods are needing to be implemented.

Aleks said “As an occupational hygiene-minded business we know only too well the devastating effects inhaling respirable dusts can have on people’s long-term health.”

“That’s why we’re invested in the success and distribution of new and effective real-time dust monitoring technologies such as the Trolex AIR XD Dust Monitor, the XD ONE Portable Dust Monitor and the AIR XS Silica Monitor. These are lifesaving technologies that need to be included in their safety thinking” stated Aleks further.

By using Trolex’s advanced dust monitoring technologies, small changes can have a huge impact.

As the war on silica dust grows ever stronger by the day, more needs to be done.

With the reduction in exposure limits coming into effect across Australia, particularly hard on respirable crystalline silica (RCS), real-time monitoring for silica dust is a necessity, retaining live data and providing an instant alarm the legislated threshold is breached.

Whilst the ability to retrospectively assess levels of silica dust in facilities is available to industries where deadly silica dust is prevalent, the ability to monitor for silica dust in real time is not.

Trolex’s all new real-time silica monitor, the AIR XS, allows for accurate and reliable results demonstrating compliance with legislation. Aleks commented on this world-first technology:

“We are really excited to be a part of this project to be able to detect silica in real time. This will be the world’s first monitor to have this capability and we’re proud to be distributing it throughout Australia. The project was produced with the support of the Centre for Work Health and Safety in NSW proving just how important and potentially life-saving the new technology will be.”

And with the talk of real-time, wearable silica monitoring devices a possibility in the future, of course it makes perfect sense for all industries to be increasingly focused on detection possibilities.

Together, Trolex and AES are providing real solutions for real problems in Australia.

If you’d like to speak to one of our experts about integrating real-time dust monitoring technology into your working environment, then you can use the contact form below to get in touch with one of our experts today.

Have you heard of the ‘psychological contract’? It’s the unwritten understanding of the interaction between you, your workplace environment and your colleagues.

We all have a psychological contract with our employers, whether we know it or not.

As well as considering the physical aspects of your work environment, your psychological contract includes things like the quality of relationships you have with the people you work with, whether you feel properly listened to and understood and know what’s expected of you in your role.

An important part of that contract is ‘psychological safety’. How safe or unsafe your psychological contract leaves you feeling at work.

A term coined in 1999 by organisational behavioural scientist, Amy Edmondson, ‘psychological safety’ includes things like trust in your colleagues, your perception of physical threat in your working environment and how you feel about the training and support you get to do your job.

Unsurprisingly, the safer people feel at work, both physically and emotionally, the more productive they are.

By the same token, if people feel unsafe, then not only are they less productive, but the time the trouble and expense of having to replace people unhappy in their jobs is huge.

Employee benefits provider Perkbox estimates that ‘disengaged employees are costing the UK economy £340 billion every year in lost training and recruitment costs, sick days, productivity, creativity and innovation.’

So how can you make sure that people in your organisation feel psychologically safe?

The first important step in creating a psychologically safe workplace is to make it as physically safe as possible.

Speaking with Trolex, Occupational Psychologist Catherine Dobson told us, “If an environment is not physically safe, if it’s too hot, too cold, or if it feels too dangerous people feel stressed. We must ask ourselves how do we get the right environment for people with the right kind of training, the right kind of cooperation to make it healthier?

Which is what contributes to making our range of dust monitors, such an important development. These include the AIR XD Dust Monitor, the XD ONE Portable Dust Monitor – our wearable dust monitoring technology, and our AIR XS Silica Monitor for real-time silica dust monitoring.

Not simply because it protects workers from the physical dangers of inhaling lethal respirable dusts, but because armed with the knowledge that they are working safely, people feel psychologically safer too.

Catherine explains how: “In relation to silica and dust monitoring. Because the AIR XS Silica Monitor is new, there’s scope for demonstrating that it works. And people can see that.

Also, because all these dust monitors work in real time, it gives people the trust that an intervention will take place should they be in danger. They can trust in the environment being safe.”

A very good thing for workers on both a physical and emotional level.

And great news, too, for the mining, tunnelling, quarrying, manufacturing and construction companies invested in fulfilling their side of the psychological contract with advanced dust monitoring.

Businesses can then reap the rewards of improved production and better worker retention, so everybody wins.