Real-time monitoring offers solutions to us in our everyday lives. Whether it’s the real-time alerts that tells you that you’re at risk or in danger, or the subsequent data which provides you accurate information on what you’re monitoring, real-time monitoring has become an essential part of our lives.

But what about real-time monitoring when it comes to enhancing the workforce? You’d rely on real-time monitoring and alarms to tell you there’s a fire in your home, so why wouldn’t you rely on real-time monitoring to tell you if you were a risk as serious to your health at work? You’d rely on real-time data to tell you if you needed to track nutrition or health trends, so why wouldn’t you rely on essential data in real-time in the workplace?

Whether it’s for the health and safety of you and your colleagues, to better understand the processes and efficiency of the business, or just to help aid decisions, real-time monitoring can provide valuable data to workforces across a whole range of industries. Whether you are monitoring for hazardous substances like dust or silica, or monitoring for HAV, sound levels or proximity measures, real-time monitoring can enhance your workforce.

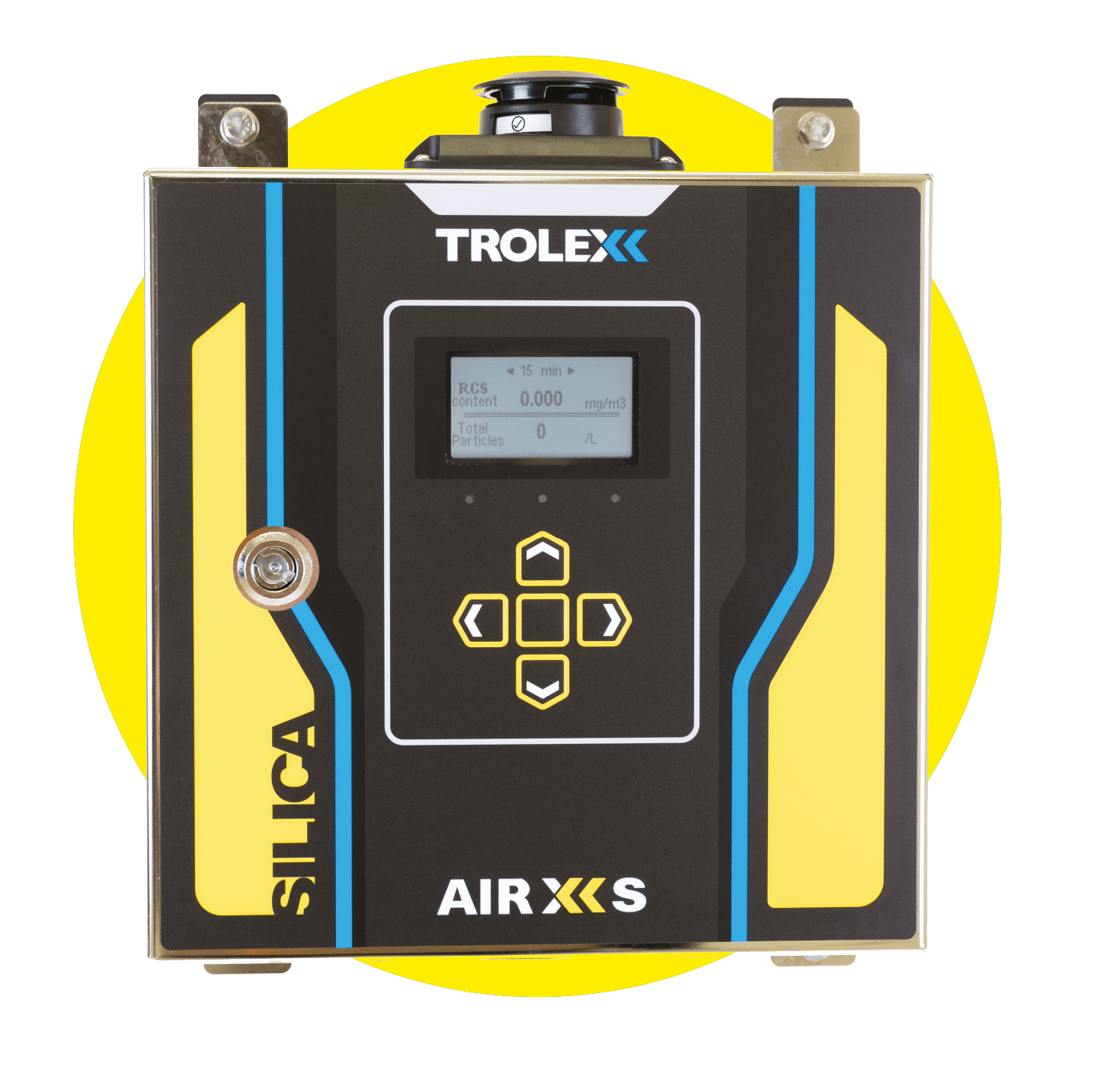

The AIR XS Silica Monitor leverages cutting-edge Optical Refraction Technology (ORT) to enhance workplace safety by providing real-time monitoring of respirable crystalline silica (RCS). Unlike traditional particle monitors, AIR XS distinguishes and measures RCS content, enabling immediate detection and response to harmful silica dust levels. This technology is crucial in combating occupational lung diseases such as silicosis, which affects millions of workers globally.

Current monitoring methods, like gravimetric sampling, are time-consuming and often deliver results too late to prevent exposure. In contrast, real-time silica monitoring offers immediate data, significantly reducing the risk of occupational silicosis by enabling prompt action to mitigate hazardous conditions. The importance of such real-time data is highlighted by cases like Joanna McNeill’s, who developed silicosis at the age of just 36. Her story, like many others underscores the necessity for continuous monitoring to protect workers from the threat of silicosis, regardless of their occupational environment.

Our real-time RCS monitor, AIR XS provides a real-time solution to this threat. Workers are not only alarmed and alerted when silica levels exceed legislative limits but can work to best practices by implementing AIR XS with the Hierarchy of Controls, supporting proactive measures to eliminate or minimise exposure to RCS. This move to real-time monitoring as a solution to the threat of silicosis has also been noticed by governing bodies, like the All-Party Parliamentary Group on Respiratory Health.

To learn more about how this real-time solution not only enhances worker safety but also streamlines business operations, click the link below to read the case study in full.

New test findings released, confirm the efficacy of a world-first real-time monitor for silica dust, which represents a revolution in the protection for workers exposed to respirable crystalline silica (RCS) dust.

As a leading workplace safety technology company, we have developed the AIR XS Silica Monitor, designed to protect workers against lung diseases such as silicosis by providing real-time readings of levels of crystalline silica in the air.

We have recently commissioned a leading occupational hygiene and laboratory testing organisation to conduct independent testing of the AIR XS. The results show the AIR XS repeatedly provided consistent, accurate, real-time data throughout an eight-hour testing period.

The testing demonstrates that AIR XS can improve worker safety by providing instant information to businesses and workers exposed to RCS, instead of having to wait up to four weeks to know their level of exposure to this killer dust, which is the current industry standard.

While the Australian Government recently implemented a ban on engineered stone, commencing 1 July 2024, the process most synonymous with creating silica dust, Group CEO Glyn Pierce-Jones said this ban alone would not solve the current health crisis caused by RCS.

“Silica dust is found in most building materials, so while banning engineered stone is a positive step, it’s not a holistic solution. The real issue facing the industry is the current archaic methods of testing for silica dust and the delay it causes in creating the safest possible workplace.”

The AIR XS is already being used in Australia to monitor RCS levels in many industrial locations.

Silica occurs naturally in soil, sand and granite; however, it is almost harmless in that state. Once those materials have been disturbed through construction or mining, silica dust is generated and can be inhaled into the lungs. This dust can cause silicosis, and other types of lung diseases and cancer, which are often irreversible and progressive.

Recent research from The Lung Foundation showed an estimated 600,000 Australian workers and between 40-50 million workers worldwide are exposed to silica dust across a wide range of industries including quarrying, construction, tunnelling, mining and many manufacturing processes.

The current approach to test for RCS is gravimetric sampling, the process requires collection, processing, and laboratory analysis of the sample, which is both time-consuming and costly for businesses. Direct-reading instruments offer businesses the ability to monitor employee safety on sites in real-time, eliminating the delays of weeks typically associated with potential RCS exposure.

Mr Pierce-Jones emphasised the urgent need for enhanced safety measures for anyone who may be in contact with silica.

“The current testing methodology for RCS only allows users to take an average reading over an eight-hour period and typically takes up to four weeks to produce a result,” Mr Pierce-Jones said.

“Our AIR XS Silica Monitor was designed to provide an accurate reading with immediate results, letting workers know when their health is in danger and allowing employers to respond in the most efficient manner.”

“These latest test results are another indicator of what we already knew at Trolex – that the AIR XS could be part of a desperately needed solution to an urgent health crisis.”

It’s estimated that over 40 million people worldwide are exposed to silica dust in the workplace. Respirable crystalline silica (RCS) contributes to one of the leading causes of death in the workplace, alongside other lung related illnesses. Due to this some of the industry’s most influential countries worldwide are making significant changes to regulations regarding silica exposure in the workplace.

In December 2023, Australia became the first country in the world to ban engineered stone due to rising cases of silicosis. From 1st July 2024, all use of engineered stone in Australia will be prohibited to protect workers from exposure to RCS in the workplace. Engineered stone is a manufactured material made from combining quartz or granite aggregates with resins and pigment and is a common material used in stone bench tops, often found in kitchens and bathrooms. It’s production often results in airborne RCS, leading to significant health risks to those working with it.

With reports that over half a million Australians are exposed to fine silica dust through stonemasonry and construction, figures suggest 103,000 of these workers are likely to be diagnosed with silicosis. The production and manufacturing of stone bench tops is a significant contributor to these statistics. The ban on engineered stone across the entirety of Australia is a step in the right direction to reduce the number of workers exposed to RCS and silicosis diagnosis in the future.

This ruling in Australia looks to have a set a precedent in influencing other countries to do the same. In May 2024, the first cases of silicosis linked to artificial stone countertops in the UK were reported, leading to calls for the material to be banned.

An estimated 600,000 workers are exposed to silica in the UK each year, and in Europe as a whole, 81% of those exposed are employed in construction or in manufacturing products used in the industry. After Australia became the first country worldwide to ban engineered stone in December 2023, UK kitchen company Herringbone announced they would also ban the sale of high-silica quartz worktop due to the risks posed to stonemasons.

Since speaking with their stonemasons about the risk of high quartz in engineered stone, Herringbone made the decision to become the first company in the UK to phase out the sale and production of engineered stone, as well as creating a petition to have the product completely banned in the UK, like in Australia.

In the US, the Biden administration has agreed to limit workers exposure to silica dust in mining, particularly when drilling for coal, ore and completing other mining operations. In April 2024, a ruling was announced to reduce the allowable silica dust levels in mining operations to 50 micrograms per cubic meter, with an action level at 25 micrograms, for an eight-hour workday.

The ruling will also update any respiratory protection standards for mining workers and in addition to silica dust, will also apply to diesel particulate matter and asbestos. The hope is that this will begin to reduce an estimated 1,067 deaths and 3,746 silica related illnesses in mining industries in the US and begin to make mining safer from the risk of RCS for the 55,000 American coal miners across the nation. The rule will come into action one year after its publication in April 2024.

With significant action being taken across major industries worldwide as of mid-2024 and onwards, protection for workers against respirable crystalline silica is becoming more of a high priority in workplaces. With banning of products known to produce dangerous levels of RCS, and with rule changes to limit exposure, workers short- and long-term lung health is becoming better protected than ever.

Launched in 2022, the AIR XS Silica Monitor isn’t like other silica monitors on the market. If you’ve been in the Health and Safety space, it’s likely you’ll know about Optical Particle Counter (OPC), also known as “light-scattering”; but our patented AIR XS isn’t just another OPC.

Unlike traditional Optical Particle Counters (OPCs) that rely on light scattering and interruptions to deduce particle size and quantity, the patented Optical Refraction Technology (ORT) used in the AIR XS shines a laser through each particle, capturing its refraction on multiple sensors.

In our blog below, we reference Pink Floyd’s 1973 album Dark Side of the Moon to explain one way to how ORT works. It’s not exact by any means but the refraction of the light coming out of the prism shows an example of how light refracts, similar to a crystalline particle.

Did you hear about the plane crash that killed everyone on board? Your answer likely depends on where you live.

According to researchers at the University of Oxford: ‘English Wikipedia readers were much more likely to read about North American and European crashes, and Spanish Wikipedia readers were more likely to read about Latin American crashes.

Page views on English and Spanish Wikipedia for North American and Latin American aircraft crashes, respectively, were each about 50 times greater than for African crashes.’

These events are tragic, to be sure, but the deaths from these situations are more generally heard about than others, such as from dust inhalation – despite technology and processes available to help prevent them.

It also depends on when the crash happened, with Royal Society Open Science discovering that irrespective of the crash location and body count, ‘on both English and Spanish Wikipedia, page views dropped in half between three to 10 days after the event’. The decay of novelty as we lose interest in things when they stop being new.

And then there’s how much capacity you have left to care, the concept scholars refer to as the ‘finite pool of worry’.

‘Because people have a limited capacity for how many issues they can worry about at once, as worry increases about one type of risk, concern about other risks may lessen.’ says The Centre for Research on Environmental Decisions.

Proximity. Timing. The competition with other concerns for a limited capacity to impact emotions. It’s a complicated old business. Disaster, its impact, its legacy and even the ways we look at – or away – from it. That’s only talking about sudden disastrous events; the plane crash, typhoon, earthquake, and other similar events.

What about the disaster that inexorably unfolds? The slow-motion cumulative disaster. Disaster that – over time – takes far more lives than the one off tragedies? Or even a succession of one-off tragedies?

What about:

As we’ve seen, it’s human nature to focus on more recent, local, high-profile events. Discreet, distinct, storylines.

However, don’t the disasters we overlook – the slower moving, less attention-grabbing tragedies that play out day after day – deserve our attention too?

The problem of particulate and dust inhalation is widely ignored, so too is the priority in finding viable solutions.

This is why we do what we do at Trolex, and why we’ve set ourselves the challenge of reducing the risk and impact dust inhalation can have on workers around the world who are rarely spoken about.

This is done through the development of technology like the AIR XD Dust Monitor, XD ONE Portable Dust Monitor, XD1+ Personal Dust Monitor and AIR XS Silica Monitor alongside supporting software, to deliver data in realtime and make sure every worker knows the state of air around them.

We haven’t stopped there, however. Our engineers are constantly asking “what can we do so that, in 10 years time, every worker in the world exposed to dangerous particulates is wearing personal dust monitoring?”

This is easier said than done, of course, but it’s a challenge we’re committed to undertaking and beating. As well as setting ourselves the task of overcoming the engineering challenge, we’re having to face those natural ‘hidden in plain sight’ biases discussed above.

We’ve privately funded each project every step of the way – from research and development, to manufacturing and distribution. Every penny.

Not that we mind. In fact, we’re proud to have independently conceived and created our range of real-time dust monitoring products: innovative dust monitoring technology that’s now the envy of the industry.

These products are perfectly capable of helping us meet our 10-year challenge, and in the process save many thousands of lives.

Set against the backdrop of Covid-19 and the billions and billions of pounds spent to combat it, the macabre irony hasn’t been lost on us, that worldwide more people have died inhaling dangerous particulates in the last five years than they have from Covid 19.

Unnecessary deaths that for only a couple of million pounds backing, our technology could still go faster and further in preventing.

Maybe we should call for a lockdown?

We work with businesses around the world to improve the safety of hazardous work environments and give workers a better chance at reducing the risks of dust inhalation. The long term effects can be severe and, while it might not be as obvious or attention grabbing as other tragedies, we’re committed to doing what we can to help those at risk.

If you’d like to know more about our dust monitoring systems and how they can help your worksite, get in touch with our team of experts today.

We’re living through an air pollution emergency. One that’s already claiming thousands of lives and costing billions of pounds. And that news shouldn’t come as a surprise.

We wrote in a recent blog, The threat from particulates: It gets worse about an American academic study: “Long-Term Exposure to Fine Particulate Matter, Residential Proximity to Major Roads and Measures of Brain Structure.”

The report clearly shows the risks that people living over extended periods near busy main roads face from fine dust that causes respiratory diseases, results in brain atrophy (brain shrinkage) and leads to an increased risk of stroke and other disease.

Another academic paper, ‘Air Pollution and Noncommunicable Diseases’ suggests that air pollution may be damaging ‘every organ in the body.’

Unfortunately there was nothing ‘academic’ about the consequences of particulate inhalation for nine year old Ella Kissi-Debrah, whose death in 2013 was caused by ‘acute respiratory failure, severe asthma and air pollution exposure’.

“The whole of Ella’s life was lived in close proximity to highly polluting roads. I have no difficulty in concluding that her personal exposure to nitrogen dioxide and PM was very high,” stated the coroner.

And the really sad thing about Ella and her family’s suffering?

Is that it’s far from unusual.

According to the World Health Organisation, air pollution is the “new tobacco”, killing 7 million people a year and harming billions more.

“No one, rich or poor, can escape air pollution. It is a silent public health emergency.” Dr Tedros Adhanom Ghebreyesus, the WHO’s director general.

More than nine in ten people breathe toxic air and 300 million live where toxic fumes are six times above international guidelines and the health impacts are profound – especially for children.

So what’s going on? How is it possible that so many people suffer so much through filthy, contaminated air?

A rush for profits? For progress? For economic advancement? A lack of technology? Insufficient knowledge? Clarity of thought? Understanding? Will? A short-termism that prioritised wealth over health?

In truth it’s all these factors and more. Reasons, more often excuses, that in the not so distant future people will look back at in horror. A situation where people simply won’t believe that things were allowed to get so bad and stay so bad for so long.

Thankfully, though belatedly, the weight of detailed research, visible interventions from the likes of WHO, an increasingly active green movement and high profile tragedies such as the death of Ella Kissi-Debrah are seeing attention at last turning to the issue of air pollution and how best to tackle it.

So much so that the language of particulates and respiratory health is even entering mainstream use. The government responded to Ella Kissi-Debrah’s death with, “We are delivering a £3.8 billion plan to clean up transport and tackle NO2 pollution, and going further in protecting communities from air pollution, particularly PM2.5 pollution, which we know is particularly harmful to people’s health.’

Which is great.

But while a public recognition of the issue and an ability to deploy the right words in addressing the issue is a positive sign, it’s the ability of governments and industry to actually do something about air pollution that really matters. Action that all of us will be judged on in the future.

Signs are mixed. For example, despite the UK Government’s recognition that we all need to be protected from toxic air, and despite pledging funds to fight that cause, it has so far voted against proposals to put WHO pollution limits into UK law, arguing that they’re ‘uneconomical.’

‘Were you part of the problem or part of the solution?’ we’ll all be asked in the not too distant future.

Which is why we do what we do here at Trolex – to be a very proud and purposeful part of the solution.

Enquire today about our new AIR XD Dust Monitor and XD ONE Portable Dust Monitor in our real-time dust monitoring range – accurate, simple to use, easy to maintain, real-time particulate detection technology that keeps people safe.

The IOSH Construction Group Committee Construction Dust Survey makes for sobering reading. Firstly, it highlights the fact that much more needs to be done to increase awareness of the dangers of dust from an employees perspective:

“Dust causes a lower level of concern among employees than the more immediately noticeable dangers of construction, such as falls…they do not perceive it as a significant immediate risk to their wellbeing unlike falls from height, equipment etc.”

It also highlights a lack of awareness from the industry as a whole. Of 618 health and safety professional respondents, ‘44.6 percent thought that the industry gave little or no priority to the issue, and a similar proportion (42.4 percent) felt that it received the same priority as other health issues.’

And even when awareness exists, the report found that compliance is weak.

‘54.0 percent of respondents indicated that workers sometimes fail to follow prescribed methods of work. Over a third of respondents (36.2 percent) indicated that this happened most or all of the time.’

So what’s going on? Why, even when employers and their onsite teams are in possession of the facts, do they too often choose to ignore the dangers posed by dust?

Dangers that lead to 10 deaths a week from lung cancer caused by silica dust, let alone the other illness and premature death from other cancers, silicosis, asthma and chronic obstructive pulmonary disorder (COPD).

You’ll be familiar with the concept of cognitive dissonance, ‘the state of discomfort felt when two or more modes of thought contradict each other’.

Like knowing smoking is bad for you, but continuing to smoke.

Like, “we know dust is dangerous but there’s no convenient, low-cost alternative to handling the risk. So we’ll stick with what we’ve always done.”

Barriers to change

There’s a lot to learn in the Construction Dust Survey.

More than anything, it’s highlighted that despite being increasingly aware of the dangers, people aren’t taking action.

Somehow, industry has convinced itself that the culture and adoption of, the management of, and the cost, complication and general hassle of creating a safe working environment is more trouble than just leaving things be.

Here are just some of the barriers to change noted in the survey:

Culture: The culture of the industry, and its ‘traditional’ view of dust as an expected or normal part of construction work, can be a significant barrier.

Use: Workers often view the controls as cumbersome, impractical, affected by poor maintenance or giving rise to other risks. This deters use.

Employees: Implementing controls effectively depends on good management and supervision. Operators generally choose not to use controls.

Management arrangements: In general, the industry does not seem to manage dust control issues adequately. Comments refer to a link between the management priority given to this issue and the corresponding conditions found on-site.

Cost: Dust control is often viewed as labour-intensive, expensive, time-consuming and a nuisance that slows work.

‘The industry creates this risk. It now needs to acknowledge it, own it and deal with it.’

It somehow seems that as awareness increases, industry seems to think a cultural shift towards safer working environments will run its own natural course over time.

“It is like wearing a hi-vis 15 years ago or hard hats. It took years for the culture to change.” says a contributor to the report.

Fortunately, we’ve taken a far more proactive approach.

What if we could fast track that safer working environment?

What if that cognitive dissonance could be eased instantly and increased awareness could be achieved overnight? And what if you only ever had to use dust control methods when you actually needed them?

It’s hard to not be aware of something when an alarm is screaming in your ears and bright lights are flashing.

Well, here’s the thing.

A low-cost, simple-to-use, personal alarm would help solve the problem overnight.

All those adoption and implementation objections, all the excuses and all those barriers to change would evaporate. Instantly.

And here’s another thing.

That low-cost, simple-to-use, personal alarm exists.

It’s new and it’s here.

The XD ONE Portable Dust Monitor.

Get in touch today and we’ll tell you everything you need to know about how real-time dust and silica monitoring technology can protect your workers from the threat of preventable disease.