‘PM’ or particulate matter, also known as particle pollution is the term for a mixture of solid particles and liquid droplets found in the air.

It’s estimated that air pollution is linked to 43,000 deaths per year in the UK. Worldwide, at least 7 million people die each year from exposure to air pollution, with 91% of the worldwide population living in locations where the air quality exceeded the World Health Organisations (WHO) air pollution guidelines.

These guidelines state that that annual average concentrations of PM2.5 should not exceed 5 µg/m3 and PM10 should not exceed 15 µg/m3 (both for 24-hour periods). According to the WHO, ‘fine particulate matter at PM2.5 can penetrate through the lungs and further enter the body through the blood stream, affecting all major organs’. Exposure to dust at PM2.5 can cause serious disease to the respiratory system, such as lung cancer and COPD, and also can effect cardiovascular diseases, such as a stroke.

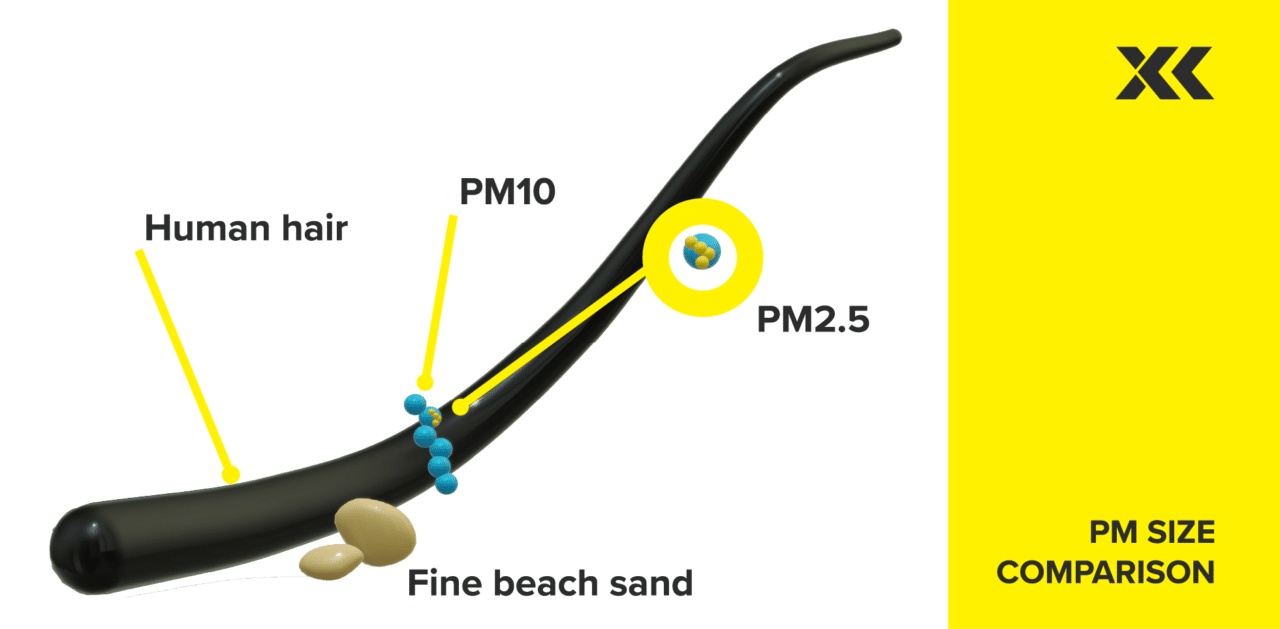

The image below demonstrates PM2.5 and PM10 size in comparison to a single human hair and a grain of sand.

The Department for Environment Food & Rural Affairs (DEFRA), the UK government ministerial department for environment protection, have also highlighted the severity of exposure to air pollution. This growing concern for the UK government estimated in 2010 that the cost of health impacts of air pollution was likely to exceed estimates of £8bn to £20bn.

Although between 2005 and 2022, the UK’s PM2.5 emissions decreased by 41%, emission levels have been relatively steady with small annual fluctuations in the last decade. Industrial combustion is a major source of PM emissions, as well as emissions from industrial production also playing a major part, which can be linked to heavy-dust industry where hazardous particulates can become airborne. Despite some reductions in PM emissions, the threat still very much remains.

A solution to this is real-time dust monitoring. Real-time particulate monitoring allows people in heavy dust loading environments, including industrial applications, to not only understand, but alert them instantaneously when they are exposed to dangerous levels of air pollution. For example, our AIR XD Dust Monitor can alert people in real-time when legislative levels of µg/m3 are breached, over a time-weighted average (TWA) 8-hour period, for both PM2.5 and PM10.

This technology not only offers a simple solution to individuals at high risk of exposure to air pollution by providing instant alerts, but also can help to prevent exposure in the future, as at-risk individuals can learn exactly when and where exposure to air pollution is highest and will likely occur. Thanks to real-time monitoring, both in the UK and Worldwide, we can reduce exposure to air pollution.

New test findings released, confirm the efficacy of a world-first real-time monitor for silica dust, which represents a revolution in the protection for workers exposed to respirable crystalline silica (RCS) dust.

As a leading workplace safety technology company, we have developed the AIR XS Silica Monitor, designed to protect workers against lung diseases such as silicosis by providing real-time readings of levels of crystalline silica in the air.

We have recently commissioned a leading occupational hygiene and laboratory testing organisation to conduct independent testing of the AIR XS. The results show the AIR XS repeatedly provided consistent, accurate, real-time data throughout an eight-hour testing period.

The testing demonstrates that AIR XS can improve worker safety by providing instant information to businesses and workers exposed to RCS, instead of having to wait up to four weeks to know their level of exposure to this killer dust, which is the current industry standard.

While the Australian Government recently implemented a ban on engineered stone, commencing 1 July 2024, the process most synonymous with creating silica dust, Group CEO Glyn Pierce-Jones said this ban alone would not solve the current health crisis caused by RCS.

“Silica dust is found in most building materials, so while banning engineered stone is a positive step, it’s not a holistic solution. The real issue facing the industry is the current archaic methods of testing for silica dust and the delay it causes in creating the safest possible workplace.”

The AIR XS is already being used in Australia to monitor RCS levels in many industrial locations.

Silica occurs naturally in soil, sand and granite; however, it is almost harmless in that state. Once those materials have been disturbed through construction or mining, silica dust is generated and can be inhaled into the lungs. This dust can cause silicosis, and other types of lung diseases and cancer, which are often irreversible and progressive.

Recent research from The Lung Foundation showed an estimated 600,000 Australian workers and between 40-50 million workers worldwide are exposed to silica dust across a wide range of industries including quarrying, construction, tunnelling, mining and many manufacturing processes.

The current approach to test for RCS is gravimetric sampling, the process requires collection, processing, and laboratory analysis of the sample, which is both time-consuming and costly for businesses. Direct-reading instruments offer businesses the ability to monitor employee safety on sites in real-time, eliminating the delays of weeks typically associated with potential RCS exposure.

Mr Pierce-Jones emphasised the urgent need for enhanced safety measures for anyone who may be in contact with silica.

“The current testing methodology for RCS only allows users to take an average reading over an eight-hour period and typically takes up to four weeks to produce a result,” Mr Pierce-Jones said.

“Our AIR XS Silica Monitor was designed to provide an accurate reading with immediate results, letting workers know when their health is in danger and allowing employers to respond in the most efficient manner.”

“These latest test results are another indicator of what we already knew at Trolex – that the AIR XS could be part of a desperately needed solution to an urgent health crisis.”

Our AIR XS Silica Monitor, an innovative real-time respirable silica (RCS) monitoring device, has been deployed at a major railway operations project to monitor the levels of RCS which workers may be exposed to.

The Central Rail Systems Alliance (CRSA), an alliance between Network Rail, Balfour Beatty, AtkinsRéalis and TSO have been using an AIR XS unit to monitor the levels of RCS released when damaged rail tracks are replaced; when rail track is damaged or needs replacing, the ballast surrounding the track is disturbed and can release RCS. The AIR XS unit was supplied by our UK partners Sunbelt UK & Ireland.

The challenge faced by CRSA was to measure the level of RCS and accompanying dust being released into the atmosphere during the unearthing process of 425m rail and ascertain the level of risk associated for those working in the immediate and surrounding environments. The AIR XS unit was manoeuvred around the site in-line with project progress, so that working scenarios can be accurately represented in the data set.

Upon conclusion of the project, Madeline Dunn, the Health and Safety Advisor for CRSA praised the monitoring and recording capabilities of the AIR XS, saying “We have completed trials prior, however this is the only unit where it is measuring silica and not just general dust levels. We gained the knowledge that the exposure levels were actually higher than we anticipated with even low-level ballast disturbance.”

Thanks to the team at Sunbelt Rentals UK & Ireland for the in-depth case study which you can read in full here.

In this exclusive interview with Trolex, Gordon Sommerville shares his first-hand experience of the dangers of silica exposure and what you can do to protect yourself and others from the dangers of silica dust.

“The only cure for dusty diseases at the moment is not to let dust get inside the body, which means in order for silica induced diseases to be classed as 100% preventable, awareness of the hazard throughout the exposed population is required.”

Gordon, now a retired stonemason, was diagnosed with silicosis in 2015. He started his career working in the construction industry after leaving school in 1976 and soon became a stonemason and builder to trade. In such an environment, working on projects both large and small throughout his career, dust was everywhere.

“No matter what type of work I was carrying out or who I was working for, daily dust was involved — and lots of it. I did not realise dust was making me ill but during my career there were little clues which should have raised a red flag.”

Gordon’s aim in sharing his story is to inform, educate and highlight the dangers of exposure to silica dust and to give advice to individuals who work in similar industries on how to avoid the issues that he now faces as a result of silicosis.

New studies from charity ‘Asthma and Lung UK’ (ALUK) found that lung disease deaths in the UK are the highest in Western Europe.

The staggering statistics have prompted an expanded approach towards research and development of lung diseases from ALUK.

ALUK’s studies show that cases of lung disease related deaths in the UK have been on the rise for the past 20 years.

It is reported that 500,000 people in the UK died from deaths relating to lung diseases over a seven-year period.

In 2018 alone, 84,721 respiratory deaths were recorded in the UK.

The charity has described the state of lung health in the UK as ‘shameful’, stating the need for improved research and development solutions to the problem.

After its relaunch in February, ALUK established a new five-year strategy upon the results of the study.

Lung diseases are currently the third most common cause of death in the UK and it’s currently costing the NHS £9 billion every year.

Despite this, lung-related health care is receiving less than 2% of public funding.

It is evident that the seriousness of lung problems in relation to other diseases is not taken as seriously, despite what we are seeing from the data.

A predominant factor in the poor state of the nation’s lung health is that people believe lung conditions aren’t life-threatening. This is a major misconception.

Through spreading awareness of how ‘shameful’ lung health is in the UK, this misconception can be dispelled.

ALUK aim to reduce lung disease deaths by 20% by 2027. When making everyone aware of these gruesome statistics, this can become a possibility.

The end goal is to provide support for everyone effected by all forms of lung disease.

ALUK’s solution to achieving this goal is through research and innovation.

Their aim is to expand their research and innovation programme so that £5 million is being invested into relevant research each year.

With the aim to “develop at least three new self-management tools” for 2 million people suffering with lung diseases, ALUK want to make training programmes and essential advice easily accessible to those who need it.

“By 2027, we will give 80% of people with lung conditions the opportunity to access our network of Breathe Easy support groups” states the ALUK Strategy to 2027.

With this, the strain on public healthcare is minimised and individuals are able to monitor their personal health through digitalised platforms and shared networks.

The statistics right now make for harrowing reading and harsh truths.

However, for ALUK, research and innovation is the solution for the future. By identifying the problem and acknowledging its severity and scale, goals can be achieved.

Through effective research and innovation lung disease deaths can become a thing of the past, not just in the UK, but worldwide.

Trolex are excited to be partnered with Active Environmental Solutions (AES), working together to protect workers from the dangerous and often irreversible consequences of occupational lung diseases caused by dust inhalation.

With AES’s specialist knowledge of occupational health and safety in Australian industries and Trolex’s leading safety technology, the opportunity of delivering solutions to prevent the dangers of dust inhalation for Australian workers, is not just a possibility, but now a reality.

AES want to spread awareness of the dangers of occupational lung diseases caused by dust inhalation. And in the case of dust monitoring, spreading awareness that new real-time dust monitoring technology to help prevent lethal occupational respiratory diseases now exists.

The opportunity to partner with Trolex was welcomed by AES, as it means that they can merge their expertise in occupational health using Trolex’s leading safety technology.

This creates the best solutions to their respective industries.

This simple message appealed to AES, and to Aleks Todorovic MSc, (OHP), Managing Director of AES’s team of Australian Occupational Safety experts at AES, as it aligned perfectly with the workers they seek to protect:

“Many businesses intuitively know the benefit of a broad threat detection – they just don’t know they know it, or perhaps how they go about implementing such devices – it’s our job to awaken that knowledge and show them there are new and effective dust detection technologies such as the Trolex AIR XD Dust Monitor, the XD ONE Personal Dust Monitor and most recently, the AIR XS Silica Monitor.

There are no arm twisting, or heavy sales techniques involved. Just a clear and simple presentation of responding to the facts.

Which is why Trolex and AES are working hard to provide further education to Australia’s mining, tunnelling, quarrying and construction industries, where workers are exposed to dangerous forms of respirable dusts.

This common goal of providing and expert knowledge and specialist equipment to these industries is the drive needed to inevitably reduce instances of occupational lung diseases to save lives.

Now, this collaboration will help to do exactly that.

The approach taken by businesses within these industries must now change. With new legislation on exposure to harmful dust in Australia, new dust monitoring methods are needing to be implemented.

Aleks said “As an occupational hygiene-minded business we know only too well the devastating effects inhaling respirable dusts can have on people’s long-term health.”

“That’s why we’re invested in the success and distribution of new and effective real-time dust monitoring technologies such as the Trolex AIR XD Dust Monitor, the XD ONE Portable Dust Monitor and the AIR XS Silica Monitor. These are lifesaving technologies that need to be included in their safety thinking” stated Aleks further.

By using Trolex’s advanced dust monitoring technologies, small changes can have a huge impact.

As the war on silica dust grows ever stronger by the day, more needs to be done.

With the reduction in exposure limits coming into effect across Australia, particularly hard on respirable crystalline silica (RCS), real-time monitoring for silica dust is a necessity, retaining live data and providing an instant alarm the legislated threshold is breached.

Whilst the ability to retrospectively assess levels of silica dust in facilities is available to industries where deadly silica dust is prevalent, the ability to monitor for silica dust in real time is not.

Trolex’s all new real-time silica monitor, the AIR XS, allows for accurate and reliable results demonstrating compliance with legislation. Aleks commented on this world-first technology:

“We are really excited to be a part of this project to be able to detect silica in real time. This will be the world’s first monitor to have this capability and we’re proud to be distributing it throughout Australia. The project was produced with the support of the Centre for Work Health and Safety in NSW proving just how important and potentially life-saving the new technology will be.”

And with the talk of real-time, wearable silica monitoring devices a possibility in the future, of course it makes perfect sense for all industries to be increasingly focused on detection possibilities.

Together, Trolex and AES are providing real solutions for real problems in Australia.

If you’d like to speak to one of our experts about integrating real-time dust monitoring technology into your working environment, then you can use the contact form below to get in touch with one of our experts today.

Working with distributors and partners overseas is how we gain exclusive access to the businesses that need our products to save the lives of their employees.

We value our close partners as much as our own employees and have good relationships that last way beyond the business transaction. This includes trusting our partners to demonstrate our new technology to their customers, in mutual understanding, so our partners and their customers can get ‘up close and personal’ to our XD ONE Portable Dust Monitor and can try it out for themselves in a real-life environment.

Our Belgium, Netherlands and Luxemburg (BeNeLux) distributor, BASystemen, ordered six XD ONE demo units to give to their customers to trial. They landed a few days ago, and their directors are already behind our campaign to get these monitors into the hands of every worker who needs one, and to start saving lives straight away.

Khoa Nguyen is a keen advocate of field trails, and comments ‘we love feedback!’ He intends to lend them out to his customers so they can ‘try out all functionalities’.

The dust monitors themselves have been met with great praise and Khoa says, ‘We truly believe that the XD ONE Portable Dust Monitor is a nice solution to the market needs for a portable dust monitor, which is simple to use, reliable and cost effective’. He adds, “…size is great, weight is perfect and very easy to use.”

Khoa is happy with our partnership, and concludes by saying, “Response is quick and partner conditions are good so both parties benefit long term” and suggests that as a company, BASystemen can “definitely learn from this.”

If you’re a distributor and would like to request demo units of the XD ONE Portable Dust Monitor, please get in touch today.

A sign of things to come.

Despite the protests of Johnson and Johnson, who played the indignation card at a “fundamentally flawed trial, grounded in a faulty presentation of the facts.”

The verdict is “[at] odds with decades of independent scientific evaluations confirming Johnson’s Baby Powder is safe, does not contain asbestos and does not cause cancer,” they quibble.

$2.12 billion in damages tells another story.

That’s what a Missouri court ordered Johnson and Johnson pay to women suffering ovarian cancer caused by asbestos in its baby powder and other talc products. Litigation that looks like just the beginning.

Not just for Johnson and Johnson, who now face‘21,800 lawsuits claiming that its talc products cause cancer because of contamination from asbestos, a known carcinogen,’ but also for the many employers the world over who fail to properly protect their workers from preventable disease.

Sarah Jardine, HSE’s chief inspector of construction says: “Around 100 times as many workers die from diseases caused or made worse by their work than are actually killed in construction accidents.”

In the UK alone, 14,000 people a year die prematurely from largely preventable disease caused by the inhalation of respirable dust in the workplace.

Preventable because there’s no excuse for remaining ignorant of the potentially fatal consequences of exposure to dangerous microscopic airborne dust particles.

While lack of awareness has certainly been a problem in the past, now, with plenty of readily available research, public health messaging and examples of high-profile litigation, there’s simply no reason for companies to ignore their responsibilities,

Especially following new advances in dust measurement technology.

So not only is ignorance (still) an illegitimate excuse, with new real-time dust monitoring technology that provides you and your workers with real time and highly accurate dust readings in any working environment, so, too, is blaming a lack of suitable technology.

Put simply, if you’re serious about running a business you need to be serious about protecting people from the dangers of dust inhalation that surround them. Serious about both understanding those dangers and then putting the measures in place to mitigate them.

And as if the moral obligation wasn’t enough, the commercial implications are enormous, too; as Johnson and Johnson are discovering.

There’s more to worry about than the obvious bottom line legal costs and compensation. You need to consider the reputation costs in the form of lost business opportunities and even share price, insurance premium hikes, loss of production or reduced output, sickness cover and pay, and the lack of future legal and financial protections. All the many, undesirable and inevitable consequences of being exposed as negligent. The last thing any business needs or wants.

Are you still unclear about the extensive danger of dust? Or do you already realise the danger, want to do something about it but are unsure how real-time dust monitoring technology can help you?

Either way feel free to get in touch. We’ll tell you the many ways that we help businesses across all sorts of sectors, all over the world. Everything you need to know about protecting your workers from the threat of disease, and your business from the threat of litigation. And all its damaging implications.