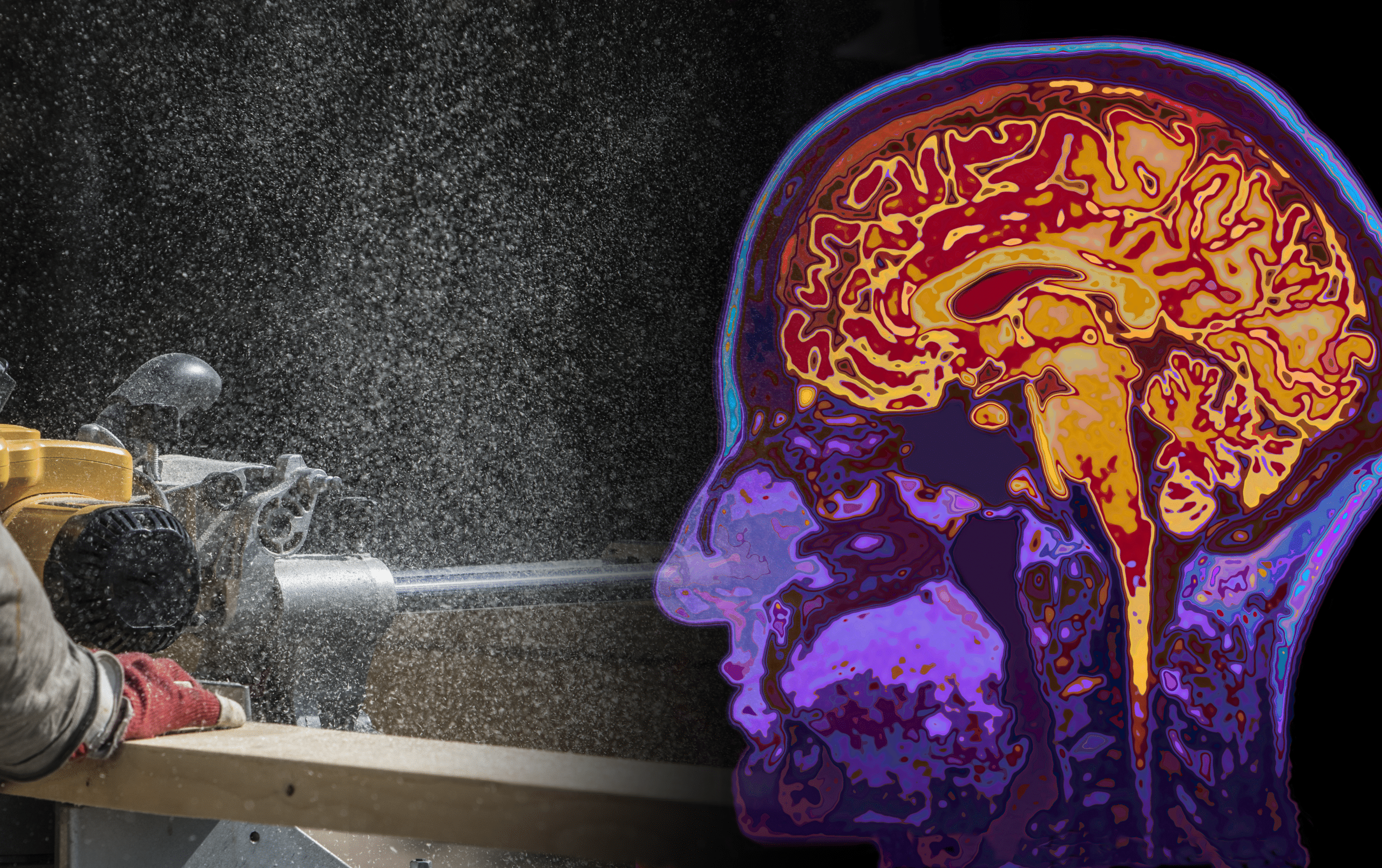

With an estimated 1 million people dying globally from the inhalation of dust in occupational environments every year, now is the time to protect your workers. Real-time dust and silica monitoring provides instant alarms and alerts for all workers at risk of dangerous dusk regardless of their application, processes or industry.

We’re continuously innovating real-time dust monitoring technology to give you access to the information to effect change and keep your workers safe from hazardous respirable dusts. With a range of dust and silica monitoring options, we’re here to help you protect your workers.

Whether that’s heavy-duty area monitoring for high dust loading environments, personal dust monitoring for individual monitoring needs, or silica monitoring for working environments with high respirable crystalline silica (RCS) content, such as stonemasonry, tunnelling or quarrying.

Real-time monitoring offers solutions to us in our everyday lives. Whether it’s the real-time alerts that tells you that you’re at risk or in danger, or the subsequent data which provides you accurate information on what you’re monitoring, real-time monitoring has become an essential part of our lives.

But what about real-time monitoring when it comes to enhancing the workforce? You’d rely on real-time monitoring and alarms to tell you there’s a fire in your home, so why wouldn’t you rely on real-time monitoring to tell you if you were a risk as serious to your health at work? You’d rely on real-time data to tell you if you needed to track nutrition or health trends, so why wouldn’t you rely on essential data in real-time in the workplace?

Whether it’s for the health and safety of you and your colleagues, to better understand the processes and efficiency of the business, or just to help aid decisions, real-time monitoring can provide valuable data to workforces across a whole range of industries. Whether you are monitoring for hazardous substances like dust or silica, or monitoring for HAV, sound levels or proximity measures, real-time monitoring can enhance your workforce.

We’re excited to bring to the market our XD1+ Personal Dust Monitor as a connected dust monitor with the Reactec Ecosystem.

The Reactec Ecosystem for workplace exposure to hazards includes an IoT gateway, Reactec’s workplace wearable RASOR for secure data transmission, an RFID identity card to personalise the collected dust data and the cloud-based Reactec Analytics software for informative and automatic data dissemination.

RASOR is a communications gateway with integrated SIM and GPS technology to gather data seamlessly from the XD1+ and present it live, personalised and position tracked data to remote line managers via a browser.

Our XD1+ Personal Dust Monitor can be easily connected with RASOR in two different modes for both single worker use and for pairing a number of XD1+ devices to a RASOR connected in hub mode, allowing for flexibility when working, but still providing vital information of worker exposure which can be analysed and interrogated on Reactec’s Analytics platform.

By leveraging revolutionary real-time personal monitoring technology with location tracking, automatic data collection and powerful data analytics, employers can now control their worker’s exposure to harmful respirable dust like never before and reduce these occupational diseases thanks to connected XD1+ and Reactec Ecosystem.

Check our guide for details on the key modes of pairing XD1+ with the Reactec Ecosystem, a run-through of how to connect your XD1+ in these different modes and the benefits of each type of connectivity.

A manufacturer of prestigious natural stone, Burlington Stone have quarried for over 200 years across the English Lake District, extracting and crafting a diverse range of signature British natural slate and stone products.

Individuals across their workforce are often exposed to hazardous substances, most notably airborne dust, including silica dust. Burlington Stone trialed two XD1+ devices on their site for a month to see how real-time, personal dust monitoring would improve their safety processes.

After the trial, we spoke to Health and Safety Manager, Peter Walker, about the success of the trial and some of the major benefits which Burlington Stone’s workforce found deploying XD1+ Personal Dust Monitor units in their day-to-day processes.

You may have seen The All Party Parliamentary Group (APPG) for Respiratory Health report ‘Silica – the next asbestos’ released in March 2020?

In it, it states:

“Construction workers are still 100 times more likely to die from a preventable occupational disease than from an accident. We also know that approximately 12,000 deaths in the industry each year are linked to exposure to dust and chemicals.”

“Figures from IOSH show that roughly half a million people are exposed to RCS at work in the UK. They estimate that in Europe as a whole, 81% of these are employed in construction or in manufacturing products used in that industry.”

Experts at Trolex brought our new technology to the APPG’s attention and explained our nine-year silica detection R&D project that resulted in development of the new real-time silica monitor – work that we’d kept closely under wraps until mid 2021.

The original report refers to Workplace Exposure Limits (WELs) of dust. It says:

“Dust monitoring is vital. Technology advances mean that new methods of real-time exposure level monitoring are now possible. Knowing what the actual exposure levels are is important as exposure will depend on the actual task (e.g. cutting concrete is higher risk than breaking concrete, and the actual exposures depend on the concrete mixture).

“The new Code of Practice for Tunnelling […] that requires the use of new technology which is just becoming available and gives an instantaneous measurement.”

The instantaneous measurement the report refers to is the measurement of a variety of dust and particulates (something we already do with our AIR XD Dust Monitor and XD One Portable Dust Monitor, XD1+ Personal Dust Monitor products) – not specifically silica. Silica always being too difficult to uniquely identify.

Until now.

Our new silica-specific monitoring technology is a game changer.

By working with the authors of the APPG to share the features, benefits and thinking behind the new real-time silica monitoring technology they’ve been able to update the report with new advice on how to best protect workers from the dangers of respirable crystalline silica (RCS).

Congratulations to the New South Wales Government for the foresight and resolution in driving through new legislation to protect workers from the hazards of silica, coal dust, and diesel particulates.

Speaking to Australian Mining, the state’s Deputy Premier and Minister responsible for resources John Barilaro said, “The decision to fast-track these more stringent standards for coal dust exposure was an easy one and is a great example of mine workers, mine operators and government working together to ensure we have robust frameworks in place to address this insidious disease.”

The legislation, which took effect from July 1st 2021, is hugely ambitious too. The legal exposure limit to respirable coal dust was reduced from 2.5 to 1.5 mg/m³ and respirable crystalline silica from 0.1 to 0.05 mg/m³. A new diesel exposure standard of 0.1 mg/m³ commenced 1 February 2021.

Compare the New South Wales Government’s to recent legislation in other parts of the world, and you can see how progressive the New South Wales Government has been. For example, in the United States where OSHA reduced the respirable crystalline silica permissible exposure limit (PEL) affecting the construction, manufacturing, and fracking industries from an allowable average of 250 micrograms per cubic meter of air over an eight-hour shift to 50 micrograms per cubic meter.

In the UK, respirable crystalline silica (RCS) control measures need only be effective in keeping exposure below the Workplace Exposure Limit (WEL) at the old NSW level of 0.1 mg/m³ respirable dust, averaged over eight hours.

With efforts underway to determine whether these levels might be made even more stringent, the good work is clearly an ongoing priority.

As The New South Wales Resources Regulator says in its compliance priority January-June 2021 report. ‘With the implementation of the revised exposure standards for silica and respirable dust, and a new exposure standard for diesel exhaust emissions, airborne contaminants was a priority project between July and December in 2020 and will continue to be a focus area.’

But it’s one thing to bring new, more stringent particulate exposure regulations onto the statute book. It’s another matter altogether making sure they are adhered to.

For a start, guidance needs to be shared with business owners and operators to help them properly implement effective health control plans in the context of the new regulations.

And what about the technical implications? With legal limits (quite rightly) ever shrinking, how can businesses be absolutely confident that the technology they use onsite to measure exposure to harmful dust and particulates is accurate, realistically deployable and affordable?

With much of the legacy technology on the market anything but accurate, realistically deployable and affordable, clearly the challenge for technology companies is to step up and find new ways for industry to meet these new standards.

At Trolex we’ve been working tirelessly on meeting these challenges for years.

And now we have.

It’s called the Trolex real-time dust monitoring range of fixed and wearable dust monitors.

You might also call it an overnight 40-year success story, as we’ve turned our vast experience in environmental monitoring in mining and tunnelling, to designing, manufacturing and distributing world leading dust and particulate monitoring technology.

The Trolex AIR XD Dust Monitor and XD ONE Portable Dust Monitor are both designed to detect even the finest of particulates.

Fixed and wearable, real-time analysis of your working environment from the Trolex dust monitoring range giving you a crystal clear understanding of the real particulate threat you face.

Simple to deploy, easy to maintain and super accurate they deliver a practical and affordable way of protecting your workers AND remaining within the law.

Now, whatever the new legislation and however strictly it’s applied, you can be absolutely sure that you have the technology in place to meet all legal and regulatory responsibilities as well as lead a healthy, happy, motivated workforce.

Don’t take chances. Contact us now to find out more about how our AIR XD and XD ONE real-time dust monitoring products – accurate, simple to use, easy to maintain, real-time particulate detection technology can protect your workers in your hazardous environments.

It’ll come as no great surprise: the more hassle something is, the less people want to do it. A simple fact, from technology, to sport, to entertainment, to business, the ‘more trouble than it’s worth’ factor relates to every aspect of life. There’s even a model that represents it. Fred Davis’ 1986 Technology Acceptance Model (TAM) designed to measure the adoption of new technology based on customer attitudes.

The time, the trouble and the expense of ‘high maintenance’ dust monitoring equipment goes a long way to explaining why it has never really been adopted to the scale that workers truly deserve.

Traditional dust monitoring equipment:

– Takes too much time to deploy

– Needs continual fiddly maintenance

– Costs too much money

– Is often too big, too heavy and too fragile

– Is too much hassle

Which is why we’ve worked so hard to develop, manufacture and distribute the Trolex XD ONE Portable Dust Monitor.

The new, easy-to-use, low maintenance, reliable and accurate personal dust monitor; more like a PPE product than a traditional high-maintenance dust detector or analyser.

Let’s take a look at the Trolex XD ONE Portable Dust Monitor, in particular its ease of use, deployment and maintenance, against the leading products already on the market.

Let’s see how they compare – or more realistically – how they don’t. Because, as you’ll see for yourself, the advantages of the XD ONE are so many and so significant that any genuine comparisons are few and far between.

How easy is the unit to wear, use, and get working?

Trolex XD ONE Portable Dust Monitor: Pick it up. Switch it on. Off you go…and go…and go.

Compared to:

TSI SidePak AM520/520i: Larger and 30% heavier than the XD ONE. Requires different impactors for different particulate sizes that need to be recalibrated as they’re swapped out. Fiddly tube clipping required.

SKC HAZ-DUST IV: Three-times heavier than the XD ONE at 1.4 kg and much larger. Base unit + tube + sampling head clipped near breathing zone with separate filter unit.

CASELLA APEX 2: Requires a clean environment and tweezers to handle the filter. Flow meter and calibration adapter kit not included and needs to be purchased separately.

Nanozen DustCount 9000: Base pump unit with impactors, tube to head unit with filter in cassette and sensor. The usual set-up with the usual problems. Don’t forget to remove the red cap before switching on or you’ll damage the unit!

TM DATA II: Much bigger and 20% heavier.

What kind of burden does the typical maintenance cycle put on the user?

Trolex XD ONE Portable Dust Monitor:

– Five seconds for automatic or on-demand self-testing

– 60 seconds of compliance every six months

– No return-to-base, complex set-up or calibration

– That really is it. PPE for the real world

Compared to:

TSI SidePak AM520/520i:

– Recommended annual return-to-base

– Impactor maintenance – eight-step process

– “Impactor should be cleaned prior to each use.” – TSI website

– Cyclone maintenance – complete disassembly and reassembly

– Separate filter unit required to perform daily calibration check

– Multiple monitors required to bump test in the field. It is very difficult to generate a known aerosol concentration for a ‘bump test’ in the field without very sophisticated equipment. With use of multiple SidePak Monitors running them side by side…if all instruments are within 20% of each other, they are all functioning properly’ TSI website

SKC HAZ-DUST IV:

– 81-page manual

– “Sensor optics to be checked every 48 hours when used in a 2-3 mg/m³ TWA environment and on a weekly or monthly basis in less contaminated environments” – eight-step cleaning process using a bespoke kit

– Flow rate must be checked every time a new gravimetric filter Is used – six-to-eight-step procedure

– Calibration every month as a minimum/when dropped – minimum 11-step procedure

– Annual third-party calibration required

– 19 accessories

CASELLA APEX 2:

– Annual return to base/or after 2,500 hours, whichever is sooner

– Loaded filter or battery voltage reductions affect air flow speed requiring variable flow to be monitored at all times. In-built pressure and temperature compensation, pulsation control, high back pressure and long battery life presented as great ‘features’ of their product when in fact they’re all only necessary because of the antiquated filter-based methodology used

– Inlet filter to be replaced every three months (more often in challenging environments) four-stage process

– Different filters are required for different applications and this needs to be worked out

Nanozen DustCount 9000:

– Recommended annual return to base

– Impactor has to be oiled and cleaned – fiddly with small pipettes of special oil and a three-minute wait before re-assembling and cleaning with a special alcohol substance

– New filters need to be inserted into the filter cartridge. A screwdriver, clean area and tweezers required

– Pump needs to be calibrated. Separate filter unit required to do this

TM DATA II:

– Special calibration kit required

– Measuring chamber cleaned with oil-free pressurised air or with soft dry brush

– Light trap covers can be screwed out so that dust particles can be blown out of the light trap

– Lenses in front of the diodes can be cleaned with Q-tip wetted in alcohol

– Internal calibration and zero-point adjustments should be carried out on regular intervals

– Maintenance and repair only by qualified personnel

The Trolex XD ONE Portable Dust Monitor – a device that’s so easy to use and maintain, so useful, that it’s more hassle to NOT use it.

And when you start to tot up the cost benefits of the XD ONE over its competition, it’s hard to know where to start.

– The time saved in setup

– The hours of maintenance saved

– The savings in extra disposable kit

– Improved site performance

– Lower worker absenteeism

– Recruitment cost savings

– Reduced legal and litigation costs

Perhaps the greatest benefit though is one that can’t be measured in monetary terms – the opportunity to prevent your workers from suffering avoidable, life changing disease, and premature death. Priceless.

There’s a well known sales mantra that goes: “People don’t buy the best – they buy products they can understand the fastest.”

The same principle applies to technology adoption.

People don’t buy the best – they buy products that are easiest to adopt.

The great thing here is that not only are Trolex products the easiest to adopt, they’re more accurate, far simpler to maintain and significantly cheaper to use than anything else in the market. The best.

So, when the question is:

‘How do we best encourage people to use dust monitoring equipment and to keep using it because it’s easy to deploy and easy to maintain?’

The answer is as simple as it’s effective.

The Trolex XD ONE Portable Dust Monitor.

If you’d like to find out how real-time dust monitoring can help improve your safety processes, get in touch today.

Did you hear about the plane crash that killed everyone on board? Your answer likely depends on where you live.

According to researchers at the University of Oxford: ‘English Wikipedia readers were much more likely to read about North American and European crashes, and Spanish Wikipedia readers were more likely to read about Latin American crashes.

Page views on English and Spanish Wikipedia for North American and Latin American aircraft crashes, respectively, were each about 50 times greater than for African crashes.’

These events are tragic, to be sure, but the deaths from these situations are more generally heard about than others, such as from dust inhalation – despite technology and processes available to help prevent them.

It also depends on when the crash happened, with Royal Society Open Science discovering that irrespective of the crash location and body count, ‘on both English and Spanish Wikipedia, page views dropped in half between three to 10 days after the event’. The decay of novelty as we lose interest in things when they stop being new.

And then there’s how much capacity you have left to care, the concept scholars refer to as the ‘finite pool of worry’.

‘Because people have a limited capacity for how many issues they can worry about at once, as worry increases about one type of risk, concern about other risks may lessen.’ says The Centre for Research on Environmental Decisions.

Proximity. Timing. The competition with other concerns for a limited capacity to impact emotions. It’s a complicated old business. Disaster, its impact, its legacy and even the ways we look at – or away – from it. That’s only talking about sudden disastrous events; the plane crash, typhoon, earthquake, and other similar events.

What about the disaster that inexorably unfolds? The slow-motion cumulative disaster. Disaster that – over time – takes far more lives than the one off tragedies? Or even a succession of one-off tragedies?

What about:

As we’ve seen, it’s human nature to focus on more recent, local, high-profile events. Discreet, distinct, storylines.

However, don’t the disasters we overlook – the slower moving, less attention-grabbing tragedies that play out day after day – deserve our attention too?

The problem of particulate and dust inhalation is widely ignored, so too is the priority in finding viable solutions.

This is why we do what we do at Trolex, and why we’ve set ourselves the challenge of reducing the risk and impact dust inhalation can have on workers around the world who are rarely spoken about.

This is done through the development of technology like the AIR XD Dust Monitor, XD ONE Portable Dust Monitor, XD1+ Personal Dust Monitor and AIR XS Silica Monitor alongside supporting software, to deliver data in realtime and make sure every worker knows the state of air around them.

We haven’t stopped there, however. Our engineers are constantly asking “what can we do so that, in 10 years time, every worker in the world exposed to dangerous particulates is wearing personal dust monitoring?”

This is easier said than done, of course, but it’s a challenge we’re committed to undertaking and beating. As well as setting ourselves the task of overcoming the engineering challenge, we’re having to face those natural ‘hidden in plain sight’ biases discussed above.

We’ve privately funded each project every step of the way – from research and development, to manufacturing and distribution. Every penny.

Not that we mind. In fact, we’re proud to have independently conceived and created our range of real-time dust monitoring products: innovative dust monitoring technology that’s now the envy of the industry.

These products are perfectly capable of helping us meet our 10-year challenge, and in the process save many thousands of lives.

Set against the backdrop of Covid-19 and the billions and billions of pounds spent to combat it, the macabre irony hasn’t been lost on us, that worldwide more people have died inhaling dangerous particulates in the last five years than they have from Covid 19.

Unnecessary deaths that for only a couple of million pounds backing, our technology could still go faster and further in preventing.

Maybe we should call for a lockdown?

We work with businesses around the world to improve the safety of hazardous work environments and give workers a better chance at reducing the risks of dust inhalation. The long term effects can be severe and, while it might not be as obvious or attention grabbing as other tragedies, we’re committed to doing what we can to help those at risk.

If you’d like to know more about our dust monitoring systems and how they can help your worksite, get in touch with our team of experts today.

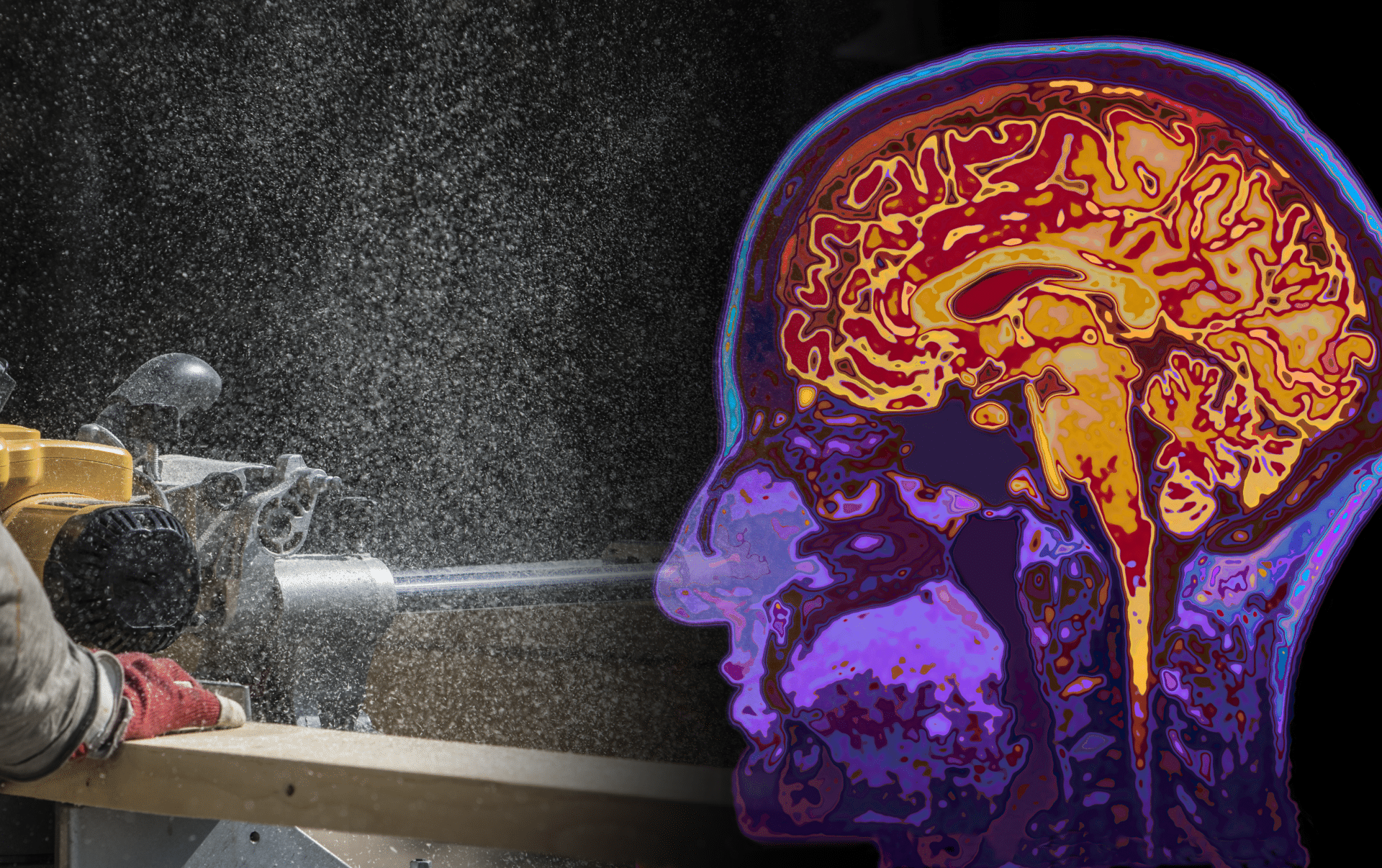

As if the known dangers of exposure to harmful respirable dusts weren’t bad enough, new research is showing that long-term exposure to ambient air pollution is associated with a far wider range of diseases and highlights the importance of particulate monitoring.

Not only are 1.4 million people in the UK reporting ‘lung or breathing problems that were caused or made worse by work,’ and 12,000 people dying every year due to occupational lung diseases, evidence is mounting to show that airborne pollution also causes dementia, strokes and skin cancer.

The study, conducted in the USA and first published in the journal Stroke is titled “Long-Term Exposure to Fine Particulate Matter, Residential Proximity to Major Roads and Measures of Brain Structure“.

Examining the brains of more than 900 people over 60 years old, it revealed that long-term exposure to fine dust causes both brain atrophy (brain shrinkage) and leads to an increased risk of stroke and other disease.

Not only is this news alarming for those who live near busy roads, it also draws attention to the added dangers faced by those working in conditions, and with materials, they may have previously thought safe.

For example, welders, who, despite now using supposedly less dangerous materials and working in spaces where local exhaust ventilation (LEV) is employed, seem to be vulnerable to a far wider range of illnesses than previously thought.

As the report highlighted, even limited exposure of fine dust particles can lead to the heightened risk of cerebrovascular disease and cognitive impairment.

Benjamin Howell on the Fabricator.com says, ‘at the nanolevel, invisible to the human eye, the concentration of particulate matter can pose a great risk to welders. Studies show that welding fume particulates are mostly smaller than 0.1 micrometer, which makes nearly all welding fume particles respirable. They can penetrate deep into the alveolate region of the lungs during inhalation and remain firmly fixed there.’

It’s not all bad news though.

By revealing far greater and far wider reaching dangers than previously acknowledged, the new research means the important issue of how best to protect people from damaging dusts is getting the attention it deserves.

The sheer weight of evidence amassing from the likes of The Journal of Cleaner Production, The British Medical Journal, and Harvard is forcing the hand of governments, regulatory bodies and employers. The necessary steps to protect not just their workers, but every one of us exposed to dangerous airborne pollutants, are being considered and taken. This includes controls, sensors and dust detectors, among other things.

What if a threat could be detected before it even became a threat? What if you could be alerted to the presence of even the smallest of damaging airborne dusts before they had the chance to damage health?

Leading H&S expert John Cairns says:

“The best thing is to detect the hazard before you’re exposed to the hazard. Before you’re exposed to the hazard or a high concentration. You can get the hell out of there, or with the way this new technology works you can set off ventilation systems to clear the area.

The whole ethos behind the Health and Safety Executive (HSE) is to reduce the risk to as low as is reasonably practicable. I think the XD ONE Portable Dust Monitor is adding to that – it’s enhancing the safety system.”

Real-time dust monitoring is an effective way at reducing the risk to workers in hazardous working environments. When combined with RPE, PPE and other equipment, the threats from dust and particle inhalation are reduced drastically. This has a big impact on worker health, morale and productivity.

Send us a message today to find out more about our work to help organisations like yours protect your people from the threat of damaging dust particles with sensors, dust detectors and systems tailored to your work environment.

A sign of things to come.

Despite the protests of Johnson and Johnson, who played the indignation card at a “fundamentally flawed trial, grounded in a faulty presentation of the facts.”

The verdict is “[at] odds with decades of independent scientific evaluations confirming Johnson’s Baby Powder is safe, does not contain asbestos and does not cause cancer,” they quibble.

$2.12 billion in damages tells another story.

That’s what a Missouri court ordered Johnson and Johnson pay to women suffering ovarian cancer caused by asbestos in its baby powder and other talc products. Litigation that looks like just the beginning.

Not just for Johnson and Johnson, who now face‘21,800 lawsuits claiming that its talc products cause cancer because of contamination from asbestos, a known carcinogen,’ but also for the many employers the world over who fail to properly protect their workers from preventable disease.

Sarah Jardine, HSE’s chief inspector of construction says: “Around 100 times as many workers die from diseases caused or made worse by their work than are actually killed in construction accidents.”

In the UK alone, 14,000 people a year die prematurely from largely preventable disease caused by the inhalation of respirable dust in the workplace.

Preventable because there’s no excuse for remaining ignorant of the potentially fatal consequences of exposure to dangerous microscopic airborne dust particles.

While lack of awareness has certainly been a problem in the past, now, with plenty of readily available research, public health messaging and examples of high-profile litigation, there’s simply no reason for companies to ignore their responsibilities,

Especially following new advances in dust measurement technology.

So not only is ignorance (still) an illegitimate excuse, with new real-time dust monitoring technology that provides you and your workers with real time and highly accurate dust readings in any working environment, so, too, is blaming a lack of suitable technology.

Put simply, if you’re serious about running a business you need to be serious about protecting people from the dangers of dust inhalation that surround them. Serious about both understanding those dangers and then putting the measures in place to mitigate them.

And as if the moral obligation wasn’t enough, the commercial implications are enormous, too; as Johnson and Johnson are discovering.

There’s more to worry about than the obvious bottom line legal costs and compensation. You need to consider the reputation costs in the form of lost business opportunities and even share price, insurance premium hikes, loss of production or reduced output, sickness cover and pay, and the lack of future legal and financial protections. All the many, undesirable and inevitable consequences of being exposed as negligent. The last thing any business needs or wants.

Are you still unclear about the extensive danger of dust? Or do you already realise the danger, want to do something about it but are unsure how real-time dust monitoring technology can help you?

Either way feel free to get in touch. We’ll tell you the many ways that we help businesses across all sorts of sectors, all over the world. Everything you need to know about protecting your workers from the threat of disease, and your business from the threat of litigation. And all its damaging implications.