A manufacturer of prestigious natural stone, Burlington Stone have quarried for over 200 years across the English Lake District, extracting and crafting a diverse range of signature British natural slate and stone products.

Individuals across their workforce are often exposed to hazardous substances, most notably airborne dust, including silica dust. Burlington Stone trialed two XD1+ devices on their site for a month to see how real-time, personal dust monitoring would improve their safety processes.

After the trial, we spoke to Health and Safety Manager, Peter Walker, about the success of the trial and some of the major benefits which Burlington Stone’s workforce found deploying XD1+ Personal Dust Monitor units in their day-to-day processes.

Our AIR XS Silica Monitor, an innovative real-time respirable silica (RCS) monitoring device, has been deployed at a major railway operations project to monitor the levels of RCS which workers may be exposed to.

The Central Rail Systems Alliance (CRSA), an alliance between Network Rail, Balfour Beatty, AtkinsRéalis and TSO have been using an AIR XS unit to monitor the levels of RCS released when damaged rail tracks are replaced; when rail track is damaged or needs replacing, the ballast surrounding the track is disturbed and can release RCS. The AIR XS unit was supplied by our UK partners Sunbelt UK & Ireland.

The challenge faced by CRSA was to measure the level of RCS and accompanying dust being released into the atmosphere during the unearthing process of 425m rail and ascertain the level of risk associated for those working in the immediate and surrounding environments. The AIR XS unit was manoeuvred around the site in-line with project progress, so that working scenarios can be accurately represented in the data set.

Upon conclusion of the project, Madeline Dunn, the Health and Safety Advisor for CRSA praised the monitoring and recording capabilities of the AIR XS, saying “We have completed trials prior, however this is the only unit where it is measuring silica and not just general dust levels. We gained the knowledge that the exposure levels were actually higher than we anticipated with even low-level ballast disturbance.”

Thanks to the team at Sunbelt Rentals UK & Ireland for the in-depth case study which you can read in full here.

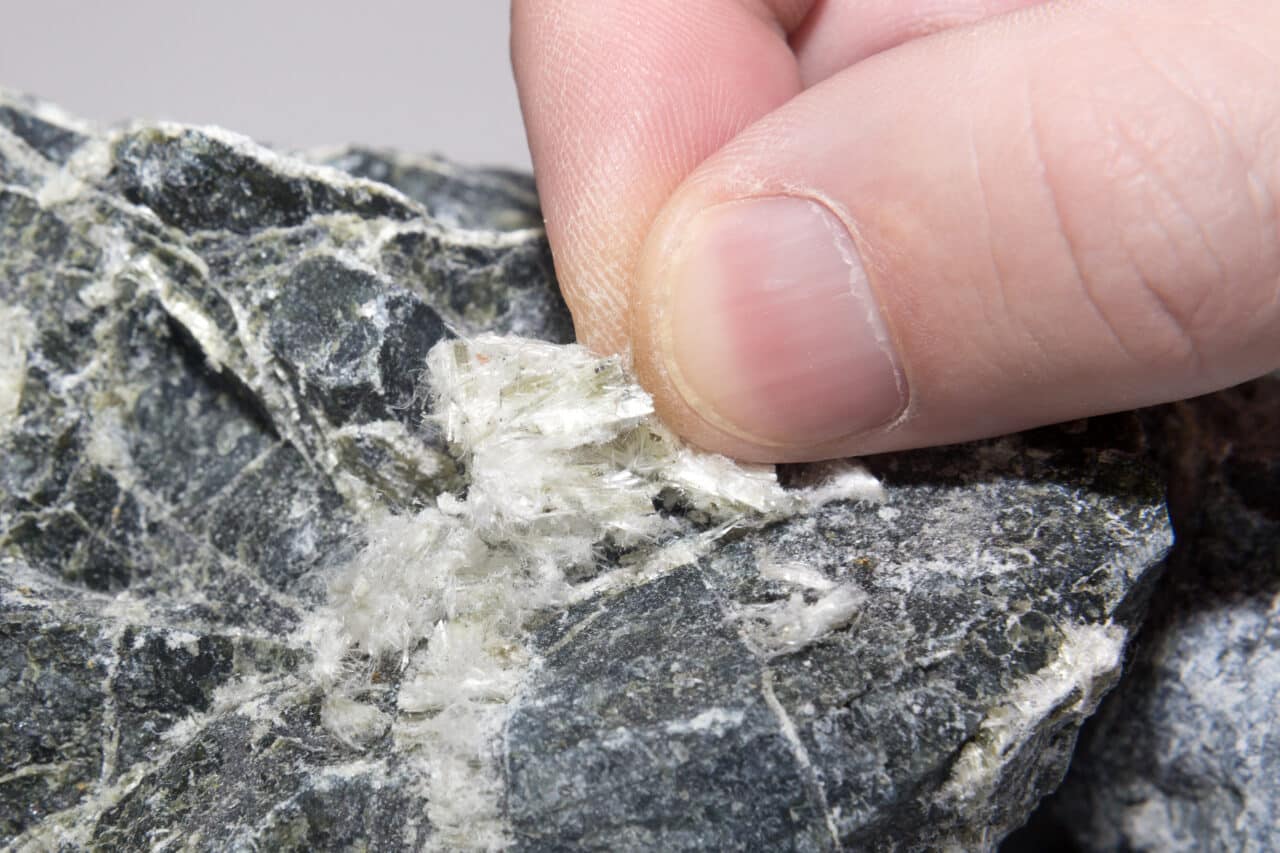

Silica dust is the new asbestos.

But what if it’s not? What if there’s really nothing new about silica dust in relation to asbestos?

The link between the two is even closer than you may think…

Most people know asbestos as the dangerous insulator used in construction, responsible for over 5,000 related disease-deaths per year, typically lung cancer and asbestosis.

However, in its natural form, asbestos is a naturally occurring fibrous silicate mineral.

Put simply, silicate minerals make up asbestos fibres.

Asbestos is actually just one of the many different forms of silicate materials, in the same way that silica dust is.

The similarities between silica dust and asbestos are much closer than people are aware of.

There is a different attitude towards asbestos compared to silica dust.

The dangers of exposure to asbestos are well documented.

Exposure to asbestos can cause serious lung conditions, including asbestosis and mesothelioma. It is the number 1 cause of recorded work-related deaths in the world.

Most people in the UK are aware of its dangers, particularly as asbestos was banned in 1999 for construction work in the UK.

Yet despite all of this, very few people are aware of how dangerous exposure to silica dust is, despite the fact that asbestos fibres are made up of silicate materials, in the same way silica is.

There are many more dangers relating to silica dust than people may be aware of.

Imagine you are working on refurbishing your bathroom and from the grinding of the ceramic sink and a load of dust becomes airborne.

If you were told that this airborne dust which you were inevitably inhaling was asbestos, you’d probably run a mile, right?

And who could blame you? A dust which is responsible for approximately 90,000 asbestos-related diseases per year. You’d want to get as far away from it as possible.

Well, it’s likely that that dust in your bathroom would in fact be silica dust.

A dust which is made up of silicate materials in the same way asbestos fibres are. A respirable dust which is just as lethal, if not more lethal, in comparison to asbestos dust.

But because it isn’t known to people as being the same as asbestos, the dangers seem to be less of a concern to people.

It’s time to get real and become aware of just how dangerous silica dust is.

It is reported that, in crystalline form, respirable crystalline silica (RCS) is responsible for the death of 600 people per year in Great Britain with 450 of those to workers in construction industry. What’s more, an estimated 50,000 workers are exposed to silica dust globally.

The importance of the dangers of silica dust must be realised, especially with what is known about how dangerous asbestos is.

Asbestos is just as lethal as silica dust. The dangers are the same, yet we cannot afford for the results of exposure to silica dust to be the same as what occurred with asbestos.

Silica could be as lethal as asbestos, if not more so, with equally serious consequences.

Being aware of the issue is the start, action must be taken to protect workers from this dangerous dust.

We cannot afford to let history repeat itself.

New studies from charity ‘Asthma and Lung UK’ (ALUK) found that lung disease deaths in the UK are the highest in Western Europe.

The staggering statistics have prompted an expanded approach towards research and development of lung diseases from ALUK.

ALUK’s studies show that cases of lung disease related deaths in the UK have been on the rise for the past 20 years.

It is reported that 500,000 people in the UK died from deaths relating to lung diseases over a seven-year period.

In 2018 alone, 84,721 respiratory deaths were recorded in the UK.

The charity has described the state of lung health in the UK as ‘shameful’, stating the need for improved research and development solutions to the problem.

After its relaunch in February, ALUK established a new five-year strategy upon the results of the study.

Lung diseases are currently the third most common cause of death in the UK and it’s currently costing the NHS £9 billion every year.

Despite this, lung-related health care is receiving less than 2% of public funding.

It is evident that the seriousness of lung problems in relation to other diseases is not taken as seriously, despite what we are seeing from the data.

A predominant factor in the poor state of the nation’s lung health is that people believe lung conditions aren’t life-threatening. This is a major misconception.

Through spreading awareness of how ‘shameful’ lung health is in the UK, this misconception can be dispelled.

ALUK aim to reduce lung disease deaths by 20% by 2027. When making everyone aware of these gruesome statistics, this can become a possibility.

The end goal is to provide support for everyone effected by all forms of lung disease.

ALUK’s solution to achieving this goal is through research and innovation.

Their aim is to expand their research and innovation programme so that £5 million is being invested into relevant research each year.

With the aim to “develop at least three new self-management tools” for 2 million people suffering with lung diseases, ALUK want to make training programmes and essential advice easily accessible to those who need it.

“By 2027, we will give 80% of people with lung conditions the opportunity to access our network of Breathe Easy support groups” states the ALUK Strategy to 2027.

With this, the strain on public healthcare is minimised and individuals are able to monitor their personal health through digitalised platforms and shared networks.

The statistics right now make for harrowing reading and harsh truths.

However, for ALUK, research and innovation is the solution for the future. By identifying the problem and acknowledging its severity and scale, goals can be achieved.

Through effective research and innovation lung disease deaths can become a thing of the past, not just in the UK, but worldwide.

Trolex are excited to be partnered with Active Environmental Solutions (AES), working together to protect workers from the dangerous and often irreversible consequences of occupational lung diseases caused by dust inhalation.

With AES’s specialist knowledge of occupational health and safety in Australian industries and Trolex’s leading safety technology, the opportunity of delivering solutions to prevent the dangers of dust inhalation for Australian workers, is not just a possibility, but now a reality.

AES want to spread awareness of the dangers of occupational lung diseases caused by dust inhalation. And in the case of dust monitoring, spreading awareness that new real-time dust monitoring technology to help prevent lethal occupational respiratory diseases now exists.

The opportunity to partner with Trolex was welcomed by AES, as it means that they can merge their expertise in occupational health using Trolex’s leading safety technology.

This creates the best solutions to their respective industries.

This simple message appealed to AES, and to Aleks Todorovic MSc, (OHP), Managing Director of AES’s team of Australian Occupational Safety experts at AES, as it aligned perfectly with the workers they seek to protect:

“Many businesses intuitively know the benefit of a broad threat detection – they just don’t know they know it, or perhaps how they go about implementing such devices – it’s our job to awaken that knowledge and show them there are new and effective dust detection technologies such as the Trolex AIR XD Dust Monitor, the XD ONE Personal Dust Monitor and most recently, the AIR XS Silica Monitor.

There are no arm twisting, or heavy sales techniques involved. Just a clear and simple presentation of responding to the facts.

Which is why Trolex and AES are working hard to provide further education to Australia’s mining, tunnelling, quarrying and construction industries, where workers are exposed to dangerous forms of respirable dusts.

This common goal of providing and expert knowledge and specialist equipment to these industries is the drive needed to inevitably reduce instances of occupational lung diseases to save lives.

Now, this collaboration will help to do exactly that.

The approach taken by businesses within these industries must now change. With new legislation on exposure to harmful dust in Australia, new dust monitoring methods are needing to be implemented.

Aleks said “As an occupational hygiene-minded business we know only too well the devastating effects inhaling respirable dusts can have on people’s long-term health.”

“That’s why we’re invested in the success and distribution of new and effective real-time dust monitoring technologies such as the Trolex AIR XD Dust Monitor, the XD ONE Portable Dust Monitor and the AIR XS Silica Monitor. These are lifesaving technologies that need to be included in their safety thinking” stated Aleks further.

By using Trolex’s advanced dust monitoring technologies, small changes can have a huge impact.

As the war on silica dust grows ever stronger by the day, more needs to be done.

With the reduction in exposure limits coming into effect across Australia, particularly hard on respirable crystalline silica (RCS), real-time monitoring for silica dust is a necessity, retaining live data and providing an instant alarm the legislated threshold is breached.

Whilst the ability to retrospectively assess levels of silica dust in facilities is available to industries where deadly silica dust is prevalent, the ability to monitor for silica dust in real time is not.

Trolex’s all new real-time silica monitor, the AIR XS, allows for accurate and reliable results demonstrating compliance with legislation. Aleks commented on this world-first technology:

“We are really excited to be a part of this project to be able to detect silica in real time. This will be the world’s first monitor to have this capability and we’re proud to be distributing it throughout Australia. The project was produced with the support of the Centre for Work Health and Safety in NSW proving just how important and potentially life-saving the new technology will be.”

And with the talk of real-time, wearable silica monitoring devices a possibility in the future, of course it makes perfect sense for all industries to be increasingly focused on detection possibilities.

Together, Trolex and AES are providing real solutions for real problems in Australia.

If you’d like to speak to one of our experts about integrating real-time dust monitoring technology into your working environment, then you can use the contact form below to get in touch with one of our experts today.

The IOSH Construction Group Committee Construction Dust Survey makes for sobering reading. Firstly, it highlights the fact that much more needs to be done to increase awareness of the dangers of dust from an employees perspective:

“Dust causes a lower level of concern among employees than the more immediately noticeable dangers of construction, such as falls…they do not perceive it as a significant immediate risk to their wellbeing unlike falls from height, equipment etc.”

It also highlights a lack of awareness from the industry as a whole. Of 618 health and safety professional respondents, ‘44.6 percent thought that the industry gave little or no priority to the issue, and a similar proportion (42.4 percent) felt that it received the same priority as other health issues.’

And even when awareness exists, the report found that compliance is weak.

‘54.0 percent of respondents indicated that workers sometimes fail to follow prescribed methods of work. Over a third of respondents (36.2 percent) indicated that this happened most or all of the time.’

So what’s going on? Why, even when employers and their onsite teams are in possession of the facts, do they too often choose to ignore the dangers posed by dust?

Dangers that lead to 10 deaths a week from lung cancer caused by silica dust, let alone the other illness and premature death from other cancers, silicosis, asthma and chronic obstructive pulmonary disorder (COPD).

You’ll be familiar with the concept of cognitive dissonance, ‘the state of discomfort felt when two or more modes of thought contradict each other’.

Like knowing smoking is bad for you, but continuing to smoke.

Like, “we know dust is dangerous but there’s no convenient, low-cost alternative to handling the risk. So we’ll stick with what we’ve always done.”

Barriers to change

There’s a lot to learn in the Construction Dust Survey.

More than anything, it’s highlighted that despite being increasingly aware of the dangers, people aren’t taking action.

Somehow, industry has convinced itself that the culture and adoption of, the management of, and the cost, complication and general hassle of creating a safe working environment is more trouble than just leaving things be.

Here are just some of the barriers to change noted in the survey:

Culture: The culture of the industry, and its ‘traditional’ view of dust as an expected or normal part of construction work, can be a significant barrier.

Use: Workers often view the controls as cumbersome, impractical, affected by poor maintenance or giving rise to other risks. This deters use.

Employees: Implementing controls effectively depends on good management and supervision. Operators generally choose not to use controls.

Management arrangements: In general, the industry does not seem to manage dust control issues adequately. Comments refer to a link between the management priority given to this issue and the corresponding conditions found on-site.

Cost: Dust control is often viewed as labour-intensive, expensive, time-consuming and a nuisance that slows work.

‘The industry creates this risk. It now needs to acknowledge it, own it and deal with it.’

It somehow seems that as awareness increases, industry seems to think a cultural shift towards safer working environments will run its own natural course over time.

“It is like wearing a hi-vis 15 years ago or hard hats. It took years for the culture to change.” says a contributor to the report.

Fortunately, we’ve taken a far more proactive approach.

What if we could fast track that safer working environment?

What if that cognitive dissonance could be eased instantly and increased awareness could be achieved overnight? And what if you only ever had to use dust control methods when you actually needed them?

It’s hard to not be aware of something when an alarm is screaming in your ears and bright lights are flashing.

Well, here’s the thing.

A low-cost, simple-to-use, personal alarm would help solve the problem overnight.

All those adoption and implementation objections, all the excuses and all those barriers to change would evaporate. Instantly.

And here’s another thing.

That low-cost, simple-to-use, personal alarm exists.

It’s new and it’s here.

The XD ONE Portable Dust Monitor.

Get in touch today and we’ll tell you everything you need to know about how real-time dust and silica monitoring technology can protect your workers from the threat of preventable disease.