With an estimated 1 million people dying globally from the inhalation of dust in occupational environments every year, now is the time to protect your workers. Real-time dust and silica monitoring provides instant alarms and alerts for all workers at risk of dangerous dusk regardless of their application, processes or industry.

We’re continuously innovating real-time dust monitoring technology to give you access to the information to effect change and keep your workers safe from hazardous respirable dusts. With a range of dust and silica monitoring options, we’re here to help you protect your workers.

Whether that’s heavy-duty area monitoring for high dust loading environments, personal dust monitoring for individual monitoring needs, or silica monitoring for working environments with high respirable crystalline silica (RCS) content, such as stonemasonry, tunnelling or quarrying.

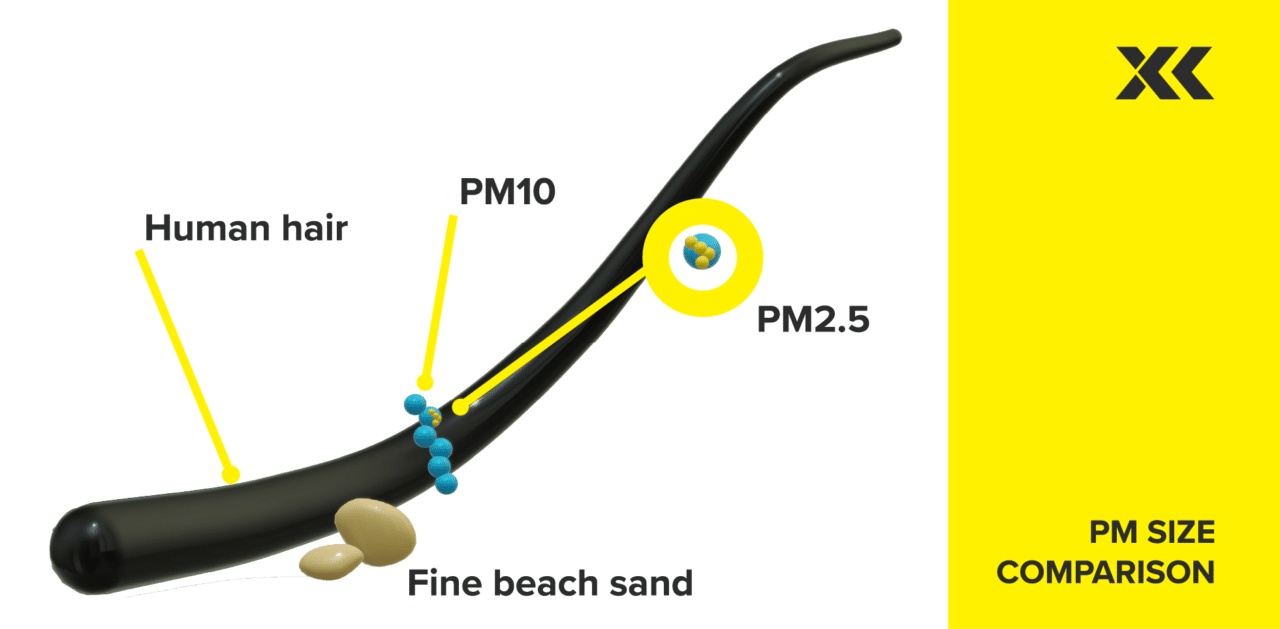

‘PM’ or particulate matter, also known as particle pollution is the term for a mixture of solid particles and liquid droplets found in the air.

It’s estimated that air pollution is linked to 43,000 deaths per year in the UK. Worldwide, at least 7 million people die each year from exposure to air pollution, with 91% of the worldwide population living in locations where the air quality exceeded the World Health Organisations (WHO) air pollution guidelines.

These guidelines state that that annual average concentrations of PM2.5 should not exceed 5 µg/m3 and PM10 should not exceed 15 µg/m3 (both for 24-hour periods). According to the WHO, ‘fine particulate matter at PM2.5 can penetrate through the lungs and further enter the body through the blood stream, affecting all major organs’. Exposure to dust at PM2.5 can cause serious disease to the respiratory system, such as lung cancer and COPD, and also can effect cardiovascular diseases, such as a stroke.

The image below demonstrates PM2.5 and PM10 size in comparison to a single human hair and a grain of sand.

The Department for Environment Food & Rural Affairs (DEFRA), the UK government ministerial department for environment protection, have also highlighted the severity of exposure to air pollution. This growing concern for the UK government estimated in 2010 that the cost of health impacts of air pollution was likely to exceed estimates of £8bn to £20bn.

Although between 2005 and 2022, the UK’s PM2.5 emissions decreased by 41%, emission levels have been relatively steady with small annual fluctuations in the last decade. Industrial combustion is a major source of PM emissions, as well as emissions from industrial production also playing a major part, which can be linked to heavy-dust industry where hazardous particulates can become airborne. Despite some reductions in PM emissions, the threat still very much remains.

A solution to this is real-time dust monitoring. Real-time particulate monitoring allows people in heavy dust loading environments, including industrial applications, to not only understand, but alert them instantaneously when they are exposed to dangerous levels of air pollution. For example, our AIR XD Dust Monitor can alert people in real-time when legislative levels of µg/m3 are breached, over a time-weighted average (TWA) 8-hour period, for both PM2.5 and PM10.

This technology not only offers a simple solution to individuals at high risk of exposure to air pollution by providing instant alerts, but also can help to prevent exposure in the future, as at-risk individuals can learn exactly when and where exposure to air pollution is highest and will likely occur. Thanks to real-time monitoring, both in the UK and Worldwide, we can reduce exposure to air pollution.

The AIR XS Silica Monitor leverages cutting-edge Optical Refraction Technology (ORT) to enhance workplace safety by providing real-time monitoring of respirable crystalline silica (RCS). Unlike traditional particle monitors, AIR XS distinguishes and measures RCS content, enabling immediate detection and response to harmful silica dust levels. This technology is crucial in combating occupational lung diseases such as silicosis, which affects millions of workers globally.

Current monitoring methods, like gravimetric sampling, are time-consuming and often deliver results too late to prevent exposure. In contrast, real-time silica monitoring offers immediate data, significantly reducing the risk of occupational silicosis by enabling prompt action to mitigate hazardous conditions. The importance of such real-time data is highlighted by cases like Joanna McNeill’s, who developed silicosis at the age of just 36. Her story, like many others underscores the necessity for continuous monitoring to protect workers from the threat of silicosis, regardless of their occupational environment.

Our real-time RCS monitor, AIR XS provides a real-time solution to this threat. Workers are not only alarmed and alerted when silica levels exceed legislative limits but can work to best practices by implementing AIR XS with the Hierarchy of Controls, supporting proactive measures to eliminate or minimise exposure to RCS. This move to real-time monitoring as a solution to the threat of silicosis has also been noticed by governing bodies, like the All-Party Parliamentary Group on Respiratory Health.

To learn more about how this real-time solution not only enhances worker safety but also streamlines business operations, click the link below to read the case study in full.

With over 45 years of experience in the field of tunnelling, our partners, Timeco, are experts when it comes to tunnel boring machine (TBM), piling and foundation works, and other important activities involved in tunnelling. And when it comes to environmental monitoring for harsh tunnelling conditions, their partnership with Trolex has provided solutions to the entire tunnelling industry.

“We are satisfied with the 20+ years of cooperation with Trolex, as our official partner, because of the mutual trust in the innovative organisation and the reliability, user friendly

and durability of its products and solutions.” said Timeco, about the collaboration with Trolex to provide solutions to hazardous conditions in the tunnelling industry.

Trolex’s product range, provided to the tunnelling market in Europe by Timeco, includes a full range of dust monitoring technology, including AIR XD Dust Monitor and AIR XS Silica Monitor, as well as gas detection equipment, such as TX9165 Sentro 8 and TX6351-2 Sentro 1, detecting for a full range of hazardous gases.

The connected XD1+ Personal Dust Monitor and Reactec cloud-based analytics platform has arrived. The Reactec Analytics platform brings exposure data from the XD1+ to life by delivering real-time updates from individual workers and tracking respirable data to determine where the highest concentration of harmful dust exists in your workplace.

With no filters, pumps, tubes, or replaceable parts, the XD1+ Personal Dust Monitor is one of the most compact, lightweight, and easy-to-use real-time personal dust monitors on the market. For such an accurate and reliable unit, it is also essential to be able to access and easily understand the data which the XD1+ is picking up, minute by minute.

Reactec’s cloud-based analytics platform brings XD1+ exposure data to life by delivering real-time updates from individual workers to remote supervisors, whilst tracking respirable data, to determine where the highest concentration of dust exists in your workplace.

With the support of Reactec’s Ecosystem, the XD1+ is transformed into a connected, personalised dust monitoring device that shares invaluable data insight to key stakeholders and figureheads. The XD1+ is integrated into the Reactec Ecosystem using the Reactec RASOR device as an IoT Gateway to Reactec’s powerful A=nalytics software.

By simply connecting your XD1+ unit to the Reactec Analytics platform you are able to:

Protecting the health and safety of the people who work for you is the ethical thing to do. It also makes good business sense as your people are your greatest asset.

But even if you aren’t driven by a moral or financial imperative, governments around the world are toughening up on the legislation that protects workers, so it’s not something any business can afford to ignore.

While some threats are obvious, others are invisible and incredibly hard to accurately detect, such as the deadly silica dust that are the by-product of many industries and manufacturing processes.

Silica dust is linked with severe health problems. It has been dubbed the ‘new asbestos’ and has already been the subject of litigation. Yet it’s something that has historically been impossible to monitor in real time.

Our Construction Industry Health and Safety Survey Winter 2021 shows that employers are concerned about safety, with nine out of 10 respondents recognising that worker safety is important or very important.

But it also revealed that on the ground it can be hard to meet the health and safety challenge, particularly when it comes to dust monitoring, which for a fifth of respondents accounted for half of their safety budget.

This in-depth report looks at how real-time, wearable dust monitoring technology can help to solve the issues from the findings of the Construction Industry Health and Safety Survey Winter 2021.

The findings ultimately mean that it’s clear we need a new approach to dust monitoring. One that looks to the future and is inspired by the intelligent tech revolutionising every other aspect of our lives.

It’s time to act now to tackle danger of hazardous dusts, like silica dust, by investing in smarter solutions to protect the air we breathe, with real-time dust monitoring.

Based in Salford, M&E contractor Thermatic Homes has more than 70 electricians out in the field rewiring properties for social housing providers including The Wates Group, Unitas, Brunswick Regeneration and Bolton at Home. As an ex-electrician himself, Thermatic MD Karl Wallace is aware of the dust challenges their work creates.

“There are a lot of issues created by dust,” he says. “Chasing through to the brickwork and masonry is extremely intrusive and there’s a huge amount of dust created. We’re conscious that it’s potentially a dangerous environment if not controlled properly.”

Which is why Thermatic electricians always use dust extraction on their CHASE machines. Why they always wear dust masks, always screen doors and why they always hoover, clean, and spray the air with water.

Unlike a traditional building site, it’s not possible to saturate the air in people’s homes with water.

“It’s never ideal,” says Karl, “and being an ex–electrician myself, who’s rewired many a house, you always want to do more. Year on year as more information comes out about the harmful effects of dust, we’re increasingly aware of the dangers and want to do everything we can to prevent them.”

Which is why, when Karl was introduced to the XD One by Trolex MD Steve Holland, he was so keen to get it out on site to trial for dust detection. “What a wonderful idea!” says Karl. “It looks perfect.”

After all, what better way to instantly identify the dust threat than with accurate, real-time dust monitoring and readings? Even better that they’re available on wearable devices his team can just clip on as they work.

A real-time reading of the room designed not just to protect Thermatic workers but also to gain a clear understanding on dust levels that might impact on customers, too.

As important as the XD ONE Portable Dust Monitor is in protecting workers and tenants, using it also sends a very clear message to the industry, not just from Thermatic, but also from the main contractors Thermatic work for.

Very much a “we go above and beyond” message, any main contractor can be rightly proud to do their bit in helping to prevent the 12,000 deaths a year from workplace respiratory disease by using Thermatic and Trolex XD ONE Portable Dust Monitor.

It’s a pioneering approach in the construction industry that really prioritises health and safety and makes clear the commitment to worker and customer safety.

With the XD ONE now onsite as part of a pilot phase to monitor rewiring and upgrade projects, we’ll be reporting back very soon.

Says Karl, “I’m really looking forward to seeing what kind of data the XD ONE gives us, the degree of harm it detects and what we can do about it.”

In the meantime if you want any more information on how the XD ONE can keep your workers and customers safe from the dangers of avoidable dust and particulate inhalation get in touch today.

Have you heard of the ‘psychological contract’? It’s the unwritten understanding of the interaction between you, your workplace environment and your colleagues.

We all have a psychological contract with our employers, whether we know it or not.

As well as considering the physical aspects of your work environment, your psychological contract includes things like the quality of relationships you have with the people you work with, whether you feel properly listened to and understood and know what’s expected of you in your role.

An important part of that contract is ‘psychological safety’. How safe or unsafe your psychological contract leaves you feeling at work.

A term coined in 1999 by organisational behavioural scientist, Amy Edmondson, ‘psychological safety’ includes things like trust in your colleagues, your perception of physical threat in your working environment and how you feel about the training and support you get to do your job.

Unsurprisingly, the safer people feel at work, both physically and emotionally, the more productive they are.

By the same token, if people feel unsafe, then not only are they less productive, but the time the trouble and expense of having to replace people unhappy in their jobs is huge.

Employee benefits provider Perkbox estimates that ‘disengaged employees are costing the UK economy £340 billion every year in lost training and recruitment costs, sick days, productivity, creativity and innovation.’

So how can you make sure that people in your organisation feel psychologically safe?

The first important step in creating a psychologically safe workplace is to make it as physically safe as possible.

Speaking with Trolex, Occupational Psychologist Catherine Dobson told us, “If an environment is not physically safe, if it’s too hot, too cold, or if it feels too dangerous people feel stressed. We must ask ourselves how do we get the right environment for people with the right kind of training, the right kind of cooperation to make it healthier?

Which is what contributes to making our range of dust monitors, such an important development. These include the AIR XD Dust Monitor, the XD ONE Portable Dust Monitor – our wearable dust monitoring technology, and our AIR XS Silica Monitor for real-time silica dust monitoring.

Not simply because it protects workers from the physical dangers of inhaling lethal respirable dusts, but because armed with the knowledge that they are working safely, people feel psychologically safer too.

Catherine explains how: “In relation to silica and dust monitoring. Because the AIR XS Silica Monitor is new, there’s scope for demonstrating that it works. And people can see that.

Also, because all these dust monitors work in real time, it gives people the trust that an intervention will take place should they be in danger. They can trust in the environment being safe.”

A very good thing for workers on both a physical and emotional level.

And great news, too, for the mining, tunnelling, quarrying, manufacturing and construction companies invested in fulfilling their side of the psychological contract with advanced dust monitoring.

Businesses can then reap the rewards of improved production and better worker retention, so everybody wins.

Silica dust is a problem. A serious problem. In particular, respirable crystalline silica (RCS) – the minute respirable silica dust particles released when working with concrete, bricks, mortar, ceramics, MDF, plywood, stone, ceramics and other similar materials.

Invisible to the naked eye, and 100 times smaller than sand, RCS is fine enough to reach deep inside the lungs. Once there, it causes long term and often fatal damage through silicosis, heart failure, arthritis, kidney disease, Chronic Obstructive Pulmonary Disease (COPD) and even lung cancer.

In the UK, the IOSH reports that half a million workers are exposed to RCS. It contributes to 12,000 lung disease deaths a year – mostly among workers employed in construction or the manufacturing of products for construction.

And RCS isn’t a secret. It’s an acknowledged threat. The HSE (Health & Safety Executive) recognises it as ‘the biggest risk to construction workers after asbestos’ and The All-Party Parliamentary Group for Respiratory Health have released a damning report ‘Silica – the next asbestos’.

The main challenge in combating its dangers is the inherent nature of silica dust itself. The fact that it’s so small, and that as minute shards of irregularly shaped quartz, it’s so hard to detect. The small scale of the particles has made real-time RCS monitoring incredibly difficult, time-consuming, and expensive – which makes the scale of the problem even larger.

Typically, exposure monitoring for RCS has involved occupational hygienists setting up fixed location or wearable instrumentation, including a pump connected to a sampling head that collects samples on a filter. These samples are then sent off to a lab for analysis.

This exposure reporting is then used to determine whether control measures are effective or not and whether an area is safe to work in.

That’s clearly far from ideal.

Analysis is retrospective, reporting on working environments long after workers may already have been exposed to potentially lethal amounts of RCS and is inherently inaccurate. Also, because analysis needs to be carried out by H&S professionals, costs can quickly rocket, with analysis often totalling thousands of pounds a month – and that’s just per survey!

All of this makes the prospect of accurate, affordable, real-time RCS monitoring something of a “Holy Grail” when it comes to protecting workers from this deadly dust.

A Holy Grail that, with strong rumours of a significant breakthrough in silica monitoring soon to hit the market, we’re set to revolutionise RCS detection and the health and safety industry. Eventually, protecting countless workers from unnecessary exposure to potentially lethal silica.

Imagine that. No more clunky, costly, after-the-event analysis and guesswork. Just accurate, affordable, real-time silica monitoring – which will be available in just a few short months.

Curious?

As they say… watch this space.

Get in touch with one of our experts today to discuss how the AIR XS Silica Monitor can improve your safety processes.

It’s the twenty-first century, and we are in “the age of data”. Everything is data-driven from what we do and use. Even the devices we carry around with us all day, like our mobile phones, and most recently, even smart watches are mainly data tracking devices.

And whilst many are sceptical of how the data is used, realistically everyone is positively affected by modern data collection. Even if we don’t realise it, data today is allowing us to make educated changes to our lifestyle, finances, social lives and health.

It seems odd that a widely available resource such as data is taken for granted everyday, and isn’t used effectively to do the really important things more regularly – especially when it comes to saving lives and preventing life threatening illnesses.

Sadly, the global annual number of people dying from occupational respiratory illnesses is estimated at over 500,000. The critical question remains: are we using the data at our disposal to positively impact workplace health and safety? Probably not…

Firstly, we need to understand that data is critical, and a lack of its use is a problem. Real-time dust monitoring has long since been an expensive, complicated “black art” unavailable to the masses. Whilst monitoring isn’t a solution in itself, it’s pivotal to making the right decisions to ultimately save lives and understand where the risk really lies.

Gravimetric or “dust deposit” gauges have long been an industry standard, and a legislative medium for measuring harmful dust exposure; but they only give ‘one side of the story’ and even then a partial story at best. When it comes to saving lives, time is of the essence. Even more so early detection and real-time alarming typically results in prompt action.

This gravimetric data is not to be dismissed and is important, but let’s face it with global numbers of over 500,000 people still dying every year, it’s not enough. So how do we critically challenge the status quo?

Now imagine taking this combined average data over a time frame, and combining it with accurate, real-time, personal dust monitoring. Imagine the changes you could make to process, controls, procedures and culture by seeing when and how the exposure is caused, where it was unacceptably high and, maybe, even warning people in real-time who unknowingly enter into the dangerous zone of this invisible killer.

If a smoke alarm goes off, you leave the building regardless of whether you see the fire. Why shouldn’t we apply the same theory, conscious response and swift action to slow and painful killers such as respirable dust?

Exposure is commonly expected in mining or engineered stone industries, however many more are unsuspectingly exposed in construction, demolition, quarrying, manufacturing, and more generally those in support functions in nearby offices and facilities within these industries and even people regularly using non-dust controlled roads.

The sad thing is, if the danger isn’t obvious (and dangerous levels of dust often aren’t as the most dangerous particles are usually the invisible ones), it’s too easy to ignore until the damage is done.

With real-time data, it’s easy to make decisions on measures that need to be taken to understand personal exposure levels and even have real time exposure warnings. Trolex is giving the power back to the people, companies and regulators to make informed decisions about protecting themselves and each other in the interest of saving lives.

If this drives changes in monitoring requirements, engineering controls such as dust suppression or RPE regulations can only benefit people and the families of those people who are currently exposed, all whilst minimising the risk of future exposure, and building precedence for the application of effective dust control measures in the hierarchy of control.

Here’s another thing: as a business or a responsible person, real-time monitoring and control is not only affordable and simple, but also accessible to everyone.

So, the question is, can you afford to not understand the problem?

Our aim is to give people the information, to save lives and increase awareness, and if you want to know more about our real-time fixed, portable or personal dust monitors (AIR XD Dust Monitor, XD ONE Portable Dust Monitor or XD1+ Personal Dust Monitor) then get in touch today.