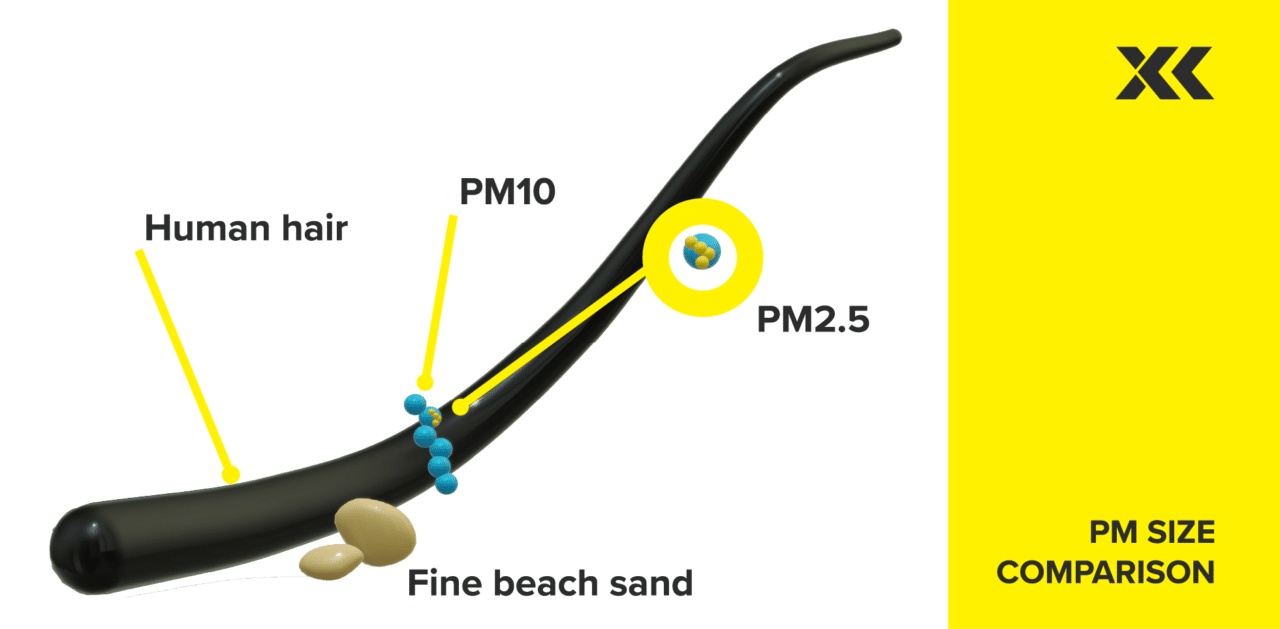

‘PM’ or particulate matter, also known as particle pollution is the term for a mixture of solid particles and liquid droplets found in the air.

It’s estimated that air pollution is linked to 43,000 deaths per year in the UK. Worldwide, at least 7 million people die each year from exposure to air pollution, with 91% of the worldwide population living in locations where the air quality exceeded the World Health Organisations (WHO) air pollution guidelines.

These guidelines state that that annual average concentrations of PM2.5 should not exceed 5 µg/m3 and PM10 should not exceed 15 µg/m3 (both for 24-hour periods). According to the WHO, ‘fine particulate matter at PM2.5 can penetrate through the lungs and further enter the body through the blood stream, affecting all major organs’. Exposure to dust at PM2.5 can cause serious disease to the respiratory system, such as lung cancer and COPD, and also can effect cardiovascular diseases, such as a stroke.

The image below demonstrates PM2.5 and PM10 size in comparison to a single human hair and a grain of sand.

The Department for Environment Food & Rural Affairs (DEFRA), the UK government ministerial department for environment protection, have also highlighted the severity of exposure to air pollution. This growing concern for the UK government estimated in 2010 that the cost of health impacts of air pollution was likely to exceed estimates of £8bn to £20bn.

Although between 2005 and 2022, the UK’s PM2.5 emissions decreased by 41%, emission levels have been relatively steady with small annual fluctuations in the last decade. Industrial combustion is a major source of PM emissions, as well as emissions from industrial production also playing a major part, which can be linked to heavy-dust industry where hazardous particulates can become airborne. Despite some reductions in PM emissions, the threat still very much remains.

A solution to this is real-time dust monitoring. Real-time particulate monitoring allows people in heavy dust loading environments, including industrial applications, to not only understand, but alert them instantaneously when they are exposed to dangerous levels of air pollution. For example, our AIR XD Dust Monitor can alert people in real-time when legislative levels of µg/m3 are breached, over a time-weighted average (TWA) 8-hour period, for both PM2.5 and PM10.

This technology not only offers a simple solution to individuals at high risk of exposure to air pollution by providing instant alerts, but also can help to prevent exposure in the future, as at-risk individuals can learn exactly when and where exposure to air pollution is highest and will likely occur. Thanks to real-time monitoring, both in the UK and Worldwide, we can reduce exposure to air pollution.

The AIR XS Silica Monitor leverages cutting-edge Optical Refraction Technology (ORT) to enhance workplace safety by providing real-time monitoring of respirable crystalline silica (RCS). Unlike traditional particle monitors, AIR XS distinguishes and measures RCS content, enabling immediate detection and response to harmful silica dust levels. This technology is crucial in combating occupational lung diseases such as silicosis, which affects millions of workers globally.

Current monitoring methods, like gravimetric sampling, are time-consuming and often deliver results too late to prevent exposure. In contrast, real-time silica monitoring offers immediate data, significantly reducing the risk of occupational silicosis by enabling prompt action to mitigate hazardous conditions. The importance of such real-time data is highlighted by cases like Joanna McNeill’s, who developed silicosis at the age of just 36. Her story, like many others underscores the necessity for continuous monitoring to protect workers from the threat of silicosis, regardless of their occupational environment.

Our real-time RCS monitor, AIR XS provides a real-time solution to this threat. Workers are not only alarmed and alerted when silica levels exceed legislative limits but can work to best practices by implementing AIR XS with the Hierarchy of Controls, supporting proactive measures to eliminate or minimise exposure to RCS. This move to real-time monitoring as a solution to the threat of silicosis has also been noticed by governing bodies, like the All-Party Parliamentary Group on Respiratory Health.

To learn more about how this real-time solution not only enhances worker safety but also streamlines business operations, click the link below to read the case study in full.

We’re excited to bring to the market our XD1+ Personal Dust Monitor as a connected dust monitor with the Reactec Ecosystem.

The Reactec Ecosystem for workplace exposure to hazards includes an IoT gateway, Reactec’s workplace wearable RASOR for secure data transmission, an RFID identity card to personalise the collected dust data and the cloud-based Reactec Analytics software for informative and automatic data dissemination.

RASOR is a communications gateway with integrated SIM and GPS technology to gather data seamlessly from the XD1+ and present it live, personalised and position tracked data to remote line managers via a browser.

Our XD1+ Personal Dust Monitor can be easily connected with RASOR in two different modes for both single worker use and for pairing a number of XD1+ devices to a RASOR connected in hub mode, allowing for flexibility when working, but still providing vital information of worker exposure which can be analysed and interrogated on Reactec’s Analytics platform.

By leveraging revolutionary real-time personal monitoring technology with location tracking, automatic data collection and powerful data analytics, employers can now control their worker’s exposure to harmful respirable dust like never before and reduce these occupational diseases thanks to connected XD1+ and Reactec Ecosystem.

Check our guide for details on the key modes of pairing XD1+ with the Reactec Ecosystem, a run-through of how to connect your XD1+ in these different modes and the benefits of each type of connectivity.

A manufacturer of prestigious natural stone, Burlington Stone have quarried for over 200 years across the English Lake District, extracting and crafting a diverse range of signature British natural slate and stone products.

Individuals across their workforce are often exposed to hazardous substances, most notably airborne dust, including silica dust. Burlington Stone trialed two XD1+ devices on their site for a month to see how real-time, personal dust monitoring would improve their safety processes.

After the trial, we spoke to Health and Safety Manager, Peter Walker, about the success of the trial and some of the major benefits which Burlington Stone’s workforce found deploying XD1+ Personal Dust Monitor units in their day-to-day processes.

Launched in 2022, the AIR XS Silica Monitor isn’t like other silica monitors on the market. If you’ve been in the Health and Safety space, it’s likely you’ll know about Optical Particle Counter (OPC), also known as “light-scattering”; but our patented AIR XS isn’t just another OPC.

Unlike traditional Optical Particle Counters (OPCs) that rely on light scattering and interruptions to deduce particle size and quantity, the patented Optical Refraction Technology (ORT) used in the AIR XS shines a laser through each particle, capturing its refraction on multiple sensors.

In our blog below, we reference Pink Floyd’s 1973 album Dark Side of the Moon to explain one way to how ORT works. It’s not exact by any means but the refraction of the light coming out of the prism shows an example of how light refracts, similar to a crystalline particle.

Did you make it to the BTS 2020+1 Conference and Exhibition in London at the end of September? 800+ tunnelling professionals in attendance and 55+ global tunnelling brands exhibiting over two days of serious tunnel talk.

If you did, then you’ll probably be aware that while discussions amongst tunnelling design, construction, and operation and maintenance professionals were initially concerned that the number of UK tunnelling projects seem to be in decline, what actually emerged from the event was a feeling of optimism.

With more London Underground projects in the pipeline, other UK underground train projects planned and talk turning to creative ways that tunnelling can be used to mitigate the effects of climate change – what began as a rather gloomy outlook soon turned far more positive as the conversations turned to fresh opportunities.

Take the scale and success of Toronto’s PATH for example. This gargantuan tunnelling project includes:

Constructed over the last 100 years to allow the city to function successfully in the face of bitterly cold winters with huge volumes of snowfall, PATH shows that there’s clearly potential for innovative problem solving to create similar underground living, working and socialising environments.

Instead of protecting people from the effects of extreme cold, new designs might protect us from extreme heat as the climate emergency gathers pace.

Internationally approved and certified, the Sentro 8 is designed to function in the world’s most dangerous working environments, allowing you to scan for up to eight different gases simultaneously.

In short: All the detection you need for complex mining and industrial applications in a single device.

Group 1 IS (intrinsically safe) compliant – low power consumption, zero sparking and certified for the most dangerous of industrial environments, the Sentro 8 protects your workers from a broad range of environmental threats and also alerts you to ambient changes.

When safety demands that you monitor for multiple gasses or other environmental conditions – all at the same time – use the Trolex Sentro 8.

Whatever the challenge. Wherever in the tunnelling world that challenge exists. Whenever in the future that challenge presents itself – we’re ready to take it on – to protect your workers from dangerous gases and particulates and to make tunnelling as safe as it can possibly be.

Contact us today using the contact form below and we’ll tell you everything you need to know about real-time toxic and flammable gas detection and how to keep your people safe on your next tunnelling project.

When it comes to occupational health and safety, new real-time dust monitoring such as the XD ONE Portable Dust Monitor can help to make decisions for the hierarchy of controls.

In this e-book we explain how the arrival of affordable, real-time monitoring, and both wearable and portable dust monitoring technologies promote this new awareness of the dangers of dust in a far broader range of working environments.

Employers and the health and safety community are now shifting their attention. Where they’ve traditionally focused on safety, they now look at the major impacts on long-term health associated with working in hazardous environments.

There’s also an increasing awareness of the range of industries that can present long-term health hazards through the inhalation of dangerous dust particles, from traditional industrial environments to commercial activities.

The HSE are reporting an estimated 1.4 million people in the UK report ‘lung or breathing problems that were caused or made worse by work’ – and whilst it’s great that people are starting to pay more attention to this issue, there’s plenty of room for improvement.

Whilst financial costs of lung diseases effect both businesses and individuals, respiratory diseases are more than just an economic drain. It’s a personal tragedy, and there are a whole raft of occupations and jobs where people are exposed to dangerous dust across the world.

However, through the hierarchy of controls, businesses can determine the most effective solutions in order to keep workers protected from dangerous dust exposure.

Knowing that dangerous dust exists, knowing its effects are potentially lethal, and knowing that the damage it causes is preventable, only takes you so far. Knowing how to prevent that harm is what matters, and this is how the hierarchy of controls can help businesses become more efficient, by understanding how effective each method is in benefitting the workforce.

Fortunately, new accurate, real-time, fixed, wearable and portable dust and silica monitoring sensors are leading the detection charge across every use case. By precisely reading the real-time dust load in any given environment, and the enemy now ‘visible’, businesses can begin to apply the hierarchy of controls in a far more meaningful way.

An independent UK agency responsible for the encouragement, regulation and enforcement of workplace health, safety and welfare, and for research into occupational risks in Great Britain, carried out a series of tests on three XD One Portable Dust Monitor units.

They compared them to the following dust monitors: Casella CEL-712 Microdust Pro, a Thermo Scientific MIE Personal DataRam (pDR) 1500, a TSI SidePak AM510.

The key elements of the testing were as follows:

The results from the independent testing demonstrated that the XD ONE performs better than other personal dust monitors on the market. There were five critical messages from the testing as outlined below:

It’s one thing claiming to design, develop and manufacture the world’s most accurate, easy to maintain, and best value wearable dust monitoring device – which we do.

But substantiating that claim?

Backing it up with the facts, with independent verifiable research? Field testing our device and comparing it like-for-like with other similar products to prove our point – is that even possible?

It certainly is.

We can prove that the XD ONE Portable Dust Monitor is the world’s leading wearable dust monitoring system.

Courtesy of The HSE – a completely independent UK Government compliance body and one of the leading organisations of its type in the world – who recently completed a series of dust monitoring tests.

Their tests compared three XD ONE units (to capture a reliable spread of results) with three other commercially available personal dust monitors.

To measure the mean respirable and inhalable dust concentrations, two gravimetric samplers were also tested against the Trolex XD ONE – The GK 2.69 cyclone (BGI by Mesa Labs) and the IOM inhalable sampler (SKC Inc.).

Using Arizona Road Dust, the preferred type of dust for dust monitor trials, testing was undertaken in a 1 m x 1 m x 3 m calm air chamber, at three different dust concentrations – low 2 mg/m³, medium 5 mg/m3, and high 11 mg/m3.

At the medium and highest concentrations, the test lasted for 60 minutes. At the lowest concentration, the test lasted for 120 minutes to make sure enough dust was sampled by the gravimetric samplers to achieve a reliable reading.

Dust concentration was tested in three steps (20 minutes at each stage) from the lowest to the highest. Once at the maximum, the concentration was stepped back down to zero at the same rate.

In a word… impressive.

Saving lives and protecting workers’ health by preventing dust inhalation is a serious business. And so too is putting our technology and our reputation on the line against much bigger and better funded competitors, and vastly more expensive products.

The HSE testing provided a clear endorsement of our ‘marker leader’ claim. But it went further still. Taking into account the XD ONE’s size and weight, cost, ease of set up and ease of maintenance, the tests underlined its practical, performance and competitive advantages in the most emphatic terms.

The results speak for themselves.

When faced with a rational decision between the XD ONE and a competing product – the choice is crystal clear. You’d choose the XD ONE every time.

Working with distributors and partners overseas is how we gain exclusive access to the businesses that need our products to save the lives of their employees.

We value our close partners as much as our own employees and have good relationships that last way beyond the business transaction. This includes trusting our partners to demonstrate our new technology to their customers, in mutual understanding, so our partners and their customers can get ‘up close and personal’ to our XD ONE Portable Dust Monitor and can try it out for themselves in a real-life environment.

Our Belgium, Netherlands and Luxemburg (BeNeLux) distributor, BASystemen, ordered six XD ONE demo units to give to their customers to trial. They landed a few days ago, and their directors are already behind our campaign to get these monitors into the hands of every worker who needs one, and to start saving lives straight away.

Khoa Nguyen is a keen advocate of field trails, and comments ‘we love feedback!’ He intends to lend them out to his customers so they can ‘try out all functionalities’.

The dust monitors themselves have been met with great praise and Khoa says, ‘We truly believe that the XD ONE Portable Dust Monitor is a nice solution to the market needs for a portable dust monitor, which is simple to use, reliable and cost effective’. He adds, “…size is great, weight is perfect and very easy to use.”

Khoa is happy with our partnership, and concludes by saying, “Response is quick and partner conditions are good so both parties benefit long term” and suggests that as a company, BASystemen can “definitely learn from this.”

If you’re a distributor and would like to request demo units of the XD ONE Portable Dust Monitor, please get in touch today.