With an estimated 1 million people dying globally from the inhalation of dust in occupational environments every year, now is the time to protect your workers. Personal and portable dust monitoring provides a simple solution for all workers at risk of dangerous dusk regardless of their application, processes or industry.

We’re continuously innovating our real-time dust monitoring technology to give you access to the information to effect change and keep your workers safe from hazardous respirable dusts. Which is why we have developed the XD1+ Personal Dust Monitor and the XD ONE Portable Dust Monitor.

Both products provide a unique approach to personal, handheld, portable dust monitoring. It’s dust monitoring that doesn’t get in the way, that’s small and versatile enough to give you the freedom to do your job whilst making zero compromise on accuracy and reliability, remaining easy to use, simple to maintain and cost effective.

Real-time monitoring offers solutions to us in our everyday lives. Whether it’s the real-time alerts that tells you that you’re at risk or in danger, or the subsequent data which provides you accurate information on what you’re monitoring, real-time monitoring has become an essential part of our lives.

But what about real-time monitoring when it comes to enhancing the workforce? You’d rely on real-time monitoring and alarms to tell you there’s a fire in your home, so why wouldn’t you rely on real-time monitoring to tell you if you were a risk as serious to your health at work? You’d rely on real-time data to tell you if you needed to track nutrition or health trends, so why wouldn’t you rely on essential data in real-time in the workplace?

Whether it’s for the health and safety of you and your colleagues, to better understand the processes and efficiency of the business, or just to help aid decisions, real-time monitoring can provide valuable data to workforces across a whole range of industries. Whether you are monitoring for hazardous substances like dust or silica, or monitoring for HAV, sound levels or proximity measures, real-time monitoring can enhance your workforce.

The connected XD1+ Personal Dust Monitor and Reactec cloud-based analytics platform has arrived. The Reactec Analytics platform brings exposure data from the XD1+ to life by delivering real-time updates from individual workers and tracking respirable data to determine where the highest concentration of harmful dust exists in your workplace.

With no filters, pumps, tubes, or replaceable parts, the XD1+ Personal Dust Monitor is one of the most compact, lightweight, and easy-to-use real-time personal dust monitors on the market. For such an accurate and reliable unit, it is also essential to be able to access and easily understand the data which the XD1+ is picking up, minute by minute.

Reactec’s cloud-based analytics platform brings XD1+ exposure data to life by delivering real-time updates from individual workers to remote supervisors, whilst tracking respirable data, to determine where the highest concentration of dust exists in your workplace.

With the support of Reactec’s Ecosystem, the XD1+ is transformed into a connected, personalised dust monitoring device that shares invaluable data insight to key stakeholders and figureheads. The XD1+ is integrated into the Reactec Ecosystem using the Reactec RASOR device as an IoT Gateway to Reactec’s powerful A=nalytics software.

By simply connecting your XD1+ unit to the Reactec Analytics platform you are able to:

Silicosis is now the most common occupational lung disease in the world, with silica dust described as ‘the new asbestos’ due to the extreme threat it poses to human health.

Silica dust (respirable crystalline silica (RCS)) is extremely harmful to human health due to its physical and biological properties.

It affects around 50,000,000 workers in a wide variety of industries all around the world and prolonged exposure leads to silicosis and a wide range of other diseases, most of which are untreatable and often lead to long-term disability and/or death.

The potential for harm is even worse than that when you consider that asbestos is one of many different silica compounds and silica is the most proliferate mineral on earth; present in bricks, sand, stone, concrete, glass, cement and many other construction and building materials. 99% of deaths in occupational settings, are caused by the inhalation of dangerous particulates, with the other significant factor in this statistic being the extreme difficulty in monitoring in real-time for these killer particulates

It has never been possible to reliably detect and distinguish silica dust in real time in the real-world settings in which workers are exposed to it – until now.

The white paper looks at the background of silica exposure, the current methodologies employed to monitor it and the new technological advancement that has led to the development of a field-ready product for the first time in history.

Legislated limits of exposure have been tightening up in most major economies as the harm being caused becomes known, but reductions in limits and the implementation of these limits have been hampered by the lack of real-time accurate and reliable monitoring capability.

This technology has the potential to change the way industry, governments, businesses and workers themselves respond to the threat of RCS exposure in the workplace, and as such, it can be the beginning of the end for occupational silicosis. Not only does it improve health and safety outcomes for frontline workers, but it also reduces costs for businesses whilst giving them back control over their working environment.

Perhaps most importantly of all, it gives legislative bodies the tool they need to create and implement workplace exposure limits (WELs) that genuinely protect workers from harm, at a cost industry can bear, ending decades of debate over what the limits should be and how practicable it is for industry to meet them.

In 2020, the All-Party Parliamentary Group for Respiratory Health (APPG) issued the report “Silica, the next asbestos?”, which examined the disproportionate effect of silica dust to construction workers’ lives.

Since the publication of that report, the APPG were contacted by a number of experts on the subject matter, who highlighted the advances in risk reduction and the particularly promising rise of real-time dust and silica monitoring technology.

“Trolex believe that the most obvious and immediate benefit of real-time monitoring is in improving safety for those potentially exposed to silica in the workplace.”

The new, revised report, titled “Improving Silicosis Outcomes in the UK” also explored these new silicosis prevention strategies, including some input from Trolex on the subject matter. From this, the APPG raised several clinical and regulatory recommendations to protect workers from the dangers of occupational silicosis going forward.

“We recommend that the Health and Safety Executive (HSE) assesses and determines the data and technology needed to allow the UK to reduce the WEL for work with silica to 0.05mg/m3.”

The recommendations from the APPG’s report indicate a number of changes need to be made in order to improve safety across all UK industries which use silica. These recommendations focus on both ways to prevent exposure to dangerous respirable crystalline silica (RCS) in the workplace, including improvements in education, real-time monitoring and reducing exposure limits, as well as improving health and support for those who currently suffer with silicosis.

“We recommend that the HSE actively considers and consults with industry on the positions of real-time monitoring to complement the hierarchy of controls.”

The UK’s favourite DIY and home improvement expert, Tommy Walsh, is calling for more to be done to protect workers from the dangers of silica dust.

Tommy believes that the issue of air quality on building sites should be a national concern, and that silica dust should be viewed the same way as asbestos.

While he became aware of the dangers of silica dust as an issue around five years ago, in relation to the disposal of plasterboard, Tommy says that he has not heard the issue discussed on building sites. This is in spite of the fact that 81% of those regularly exposed to silica dust are construction workers.

Tommy shared that the majority of health and safety concerns on smaller building sites are focused around obvious, external risks, such as falling from a ladder, electricity and water. As a result, he believes that more needs to be done to raise awareness of “invisible” risks, such as occupational silicosis, which is the most common chronic lung disease in the world.

He continued, “over half of the country’s construction is done by small builders and ‘one-man-band’ outfits. Air quality has always been a secondary concern to them, as they don’t know enough about it. Everyone would rather work safe than not safe, but they can’t do that if they don’t have the awareness. Health and safety can often be ignored due to cost-saving, time-saving, or ignorance, but if we can normalise the importance of air quality it will make it harder to ignore.”

Recent data has shown that respirable crystalline silica (RCS) is the biggest risk to construction workers after asbestos, with cases and exposure rising year on year. There are 12,000 deaths a year in the UK from inhalation of dust including silica in the workplace, opposed to just 142 recorded due to workplace accidents between 2020/2021. What’s more, there are an estimated 50,000 workers worldwide exposed to silica dust.

The scale of the issue is not matched by the awareness and action needed to prevent it.

Silicosis, as well as being the world’s most common occupational lung disease, can increase a person’s risk of tuberculosis, kidney disease, arthritis, and lung cancer. The consequences of occupational silicosis have been estimated to cost employers in the UK construction industry over £1 million per year.

In order to raise awareness and protect construction workers from this entirely preventable disease, we’ve launched the AIR XS Silica Monitor, the world’s first real-time silica monitor, which can provide real-time data of dangerous silica dust particles workers are exposed to across any given day.

Requiring no complicated set-up and only five minutes of maintenance a month, the AIR XS is easy-to-use and provides accurate, real-time RCS monitoring with minimal training, letting workers know if the amount of RCS content in their workspace is increasing as they work and when it has risen to dangerous levels.

Protecting the health and safety of the people who work for you is the ethical thing to do. It also makes good business sense as your people are your greatest asset.

But even if you aren’t driven by a moral or financial imperative, governments around the world are toughening up on the legislation that protects workers, so it’s not something any business can afford to ignore.

While some threats are obvious, others are invisible and incredibly hard to accurately detect, such as the deadly silica dust that are the by-product of many industries and manufacturing processes.

Silica dust is linked with severe health problems. It has been dubbed the ‘new asbestos’ and has already been the subject of litigation. Yet it’s something that has historically been impossible to monitor in real time.

Our Construction Industry Health and Safety Survey Winter 2021 shows that employers are concerned about safety, with nine out of 10 respondents recognising that worker safety is important or very important.

But it also revealed that on the ground it can be hard to meet the health and safety challenge, particularly when it comes to dust monitoring, which for a fifth of respondents accounted for half of their safety budget.

This in-depth report looks at how real-time, wearable dust monitoring technology can help to solve the issues from the findings of the Construction Industry Health and Safety Survey Winter 2021.

The findings ultimately mean that it’s clear we need a new approach to dust monitoring. One that looks to the future and is inspired by the intelligent tech revolutionising every other aspect of our lives.

It’s time to act now to tackle danger of hazardous dusts, like silica dust, by investing in smarter solutions to protect the air we breathe, with real-time dust monitoring.

Silica dust is the new asbestos.

But what if it’s not? What if there’s really nothing new about silica dust in relation to asbestos?

The link between the two is even closer than you may think…

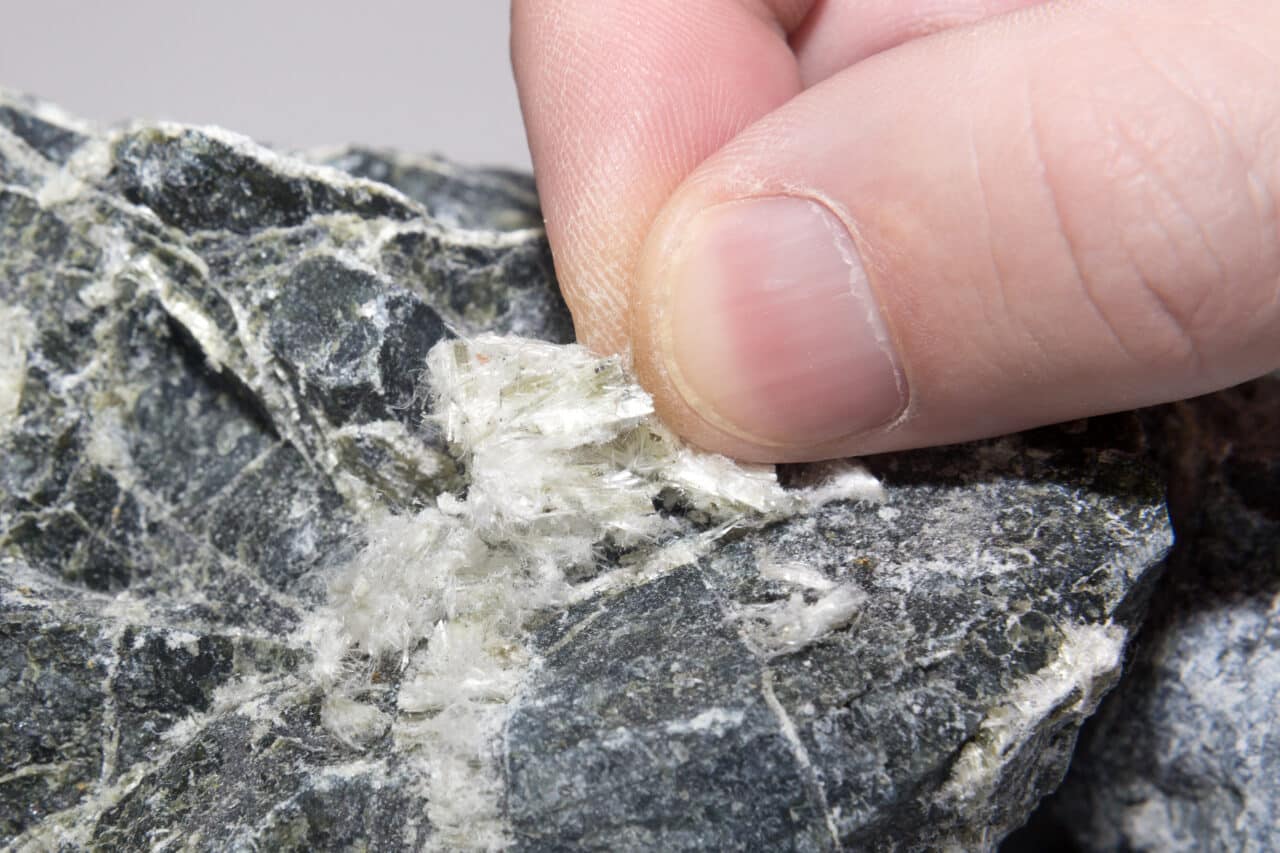

Most people know asbestos as the dangerous insulator used in construction, responsible for over 5,000 related disease-deaths per year, typically lung cancer and asbestosis.

However, in its natural form, asbestos is a naturally occurring fibrous silicate mineral.

Put simply, silicate minerals make up asbestos fibres.

Asbestos is actually just one of the many different forms of silicate materials, in the same way that silica dust is.

The similarities between silica dust and asbestos are much closer than people are aware of.

There is a different attitude towards asbestos compared to silica dust.

The dangers of exposure to asbestos are well documented.

Exposure to asbestos can cause serious lung conditions, including asbestosis and mesothelioma. It is the number 1 cause of recorded work-related deaths in the world.

Most people in the UK are aware of its dangers, particularly as asbestos was banned in 1999 for construction work in the UK.

Yet despite all of this, very few people are aware of how dangerous exposure to silica dust is, despite the fact that asbestos fibres are made up of silicate materials, in the same way silica is.

There are many more dangers relating to silica dust than people may be aware of.

Imagine you are working on refurbishing your bathroom and from the grinding of the ceramic sink and a load of dust becomes airborne.

If you were told that this airborne dust which you were inevitably inhaling was asbestos, you’d probably run a mile, right?

And who could blame you? A dust which is responsible for approximately 90,000 asbestos-related diseases per year. You’d want to get as far away from it as possible.

Well, it’s likely that that dust in your bathroom would in fact be silica dust.

A dust which is made up of silicate materials in the same way asbestos fibres are. A respirable dust which is just as lethal, if not more lethal, in comparison to asbestos dust.

But because it isn’t known to people as being the same as asbestos, the dangers seem to be less of a concern to people.

It’s time to get real and become aware of just how dangerous silica dust is.

It is reported that, in crystalline form, respirable crystalline silica (RCS) is responsible for the death of 600 people per year in Great Britain with 450 of those to workers in construction industry. What’s more, an estimated 50,000 workers are exposed to silica dust globally.

The importance of the dangers of silica dust must be realised, especially with what is known about how dangerous asbestos is.

Asbestos is just as lethal as silica dust. The dangers are the same, yet we cannot afford for the results of exposure to silica dust to be the same as what occurred with asbestos.

Silica could be as lethal as asbestos, if not more so, with equally serious consequences.

Being aware of the issue is the start, action must be taken to protect workers from this dangerous dust.

We cannot afford to let history repeat itself.

New studies from charity ‘Asthma and Lung UK’ (ALUK) found that lung disease deaths in the UK are the highest in Western Europe.

The staggering statistics have prompted an expanded approach towards research and development of lung diseases from ALUK.

ALUK’s studies show that cases of lung disease related deaths in the UK have been on the rise for the past 20 years.

It is reported that 500,000 people in the UK died from deaths relating to lung diseases over a seven-year period.

In 2018 alone, 84,721 respiratory deaths were recorded in the UK.

The charity has described the state of lung health in the UK as ‘shameful’, stating the need for improved research and development solutions to the problem.

After its relaunch in February, ALUK established a new five-year strategy upon the results of the study.

Lung diseases are currently the third most common cause of death in the UK and it’s currently costing the NHS £9 billion every year.

Despite this, lung-related health care is receiving less than 2% of public funding.

It is evident that the seriousness of lung problems in relation to other diseases is not taken as seriously, despite what we are seeing from the data.

A predominant factor in the poor state of the nation’s lung health is that people believe lung conditions aren’t life-threatening. This is a major misconception.

Through spreading awareness of how ‘shameful’ lung health is in the UK, this misconception can be dispelled.

ALUK aim to reduce lung disease deaths by 20% by 2027. When making everyone aware of these gruesome statistics, this can become a possibility.

The end goal is to provide support for everyone effected by all forms of lung disease.

ALUK’s solution to achieving this goal is through research and innovation.

Their aim is to expand their research and innovation programme so that £5 million is being invested into relevant research each year.

With the aim to “develop at least three new self-management tools” for 2 million people suffering with lung diseases, ALUK want to make training programmes and essential advice easily accessible to those who need it.

“By 2027, we will give 80% of people with lung conditions the opportunity to access our network of Breathe Easy support groups” states the ALUK Strategy to 2027.

With this, the strain on public healthcare is minimised and individuals are able to monitor their personal health through digitalised platforms and shared networks.

The statistics right now make for harrowing reading and harsh truths.

However, for ALUK, research and innovation is the solution for the future. By identifying the problem and acknowledging its severity and scale, goals can be achieved.

Through effective research and innovation lung disease deaths can become a thing of the past, not just in the UK, but worldwide.

Trolex are excited to be partnered with Active Environmental Solutions (AES), working together to protect workers from the dangerous and often irreversible consequences of occupational lung diseases caused by dust inhalation.

With AES’s specialist knowledge of occupational health and safety in Australian industries and Trolex’s leading safety technology, the opportunity of delivering solutions to prevent the dangers of dust inhalation for Australian workers, is not just a possibility, but now a reality.

AES want to spread awareness of the dangers of occupational lung diseases caused by dust inhalation. And in the case of dust monitoring, spreading awareness that new real-time dust monitoring technology to help prevent lethal occupational respiratory diseases now exists.

The opportunity to partner with Trolex was welcomed by AES, as it means that they can merge their expertise in occupational health using Trolex’s leading safety technology.

This creates the best solutions to their respective industries.

This simple message appealed to AES, and to Aleks Todorovic MSc, (OHP), Managing Director of AES’s team of Australian Occupational Safety experts at AES, as it aligned perfectly with the workers they seek to protect:

“Many businesses intuitively know the benefit of a broad threat detection – they just don’t know they know it, or perhaps how they go about implementing such devices – it’s our job to awaken that knowledge and show them there are new and effective dust detection technologies such as the Trolex AIR XD Dust Monitor, the XD ONE Personal Dust Monitor and most recently, the AIR XS Silica Monitor.

There are no arm twisting, or heavy sales techniques involved. Just a clear and simple presentation of responding to the facts.

Which is why Trolex and AES are working hard to provide further education to Australia’s mining, tunnelling, quarrying and construction industries, where workers are exposed to dangerous forms of respirable dusts.

This common goal of providing and expert knowledge and specialist equipment to these industries is the drive needed to inevitably reduce instances of occupational lung diseases to save lives.

Now, this collaboration will help to do exactly that.

The approach taken by businesses within these industries must now change. With new legislation on exposure to harmful dust in Australia, new dust monitoring methods are needing to be implemented.

Aleks said “As an occupational hygiene-minded business we know only too well the devastating effects inhaling respirable dusts can have on people’s long-term health.”

“That’s why we’re invested in the success and distribution of new and effective real-time dust monitoring technologies such as the Trolex AIR XD Dust Monitor, the XD ONE Portable Dust Monitor and the AIR XS Silica Monitor. These are lifesaving technologies that need to be included in their safety thinking” stated Aleks further.

By using Trolex’s advanced dust monitoring technologies, small changes can have a huge impact.

As the war on silica dust grows ever stronger by the day, more needs to be done.

With the reduction in exposure limits coming into effect across Australia, particularly hard on respirable crystalline silica (RCS), real-time monitoring for silica dust is a necessity, retaining live data and providing an instant alarm the legislated threshold is breached.

Whilst the ability to retrospectively assess levels of silica dust in facilities is available to industries where deadly silica dust is prevalent, the ability to monitor for silica dust in real time is not.

Trolex’s all new real-time silica monitor, the AIR XS, allows for accurate and reliable results demonstrating compliance with legislation. Aleks commented on this world-first technology:

“We are really excited to be a part of this project to be able to detect silica in real time. This will be the world’s first monitor to have this capability and we’re proud to be distributing it throughout Australia. The project was produced with the support of the Centre for Work Health and Safety in NSW proving just how important and potentially life-saving the new technology will be.”

And with the talk of real-time, wearable silica monitoring devices a possibility in the future, of course it makes perfect sense for all industries to be increasingly focused on detection possibilities.

Together, Trolex and AES are providing real solutions for real problems in Australia.

If you’d like to speak to one of our experts about integrating real-time dust monitoring technology into your working environment, then you can use the contact form below to get in touch with one of our experts today.