With an estimated 1 million people dying globally from the inhalation of dust in occupational environments every year, now is the time to protect your workers. Personal and portable dust monitoring provides a simple solution for all workers at risk of dangerous dusk regardless of their application, processes or industry.

We’re continuously innovating our real-time dust monitoring technology to give you access to the information to effect change and keep your workers safe from hazardous respirable dusts. Which is why we have developed the XD1+ Personal Dust Monitor and the XD ONE Portable Dust Monitor.

Both products provide a unique approach to personal, handheld, portable dust monitoring. It’s dust monitoring that doesn’t get in the way, that’s small and versatile enough to give you the freedom to do your job whilst making zero compromise on accuracy and reliability, remaining easy to use, simple to maintain and cost effective.

With an estimated 1 million people dying globally from the inhalation of dust in occupational environments every year, now is the time to protect your workers. Real-time dust and silica monitoring provides instant alarms and alerts for all workers at risk of dangerous dusk regardless of their application, processes or industry.

We’re continuously innovating real-time dust monitoring technology to give you access to the information to effect change and keep your workers safe from hazardous respirable dusts. With a range of dust and silica monitoring options, we’re here to help you protect your workers.

Whether that’s heavy-duty area monitoring for high dust loading environments, personal dust monitoring for individual monitoring needs, or silica monitoring for working environments with high respirable crystalline silica (RCS) content, such as stonemasonry, tunnelling or quarrying.

Real-time monitoring offers solutions to us in our everyday lives. Whether it’s the real-time alerts that tells you that you’re at risk or in danger, or the subsequent data which provides you accurate information on what you’re monitoring, real-time monitoring has become an essential part of our lives.

But what about real-time monitoring when it comes to enhancing the workforce? You’d rely on real-time monitoring and alarms to tell you there’s a fire in your home, so why wouldn’t you rely on real-time monitoring to tell you if you were a risk as serious to your health at work? You’d rely on real-time data to tell you if you needed to track nutrition or health trends, so why wouldn’t you rely on essential data in real-time in the workplace?

Whether it’s for the health and safety of you and your colleagues, to better understand the processes and efficiency of the business, or just to help aid decisions, real-time monitoring can provide valuable data to workforces across a whole range of industries. Whether you are monitoring for hazardous substances like dust or silica, or monitoring for HAV, sound levels or proximity measures, real-time monitoring can enhance your workforce.

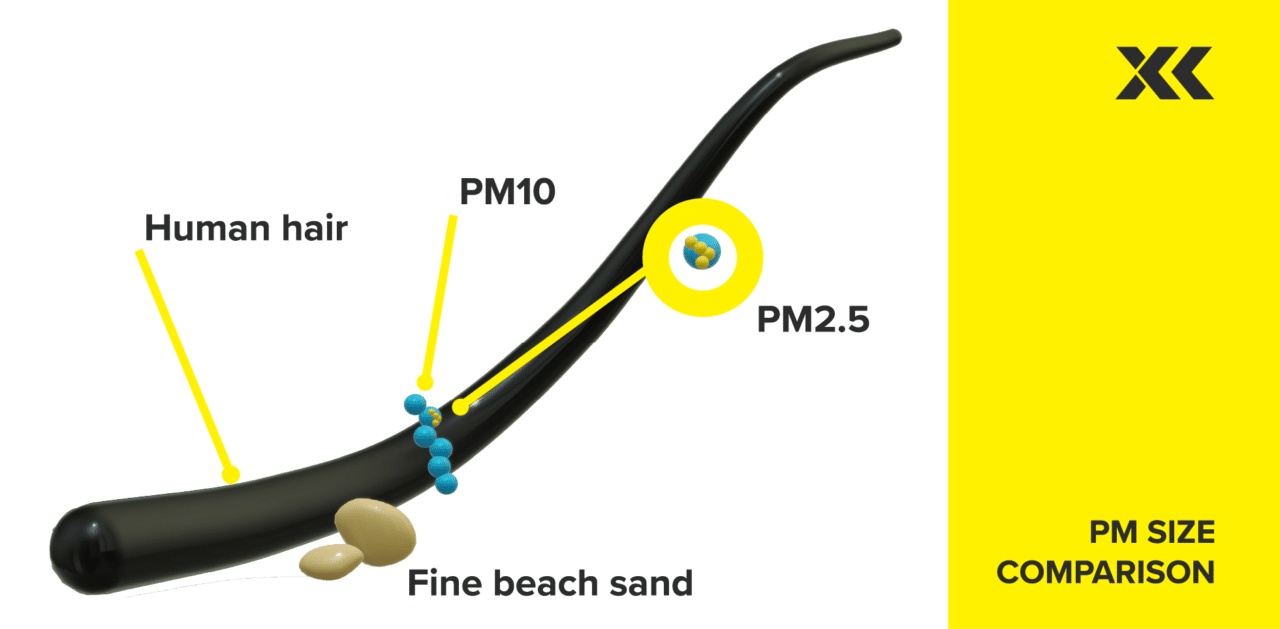

‘PM’ or particulate matter, also known as particle pollution is the term for a mixture of solid particles and liquid droplets found in the air.

It’s estimated that air pollution is linked to 43,000 deaths per year in the UK. Worldwide, at least 7 million people die each year from exposure to air pollution, with 91% of the worldwide population living in locations where the air quality exceeded the World Health Organisations (WHO) air pollution guidelines.

These guidelines state that that annual average concentrations of PM2.5 should not exceed 5 µg/m3 and PM10 should not exceed 15 µg/m3 (both for 24-hour periods). According to the WHO, ‘fine particulate matter at PM2.5 can penetrate through the lungs and further enter the body through the blood stream, affecting all major organs’. Exposure to dust at PM2.5 can cause serious disease to the respiratory system, such as lung cancer and COPD, and also can effect cardiovascular diseases, such as a stroke.

The image below demonstrates PM2.5 and PM10 size in comparison to a single human hair and a grain of sand.

The Department for Environment Food & Rural Affairs (DEFRA), the UK government ministerial department for environment protection, have also highlighted the severity of exposure to air pollution. This growing concern for the UK government estimated in 2010 that the cost of health impacts of air pollution was likely to exceed estimates of £8bn to £20bn.

Although between 2005 and 2022, the UK’s PM2.5 emissions decreased by 41%, emission levels have been relatively steady with small annual fluctuations in the last decade. Industrial combustion is a major source of PM emissions, as well as emissions from industrial production also playing a major part, which can be linked to heavy-dust industry where hazardous particulates can become airborne. Despite some reductions in PM emissions, the threat still very much remains.

A solution to this is real-time dust monitoring. Real-time particulate monitoring allows people in heavy dust loading environments, including industrial applications, to not only understand, but alert them instantaneously when they are exposed to dangerous levels of air pollution. For example, our AIR XD Dust Monitor can alert people in real-time when legislative levels of µg/m3 are breached, over a time-weighted average (TWA) 8-hour period, for both PM2.5 and PM10.

This technology not only offers a simple solution to individuals at high risk of exposure to air pollution by providing instant alerts, but also can help to prevent exposure in the future, as at-risk individuals can learn exactly when and where exposure to air pollution is highest and will likely occur. Thanks to real-time monitoring, both in the UK and Worldwide, we can reduce exposure to air pollution.

The AIR XS Silica Monitor leverages cutting-edge Optical Refraction Technology (ORT) to enhance workplace safety by providing real-time monitoring of respirable crystalline silica (RCS). Unlike traditional particle monitors, AIR XS distinguishes and measures RCS content, enabling immediate detection and response to harmful silica dust levels. This technology is crucial in combating occupational lung diseases such as silicosis, which affects millions of workers globally.

Current monitoring methods, like gravimetric sampling, are time-consuming and often deliver results too late to prevent exposure. In contrast, real-time silica monitoring offers immediate data, significantly reducing the risk of occupational silicosis by enabling prompt action to mitigate hazardous conditions. The importance of such real-time data is highlighted by cases like Joanna McNeill’s, who developed silicosis at the age of just 36. Her story, like many others underscores the necessity for continuous monitoring to protect workers from the threat of silicosis, regardless of their occupational environment.

Our real-time RCS monitor, AIR XS provides a real-time solution to this threat. Workers are not only alarmed and alerted when silica levels exceed legislative limits but can work to best practices by implementing AIR XS with the Hierarchy of Controls, supporting proactive measures to eliminate or minimise exposure to RCS. This move to real-time monitoring as a solution to the threat of silicosis has also been noticed by governing bodies, like the All-Party Parliamentary Group on Respiratory Health.

To learn more about how this real-time solution not only enhances worker safety but also streamlines business operations, click the link below to read the case study in full.

New test findings released, confirm the efficacy of a world-first real-time monitor for silica dust, which represents a revolution in the protection for workers exposed to respirable crystalline silica (RCS) dust.

As a leading workplace safety technology company, we have developed the AIR XS Silica Monitor, designed to protect workers against lung diseases such as silicosis by providing real-time readings of levels of crystalline silica in the air.

We have recently commissioned a leading occupational hygiene and laboratory testing organisation to conduct independent testing of the AIR XS. The results show the AIR XS repeatedly provided consistent, accurate, real-time data throughout an eight-hour testing period.

The testing demonstrates that AIR XS can improve worker safety by providing instant information to businesses and workers exposed to RCS, instead of having to wait up to four weeks to know their level of exposure to this killer dust, which is the current industry standard.

While the Australian Government recently implemented a ban on engineered stone, commencing 1 July 2024, the process most synonymous with creating silica dust, Group CEO Glyn Pierce-Jones said this ban alone would not solve the current health crisis caused by RCS.

“Silica dust is found in most building materials, so while banning engineered stone is a positive step, it’s not a holistic solution. The real issue facing the industry is the current archaic methods of testing for silica dust and the delay it causes in creating the safest possible workplace.”

The AIR XS is already being used in Australia to monitor RCS levels in many industrial locations.

Silica occurs naturally in soil, sand and granite; however, it is almost harmless in that state. Once those materials have been disturbed through construction or mining, silica dust is generated and can be inhaled into the lungs. This dust can cause silicosis, and other types of lung diseases and cancer, which are often irreversible and progressive.

Recent research from The Lung Foundation showed an estimated 600,000 Australian workers and between 40-50 million workers worldwide are exposed to silica dust across a wide range of industries including quarrying, construction, tunnelling, mining and many manufacturing processes.

The current approach to test for RCS is gravimetric sampling, the process requires collection, processing, and laboratory analysis of the sample, which is both time-consuming and costly for businesses. Direct-reading instruments offer businesses the ability to monitor employee safety on sites in real-time, eliminating the delays of weeks typically associated with potential RCS exposure.

Mr Pierce-Jones emphasised the urgent need for enhanced safety measures for anyone who may be in contact with silica.

“The current testing methodology for RCS only allows users to take an average reading over an eight-hour period and typically takes up to four weeks to produce a result,” Mr Pierce-Jones said.

“Our AIR XS Silica Monitor was designed to provide an accurate reading with immediate results, letting workers know when their health is in danger and allowing employers to respond in the most efficient manner.”

“These latest test results are another indicator of what we already knew at Trolex – that the AIR XS could be part of a desperately needed solution to an urgent health crisis.”

It’s estimated that over 40 million people worldwide are exposed to silica dust in the workplace. Respirable crystalline silica (RCS) contributes to one of the leading causes of death in the workplace, alongside other lung related illnesses. Due to this some of the industry’s most influential countries worldwide are making significant changes to regulations regarding silica exposure in the workplace.

In December 2023, Australia became the first country in the world to ban engineered stone due to rising cases of silicosis. From 1st July 2024, all use of engineered stone in Australia will be prohibited to protect workers from exposure to RCS in the workplace. Engineered stone is a manufactured material made from combining quartz or granite aggregates with resins and pigment and is a common material used in stone bench tops, often found in kitchens and bathrooms. It’s production often results in airborne RCS, leading to significant health risks to those working with it.

With reports that over half a million Australians are exposed to fine silica dust through stonemasonry and construction, figures suggest 103,000 of these workers are likely to be diagnosed with silicosis. The production and manufacturing of stone bench tops is a significant contributor to these statistics. The ban on engineered stone across the entirety of Australia is a step in the right direction to reduce the number of workers exposed to RCS and silicosis diagnosis in the future.

This ruling in Australia looks to have a set a precedent in influencing other countries to do the same. In May 2024, the first cases of silicosis linked to artificial stone countertops in the UK were reported, leading to calls for the material to be banned.

An estimated 600,000 workers are exposed to silica in the UK each year, and in Europe as a whole, 81% of those exposed are employed in construction or in manufacturing products used in the industry. After Australia became the first country worldwide to ban engineered stone in December 2023, UK kitchen company Herringbone announced they would also ban the sale of high-silica quartz worktop due to the risks posed to stonemasons.

Since speaking with their stonemasons about the risk of high quartz in engineered stone, Herringbone made the decision to become the first company in the UK to phase out the sale and production of engineered stone, as well as creating a petition to have the product completely banned in the UK, like in Australia.

In the US, the Biden administration has agreed to limit workers exposure to silica dust in mining, particularly when drilling for coal, ore and completing other mining operations. In April 2024, a ruling was announced to reduce the allowable silica dust levels in mining operations to 50 micrograms per cubic meter, with an action level at 25 micrograms, for an eight-hour workday.

The ruling will also update any respiratory protection standards for mining workers and in addition to silica dust, will also apply to diesel particulate matter and asbestos. The hope is that this will begin to reduce an estimated 1,067 deaths and 3,746 silica related illnesses in mining industries in the US and begin to make mining safer from the risk of RCS for the 55,000 American coal miners across the nation. The rule will come into action one year after its publication in April 2024.

With significant action being taken across major industries worldwide as of mid-2024 and onwards, protection for workers against respirable crystalline silica is becoming more of a high priority in workplaces. With banning of products known to produce dangerous levels of RCS, and with rule changes to limit exposure, workers short- and long-term lung health is becoming better protected than ever.

We’re excited to bring to the market our XD1+ Personal Dust Monitor as a connected dust monitor with the Reactec Ecosystem.

The Reactec Ecosystem for workplace exposure to hazards includes an IoT gateway, Reactec’s workplace wearable RASOR for secure data transmission, an RFID identity card to personalise the collected dust data and the cloud-based Reactec Analytics software for informative and automatic data dissemination.

RASOR is a communications gateway with integrated SIM and GPS technology to gather data seamlessly from the XD1+ and present it live, personalised and position tracked data to remote line managers via a browser.

Our XD1+ Personal Dust Monitor can be easily connected with RASOR in two different modes for both single worker use and for pairing a number of XD1+ devices to a RASOR connected in hub mode, allowing for flexibility when working, but still providing vital information of worker exposure which can be analysed and interrogated on Reactec’s Analytics platform.

By leveraging revolutionary real-time personal monitoring technology with location tracking, automatic data collection and powerful data analytics, employers can now control their worker’s exposure to harmful respirable dust like never before and reduce these occupational diseases thanks to connected XD1+ and Reactec Ecosystem.

Check our guide for details on the key modes of pairing XD1+ with the Reactec Ecosystem, a run-through of how to connect your XD1+ in these different modes and the benefits of each type of connectivity.

A manufacturer of prestigious natural stone, Burlington Stone have quarried for over 200 years across the English Lake District, extracting and crafting a diverse range of signature British natural slate and stone products.

Individuals across their workforce are often exposed to hazardous substances, most notably airborne dust, including silica dust. Burlington Stone trialed two XD1+ devices on their site for a month to see how real-time, personal dust monitoring would improve their safety processes.

After the trial, we spoke to Health and Safety Manager, Peter Walker, about the success of the trial and some of the major benefits which Burlington Stone’s workforce found deploying XD1+ Personal Dust Monitor units in their day-to-day processes.

With over 45 years of experience in the field of tunnelling, our partners, Timeco, are experts when it comes to tunnel boring machine (TBM), piling and foundation works, and other important activities involved in tunnelling. And when it comes to environmental monitoring for harsh tunnelling conditions, their partnership with Trolex has provided solutions to the entire tunnelling industry.

“We are satisfied with the 20+ years of cooperation with Trolex, as our official partner, because of the mutual trust in the innovative organisation and the reliability, user friendly

and durability of its products and solutions.” said Timeco, about the collaboration with Trolex to provide solutions to hazardous conditions in the tunnelling industry.

Trolex’s product range, provided to the tunnelling market in Europe by Timeco, includes a full range of dust monitoring technology, including AIR XD Dust Monitor and AIR XS Silica Monitor, as well as gas detection equipment, such as TX9165 Sentro 8 and TX6351-2 Sentro 1, detecting for a full range of hazardous gases.