With an estimated 1 million people dying globally from the inhalation of dust in occupational environments every year, now is the time to protect your workers. Real-time dust and silica monitoring provides instant alarms and alerts for all workers at risk of dangerous dusk regardless of their application, processes or industry.

We’re continuously innovating real-time dust monitoring technology to give you access to the information to effect change and keep your workers safe from hazardous respirable dusts. With a range of dust and silica monitoring options, we’re here to help you protect your workers.

Whether that’s heavy-duty area monitoring for high dust loading environments, personal dust monitoring for individual monitoring needs, or silica monitoring for working environments with high respirable crystalline silica (RCS) content, such as stonemasonry, tunnelling or quarrying.

Real-time monitoring offers solutions to us in our everyday lives. Whether it’s the real-time alerts that tells you that you’re at risk or in danger, or the subsequent data which provides you accurate information on what you’re monitoring, real-time monitoring has become an essential part of our lives.

But what about real-time monitoring when it comes to enhancing the workforce? You’d rely on real-time monitoring and alarms to tell you there’s a fire in your home, so why wouldn’t you rely on real-time monitoring to tell you if you were a risk as serious to your health at work? You’d rely on real-time data to tell you if you needed to track nutrition or health trends, so why wouldn’t you rely on essential data in real-time in the workplace?

Whether it’s for the health and safety of you and your colleagues, to better understand the processes and efficiency of the business, or just to help aid decisions, real-time monitoring can provide valuable data to workforces across a whole range of industries. Whether you are monitoring for hazardous substances like dust or silica, or monitoring for HAV, sound levels or proximity measures, real-time monitoring can enhance your workforce.

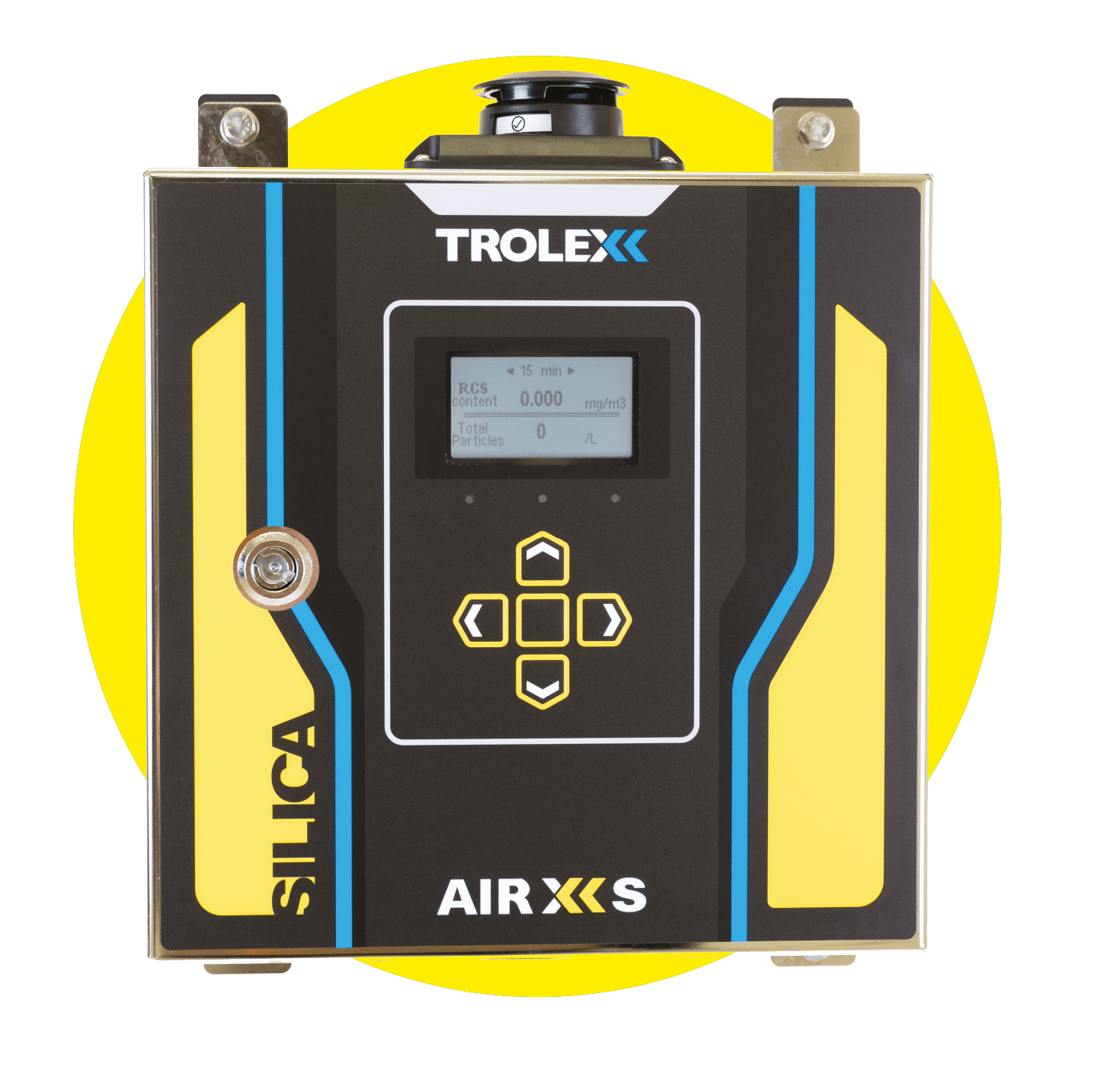

The AIR XS Silica Monitor leverages cutting-edge Optical Refraction Technology (ORT) to enhance workplace safety by providing real-time monitoring of respirable crystalline silica (RCS). Unlike traditional particle monitors, AIR XS distinguishes and measures RCS content, enabling immediate detection and response to harmful silica dust levels. This technology is crucial in combating occupational lung diseases such as silicosis, which affects millions of workers globally.

Current monitoring methods, like gravimetric sampling, are time-consuming and often deliver results too late to prevent exposure. In contrast, real-time silica monitoring offers immediate data, significantly reducing the risk of occupational silicosis by enabling prompt action to mitigate hazardous conditions. The importance of such real-time data is highlighted by cases like Joanna McNeill’s, who developed silicosis at the age of just 36. Her story, like many others underscores the necessity for continuous monitoring to protect workers from the threat of silicosis, regardless of their occupational environment.

Our real-time RCS monitor, AIR XS provides a real-time solution to this threat. Workers are not only alarmed and alerted when silica levels exceed legislative limits but can work to best practices by implementing AIR XS with the Hierarchy of Controls, supporting proactive measures to eliminate or minimise exposure to RCS. This move to real-time monitoring as a solution to the threat of silicosis has also been noticed by governing bodies, like the All-Party Parliamentary Group on Respiratory Health.

To learn more about how this real-time solution not only enhances worker safety but also streamlines business operations, click the link below to read the case study in full.

New test findings released, confirm the efficacy of a world-first real-time monitor for silica dust, which represents a revolution in the protection for workers exposed to respirable crystalline silica (RCS) dust.

As a leading workplace safety technology company, we have developed the AIR XS Silica Monitor, designed to protect workers against lung diseases such as silicosis by providing real-time readings of levels of crystalline silica in the air.

We have recently commissioned a leading occupational hygiene and laboratory testing organisation to conduct independent testing of the AIR XS. The results show the AIR XS repeatedly provided consistent, accurate, real-time data throughout an eight-hour testing period.

The testing demonstrates that AIR XS can improve worker safety by providing instant information to businesses and workers exposed to RCS, instead of having to wait up to four weeks to know their level of exposure to this killer dust, which is the current industry standard.

While the Australian Government recently implemented a ban on engineered stone, commencing 1 July 2024, the process most synonymous with creating silica dust, Group CEO Glyn Pierce-Jones said this ban alone would not solve the current health crisis caused by RCS.

“Silica dust is found in most building materials, so while banning engineered stone is a positive step, it’s not a holistic solution. The real issue facing the industry is the current archaic methods of testing for silica dust and the delay it causes in creating the safest possible workplace.”

The AIR XS is already being used in Australia to monitor RCS levels in many industrial locations.

Silica occurs naturally in soil, sand and granite; however, it is almost harmless in that state. Once those materials have been disturbed through construction or mining, silica dust is generated and can be inhaled into the lungs. This dust can cause silicosis, and other types of lung diseases and cancer, which are often irreversible and progressive.

Recent research from The Lung Foundation showed an estimated 600,000 Australian workers and between 40-50 million workers worldwide are exposed to silica dust across a wide range of industries including quarrying, construction, tunnelling, mining and many manufacturing processes.

The current approach to test for RCS is gravimetric sampling, the process requires collection, processing, and laboratory analysis of the sample, which is both time-consuming and costly for businesses. Direct-reading instruments offer businesses the ability to monitor employee safety on sites in real-time, eliminating the delays of weeks typically associated with potential RCS exposure.

Mr Pierce-Jones emphasised the urgent need for enhanced safety measures for anyone who may be in contact with silica.

“The current testing methodology for RCS only allows users to take an average reading over an eight-hour period and typically takes up to four weeks to produce a result,” Mr Pierce-Jones said.

“Our AIR XS Silica Monitor was designed to provide an accurate reading with immediate results, letting workers know when their health is in danger and allowing employers to respond in the most efficient manner.”

“These latest test results are another indicator of what we already knew at Trolex – that the AIR XS could be part of a desperately needed solution to an urgent health crisis.”

It’s estimated that over 40 million people worldwide are exposed to silica dust in the workplace. Respirable crystalline silica (RCS) contributes to one of the leading causes of death in the workplace, alongside other lung related illnesses. Due to this some of the industry’s most influential countries worldwide are making significant changes to regulations regarding silica exposure in the workplace.

In December 2023, Australia became the first country in the world to ban engineered stone due to rising cases of silicosis. From 1st July 2024, all use of engineered stone in Australia will be prohibited to protect workers from exposure to RCS in the workplace. Engineered stone is a manufactured material made from combining quartz or granite aggregates with resins and pigment and is a common material used in stone bench tops, often found in kitchens and bathrooms. It’s production often results in airborne RCS, leading to significant health risks to those working with it.

With reports that over half a million Australians are exposed to fine silica dust through stonemasonry and construction, figures suggest 103,000 of these workers are likely to be diagnosed with silicosis. The production and manufacturing of stone bench tops is a significant contributor to these statistics. The ban on engineered stone across the entirety of Australia is a step in the right direction to reduce the number of workers exposed to RCS and silicosis diagnosis in the future.

This ruling in Australia looks to have a set a precedent in influencing other countries to do the same. In May 2024, the first cases of silicosis linked to artificial stone countertops in the UK were reported, leading to calls for the material to be banned.

An estimated 600,000 workers are exposed to silica in the UK each year, and in Europe as a whole, 81% of those exposed are employed in construction or in manufacturing products used in the industry. After Australia became the first country worldwide to ban engineered stone in December 2023, UK kitchen company Herringbone announced they would also ban the sale of high-silica quartz worktop due to the risks posed to stonemasons.

Since speaking with their stonemasons about the risk of high quartz in engineered stone, Herringbone made the decision to become the first company in the UK to phase out the sale and production of engineered stone, as well as creating a petition to have the product completely banned in the UK, like in Australia.

In the US, the Biden administration has agreed to limit workers exposure to silica dust in mining, particularly when drilling for coal, ore and completing other mining operations. In April 2024, a ruling was announced to reduce the allowable silica dust levels in mining operations to 50 micrograms per cubic meter, with an action level at 25 micrograms, for an eight-hour workday.

The ruling will also update any respiratory protection standards for mining workers and in addition to silica dust, will also apply to diesel particulate matter and asbestos. The hope is that this will begin to reduce an estimated 1,067 deaths and 3,746 silica related illnesses in mining industries in the US and begin to make mining safer from the risk of RCS for the 55,000 American coal miners across the nation. The rule will come into action one year after its publication in April 2024.

With significant action being taken across major industries worldwide as of mid-2024 and onwards, protection for workers against respirable crystalline silica is becoming more of a high priority in workplaces. With banning of products known to produce dangerous levels of RCS, and with rule changes to limit exposure, workers short- and long-term lung health is becoming better protected than ever.

With over 45 years of experience in the field of tunnelling, our partners, Timeco, are experts when it comes to tunnel boring machine (TBM), piling and foundation works, and other important activities involved in tunnelling. And when it comes to environmental monitoring for harsh tunnelling conditions, their partnership with Trolex has provided solutions to the entire tunnelling industry.

“We are satisfied with the 20+ years of cooperation with Trolex, as our official partner, because of the mutual trust in the innovative organisation and the reliability, user friendly

and durability of its products and solutions.” said Timeco, about the collaboration with Trolex to provide solutions to hazardous conditions in the tunnelling industry.

Trolex’s product range, provided to the tunnelling market in Europe by Timeco, includes a full range of dust monitoring technology, including AIR XD Dust Monitor and AIR XS Silica Monitor, as well as gas detection equipment, such as TX9165 Sentro 8 and TX6351-2 Sentro 1, detecting for a full range of hazardous gases.

Our AIR XS Silica Monitor, an innovative real-time respirable silica (RCS) monitoring device, has been deployed at a major railway operations project to monitor the levels of RCS which workers may be exposed to.

The Central Rail Systems Alliance (CRSA), an alliance between Network Rail, Balfour Beatty, AtkinsRéalis and TSO have been using an AIR XS unit to monitor the levels of RCS released when damaged rail tracks are replaced; when rail track is damaged or needs replacing, the ballast surrounding the track is disturbed and can release RCS. The AIR XS unit was supplied by our UK partners Sunbelt UK & Ireland.

The challenge faced by CRSA was to measure the level of RCS and accompanying dust being released into the atmosphere during the unearthing process of 425m rail and ascertain the level of risk associated for those working in the immediate and surrounding environments. The AIR XS unit was manoeuvred around the site in-line with project progress, so that working scenarios can be accurately represented in the data set.

Upon conclusion of the project, Madeline Dunn, the Health and Safety Advisor for CRSA praised the monitoring and recording capabilities of the AIR XS, saying “We have completed trials prior, however this is the only unit where it is measuring silica and not just general dust levels. We gained the knowledge that the exposure levels were actually higher than we anticipated with even low-level ballast disturbance.”

Thanks to the team at Sunbelt Rentals UK & Ireland for the in-depth case study which you can read in full here.

Launched in 2022, the AIR XS Silica Monitor isn’t like other silica monitors on the market. If you’ve been in the Health and Safety space, it’s likely you’ll know about Optical Particle Counter (OPC), also known as “light-scattering”; but our patented AIR XS isn’t just another OPC.

Unlike traditional Optical Particle Counters (OPCs) that rely on light scattering and interruptions to deduce particle size and quantity, the patented Optical Refraction Technology (ORT) used in the AIR XS shines a laser through each particle, capturing its refraction on multiple sensors.

In our blog below, we reference Pink Floyd’s 1973 album Dark Side of the Moon to explain one way to how ORT works. It’s not exact by any means but the refraction of the light coming out of the prism shows an example of how light refracts, similar to a crystalline particle.

Silicosis is now the most common occupational lung disease in the world, with silica dust described as ‘the new asbestos’ due to the extreme threat it poses to human health.

Silica dust (respirable crystalline silica (RCS)) is extremely harmful to human health due to its physical and biological properties.

It affects around 50,000,000 workers in a wide variety of industries all around the world and prolonged exposure leads to silicosis and a wide range of other diseases, most of which are untreatable and often lead to long-term disability and/or death.

The potential for harm is even worse than that when you consider that asbestos is one of many different silica compounds and silica is the most proliferate mineral on earth; present in bricks, sand, stone, concrete, glass, cement and many other construction and building materials. 99% of deaths in occupational settings, are caused by the inhalation of dangerous particulates, with the other significant factor in this statistic being the extreme difficulty in monitoring in real-time for these killer particulates

It has never been possible to reliably detect and distinguish silica dust in real time in the real-world settings in which workers are exposed to it – until now.

The white paper looks at the background of silica exposure, the current methodologies employed to monitor it and the new technological advancement that has led to the development of a field-ready product for the first time in history.

Legislated limits of exposure have been tightening up in most major economies as the harm being caused becomes known, but reductions in limits and the implementation of these limits have been hampered by the lack of real-time accurate and reliable monitoring capability.

This technology has the potential to change the way industry, governments, businesses and workers themselves respond to the threat of RCS exposure in the workplace, and as such, it can be the beginning of the end for occupational silicosis. Not only does it improve health and safety outcomes for frontline workers, but it also reduces costs for businesses whilst giving them back control over their working environment.

Perhaps most importantly of all, it gives legislative bodies the tool they need to create and implement workplace exposure limits (WELs) that genuinely protect workers from harm, at a cost industry can bear, ending decades of debate over what the limits should be and how practicable it is for industry to meet them.

In 2020, the All-Party Parliamentary Group for Respiratory Health (APPG) issued the report “Silica, the next asbestos?”, which examined the disproportionate effect of silica dust to construction workers’ lives.

Since the publication of that report, the APPG were contacted by a number of experts on the subject matter, who highlighted the advances in risk reduction and the particularly promising rise of real-time dust and silica monitoring technology.

“Trolex believe that the most obvious and immediate benefit of real-time monitoring is in improving safety for those potentially exposed to silica in the workplace.”

The new, revised report, titled “Improving Silicosis Outcomes in the UK” also explored these new silicosis prevention strategies, including some input from Trolex on the subject matter. From this, the APPG raised several clinical and regulatory recommendations to protect workers from the dangers of occupational silicosis going forward.

“We recommend that the Health and Safety Executive (HSE) assesses and determines the data and technology needed to allow the UK to reduce the WEL for work with silica to 0.05mg/m3.”

The recommendations from the APPG’s report indicate a number of changes need to be made in order to improve safety across all UK industries which use silica. These recommendations focus on both ways to prevent exposure to dangerous respirable crystalline silica (RCS) in the workplace, including improvements in education, real-time monitoring and reducing exposure limits, as well as improving health and support for those who currently suffer with silicosis.

“We recommend that the HSE actively considers and consults with industry on the positions of real-time monitoring to complement the hierarchy of controls.”