With an estimated 1 million people dying globally from the inhalation of dust in occupational environments every year, now is the time to protect your workers. Real-time dust and silica monitoring provides instant alarms and alerts for all workers at risk of dangerous dusk regardless of their application, processes or industry.

We’re continuously innovating real-time dust monitoring technology to give you access to the information to effect change and keep your workers safe from hazardous respirable dusts. With a range of dust and silica monitoring options, we’re here to help you protect your workers.

Whether that’s heavy-duty area monitoring for high dust loading environments, personal dust monitoring for individual monitoring needs, or silica monitoring for working environments with high respirable crystalline silica (RCS) content, such as stonemasonry, tunnelling or quarrying.

Real-time monitoring offers solutions to us in our everyday lives. Whether it’s the real-time alerts that tells you that you’re at risk or in danger, or the subsequent data which provides you accurate information on what you’re monitoring, real-time monitoring has become an essential part of our lives.

But what about real-time monitoring when it comes to enhancing the workforce? You’d rely on real-time monitoring and alarms to tell you there’s a fire in your home, so why wouldn’t you rely on real-time monitoring to tell you if you were a risk as serious to your health at work? You’d rely on real-time data to tell you if you needed to track nutrition or health trends, so why wouldn’t you rely on essential data in real-time in the workplace?

Whether it’s for the health and safety of you and your colleagues, to better understand the processes and efficiency of the business, or just to help aid decisions, real-time monitoring can provide valuable data to workforces across a whole range of industries. Whether you are monitoring for hazardous substances like dust or silica, or monitoring for HAV, sound levels or proximity measures, real-time monitoring can enhance your workforce.

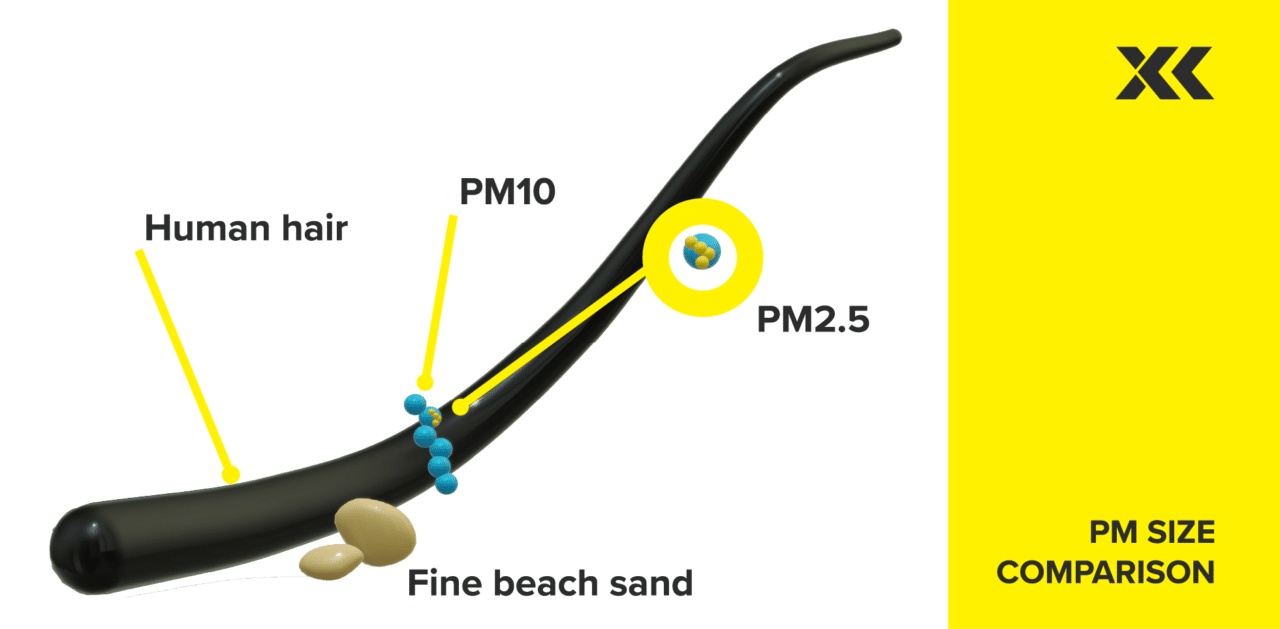

‘PM’ or particulate matter, also known as particle pollution is the term for a mixture of solid particles and liquid droplets found in the air.

It’s estimated that air pollution is linked to 43,000 deaths per year in the UK. Worldwide, at least 7 million people die each year from exposure to air pollution, with 91% of the worldwide population living in locations where the air quality exceeded the World Health Organisations (WHO) air pollution guidelines.

These guidelines state that that annual average concentrations of PM2.5 should not exceed 5 µg/m3 and PM10 should not exceed 15 µg/m3 (both for 24-hour periods). According to the WHO, ‘fine particulate matter at PM2.5 can penetrate through the lungs and further enter the body through the blood stream, affecting all major organs’. Exposure to dust at PM2.5 can cause serious disease to the respiratory system, such as lung cancer and COPD, and also can effect cardiovascular diseases, such as a stroke.

The image below demonstrates PM2.5 and PM10 size in comparison to a single human hair and a grain of sand.

The Department for Environment Food & Rural Affairs (DEFRA), the UK government ministerial department for environment protection, have also highlighted the severity of exposure to air pollution. This growing concern for the UK government estimated in 2010 that the cost of health impacts of air pollution was likely to exceed estimates of £8bn to £20bn.

Although between 2005 and 2022, the UK’s PM2.5 emissions decreased by 41%, emission levels have been relatively steady with small annual fluctuations in the last decade. Industrial combustion is a major source of PM emissions, as well as emissions from industrial production also playing a major part, which can be linked to heavy-dust industry where hazardous particulates can become airborne. Despite some reductions in PM emissions, the threat still very much remains.

A solution to this is real-time dust monitoring. Real-time particulate monitoring allows people in heavy dust loading environments, including industrial applications, to not only understand, but alert them instantaneously when they are exposed to dangerous levels of air pollution. For example, our AIR XD Dust Monitor can alert people in real-time when legislative levels of µg/m3 are breached, over a time-weighted average (TWA) 8-hour period, for both PM2.5 and PM10.

This technology not only offers a simple solution to individuals at high risk of exposure to air pollution by providing instant alerts, but also can help to prevent exposure in the future, as at-risk individuals can learn exactly when and where exposure to air pollution is highest and will likely occur. Thanks to real-time monitoring, both in the UK and Worldwide, we can reduce exposure to air pollution.

With over 45 years of experience in the field of tunnelling, our partners, Timeco, are experts when it comes to tunnel boring machine (TBM), piling and foundation works, and other important activities involved in tunnelling. And when it comes to environmental monitoring for harsh tunnelling conditions, their partnership with Trolex has provided solutions to the entire tunnelling industry.

“We are satisfied with the 20+ years of cooperation with Trolex, as our official partner, because of the mutual trust in the innovative organisation and the reliability, user friendly

and durability of its products and solutions.” said Timeco, about the collaboration with Trolex to provide solutions to hazardous conditions in the tunnelling industry.

Trolex’s product range, provided to the tunnelling market in Europe by Timeco, includes a full range of dust monitoring technology, including AIR XD Dust Monitor and AIR XS Silica Monitor, as well as gas detection equipment, such as TX9165 Sentro 8 and TX6351-2 Sentro 1, detecting for a full range of hazardous gases.

In 2020, the All-Party Parliamentary Group for Respiratory Health (APPG) issued the report “Silica, the next asbestos?”, which examined the disproportionate effect of silica dust to construction workers’ lives.

Since the publication of that report, the APPG were contacted by a number of experts on the subject matter, who highlighted the advances in risk reduction and the particularly promising rise of real-time dust and silica monitoring technology.

“Trolex believe that the most obvious and immediate benefit of real-time monitoring is in improving safety for those potentially exposed to silica in the workplace.”

The new, revised report, titled “Improving Silicosis Outcomes in the UK” also explored these new silicosis prevention strategies, including some input from Trolex on the subject matter. From this, the APPG raised several clinical and regulatory recommendations to protect workers from the dangers of occupational silicosis going forward.

“We recommend that the Health and Safety Executive (HSE) assesses and determines the data and technology needed to allow the UK to reduce the WEL for work with silica to 0.05mg/m3.”

The recommendations from the APPG’s report indicate a number of changes need to be made in order to improve safety across all UK industries which use silica. These recommendations focus on both ways to prevent exposure to dangerous respirable crystalline silica (RCS) in the workplace, including improvements in education, real-time monitoring and reducing exposure limits, as well as improving health and support for those who currently suffer with silicosis.

“We recommend that the HSE actively considers and consults with industry on the positions of real-time monitoring to complement the hierarchy of controls.”

You may have seen The All Party Parliamentary Group (APPG) for Respiratory Health report ‘Silica – the next asbestos’ released in March 2020?

In it, it states:

“Construction workers are still 100 times more likely to die from a preventable occupational disease than from an accident. We also know that approximately 12,000 deaths in the industry each year are linked to exposure to dust and chemicals.”

“Figures from IOSH show that roughly half a million people are exposed to RCS at work in the UK. They estimate that in Europe as a whole, 81% of these are employed in construction or in manufacturing products used in that industry.”

Experts at Trolex brought our new technology to the APPG’s attention and explained our nine-year silica detection R&D project that resulted in development of the new real-time silica monitor – work that we’d kept closely under wraps until mid 2021.

The original report refers to Workplace Exposure Limits (WELs) of dust. It says:

“Dust monitoring is vital. Technology advances mean that new methods of real-time exposure level monitoring are now possible. Knowing what the actual exposure levels are is important as exposure will depend on the actual task (e.g. cutting concrete is higher risk than breaking concrete, and the actual exposures depend on the concrete mixture).

“The new Code of Practice for Tunnelling […] that requires the use of new technology which is just becoming available and gives an instantaneous measurement.”

The instantaneous measurement the report refers to is the measurement of a variety of dust and particulates (something we already do with our AIR XD Dust Monitor and XD One Portable Dust Monitor, XD1+ Personal Dust Monitor products) – not specifically silica. Silica always being too difficult to uniquely identify.

Until now.

Our new silica-specific monitoring technology is a game changer.

By working with the authors of the APPG to share the features, benefits and thinking behind the new real-time silica monitoring technology they’ve been able to update the report with new advice on how to best protect workers from the dangers of respirable crystalline silica (RCS).

Protecting the health and safety of the people who work for you is the ethical thing to do. It also makes good business sense as your people are your greatest asset.

But even if you aren’t driven by a moral or financial imperative, governments around the world are toughening up on the legislation that protects workers, so it’s not something any business can afford to ignore.

While some threats are obvious, others are invisible and incredibly hard to accurately detect, such as the deadly silica dust that are the by-product of many industries and manufacturing processes.

Silica dust is linked with severe health problems. It has been dubbed the ‘new asbestos’ and has already been the subject of litigation. Yet it’s something that has historically been impossible to monitor in real time.

Our Construction Industry Health and Safety Survey Winter 2021 shows that employers are concerned about safety, with nine out of 10 respondents recognising that worker safety is important or very important.

But it also revealed that on the ground it can be hard to meet the health and safety challenge, particularly when it comes to dust monitoring, which for a fifth of respondents accounted for half of their safety budget.

This in-depth report looks at how real-time, wearable dust monitoring technology can help to solve the issues from the findings of the Construction Industry Health and Safety Survey Winter 2021.

The findings ultimately mean that it’s clear we need a new approach to dust monitoring. One that looks to the future and is inspired by the intelligent tech revolutionising every other aspect of our lives.

It’s time to act now to tackle danger of hazardous dusts, like silica dust, by investing in smarter solutions to protect the air we breathe, with real-time dust monitoring.

Silica dust is the new asbestos.

But what if it’s not? What if there’s really nothing new about silica dust in relation to asbestos?

The link between the two is even closer than you may think…

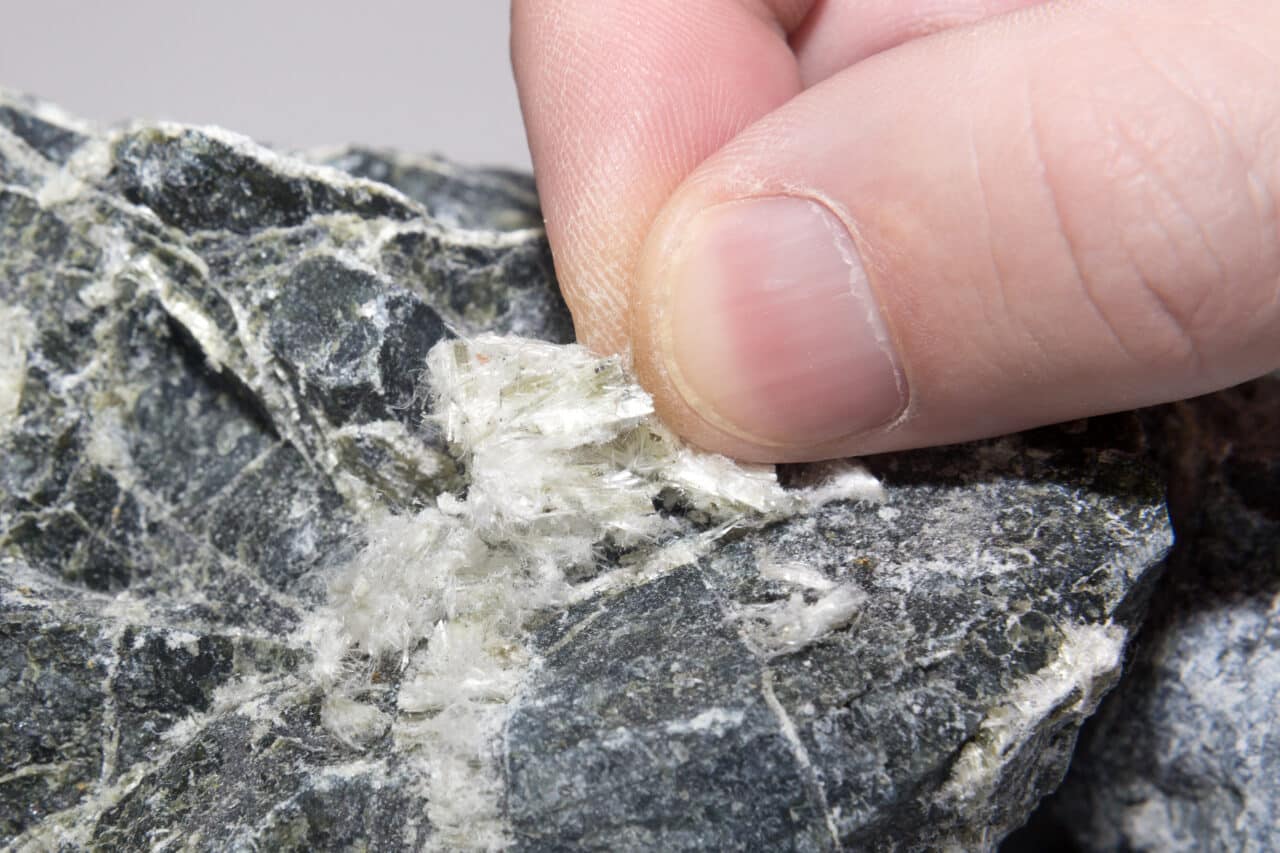

Most people know asbestos as the dangerous insulator used in construction, responsible for over 5,000 related disease-deaths per year, typically lung cancer and asbestosis.

However, in its natural form, asbestos is a naturally occurring fibrous silicate mineral.

Put simply, silicate minerals make up asbestos fibres.

Asbestos is actually just one of the many different forms of silicate materials, in the same way that silica dust is.

The similarities between silica dust and asbestos are much closer than people are aware of.

There is a different attitude towards asbestos compared to silica dust.

The dangers of exposure to asbestos are well documented.

Exposure to asbestos can cause serious lung conditions, including asbestosis and mesothelioma. It is the number 1 cause of recorded work-related deaths in the world.

Most people in the UK are aware of its dangers, particularly as asbestos was banned in 1999 for construction work in the UK.

Yet despite all of this, very few people are aware of how dangerous exposure to silica dust is, despite the fact that asbestos fibres are made up of silicate materials, in the same way silica is.

There are many more dangers relating to silica dust than people may be aware of.

Imagine you are working on refurbishing your bathroom and from the grinding of the ceramic sink and a load of dust becomes airborne.

If you were told that this airborne dust which you were inevitably inhaling was asbestos, you’d probably run a mile, right?

And who could blame you? A dust which is responsible for approximately 90,000 asbestos-related diseases per year. You’d want to get as far away from it as possible.

Well, it’s likely that that dust in your bathroom would in fact be silica dust.

A dust which is made up of silicate materials in the same way asbestos fibres are. A respirable dust which is just as lethal, if not more lethal, in comparison to asbestos dust.

But because it isn’t known to people as being the same as asbestos, the dangers seem to be less of a concern to people.

It’s time to get real and become aware of just how dangerous silica dust is.

It is reported that, in crystalline form, respirable crystalline silica (RCS) is responsible for the death of 600 people per year in Great Britain with 450 of those to workers in construction industry. What’s more, an estimated 50,000 workers are exposed to silica dust globally.

The importance of the dangers of silica dust must be realised, especially with what is known about how dangerous asbestos is.

Asbestos is just as lethal as silica dust. The dangers are the same, yet we cannot afford for the results of exposure to silica dust to be the same as what occurred with asbestos.

Silica could be as lethal as asbestos, if not more so, with equally serious consequences.

Being aware of the issue is the start, action must be taken to protect workers from this dangerous dust.

We cannot afford to let history repeat itself.

Have you heard of the ‘psychological contract’? It’s the unwritten understanding of the interaction between you, your workplace environment and your colleagues.

We all have a psychological contract with our employers, whether we know it or not.

As well as considering the physical aspects of your work environment, your psychological contract includes things like the quality of relationships you have with the people you work with, whether you feel properly listened to and understood and know what’s expected of you in your role.

An important part of that contract is ‘psychological safety’. How safe or unsafe your psychological contract leaves you feeling at work.

A term coined in 1999 by organisational behavioural scientist, Amy Edmondson, ‘psychological safety’ includes things like trust in your colleagues, your perception of physical threat in your working environment and how you feel about the training and support you get to do your job.

Unsurprisingly, the safer people feel at work, both physically and emotionally, the more productive they are.

By the same token, if people feel unsafe, then not only are they less productive, but the time the trouble and expense of having to replace people unhappy in their jobs is huge.

Employee benefits provider Perkbox estimates that ‘disengaged employees are costing the UK economy £340 billion every year in lost training and recruitment costs, sick days, productivity, creativity and innovation.’

So how can you make sure that people in your organisation feel psychologically safe?

The first important step in creating a psychologically safe workplace is to make it as physically safe as possible.

Speaking with Trolex, Occupational Psychologist Catherine Dobson told us, “If an environment is not physically safe, if it’s too hot, too cold, or if it feels too dangerous people feel stressed. We must ask ourselves how do we get the right environment for people with the right kind of training, the right kind of cooperation to make it healthier?

Which is what contributes to making our range of dust monitors, such an important development. These include the AIR XD Dust Monitor, the XD ONE Portable Dust Monitor – our wearable dust monitoring technology, and our AIR XS Silica Monitor for real-time silica dust monitoring.

Not simply because it protects workers from the physical dangers of inhaling lethal respirable dusts, but because armed with the knowledge that they are working safely, people feel psychologically safer too.

Catherine explains how: “In relation to silica and dust monitoring. Because the AIR XS Silica Monitor is new, there’s scope for demonstrating that it works. And people can see that.

Also, because all these dust monitors work in real time, it gives people the trust that an intervention will take place should they be in danger. They can trust in the environment being safe.”

A very good thing for workers on both a physical and emotional level.

And great news, too, for the mining, tunnelling, quarrying, manufacturing and construction companies invested in fulfilling their side of the psychological contract with advanced dust monitoring.

Businesses can then reap the rewards of improved production and better worker retention, so everybody wins.

It’s the twenty-first century, and we are in “the age of data”. Everything is data-driven from what we do and use. Even the devices we carry around with us all day, like our mobile phones, and most recently, even smart watches are mainly data tracking devices.

And whilst many are sceptical of how the data is used, realistically everyone is positively affected by modern data collection. Even if we don’t realise it, data today is allowing us to make educated changes to our lifestyle, finances, social lives and health.

It seems odd that a widely available resource such as data is taken for granted everyday, and isn’t used effectively to do the really important things more regularly – especially when it comes to saving lives and preventing life threatening illnesses.

Sadly, the global annual number of people dying from occupational respiratory illnesses is estimated at over 500,000. The critical question remains: are we using the data at our disposal to positively impact workplace health and safety? Probably not…

Firstly, we need to understand that data is critical, and a lack of its use is a problem. Real-time dust monitoring has long since been an expensive, complicated “black art” unavailable to the masses. Whilst monitoring isn’t a solution in itself, it’s pivotal to making the right decisions to ultimately save lives and understand where the risk really lies.

Gravimetric or “dust deposit” gauges have long been an industry standard, and a legislative medium for measuring harmful dust exposure; but they only give ‘one side of the story’ and even then a partial story at best. When it comes to saving lives, time is of the essence. Even more so early detection and real-time alarming typically results in prompt action.

This gravimetric data is not to be dismissed and is important, but let’s face it with global numbers of over 500,000 people still dying every year, it’s not enough. So how do we critically challenge the status quo?

Now imagine taking this combined average data over a time frame, and combining it with accurate, real-time, personal dust monitoring. Imagine the changes you could make to process, controls, procedures and culture by seeing when and how the exposure is caused, where it was unacceptably high and, maybe, even warning people in real-time who unknowingly enter into the dangerous zone of this invisible killer.

If a smoke alarm goes off, you leave the building regardless of whether you see the fire. Why shouldn’t we apply the same theory, conscious response and swift action to slow and painful killers such as respirable dust?

Exposure is commonly expected in mining or engineered stone industries, however many more are unsuspectingly exposed in construction, demolition, quarrying, manufacturing, and more generally those in support functions in nearby offices and facilities within these industries and even people regularly using non-dust controlled roads.

The sad thing is, if the danger isn’t obvious (and dangerous levels of dust often aren’t as the most dangerous particles are usually the invisible ones), it’s too easy to ignore until the damage is done.

With real-time data, it’s easy to make decisions on measures that need to be taken to understand personal exposure levels and even have real time exposure warnings. Trolex is giving the power back to the people, companies and regulators to make informed decisions about protecting themselves and each other in the interest of saving lives.

If this drives changes in monitoring requirements, engineering controls such as dust suppression or RPE regulations can only benefit people and the families of those people who are currently exposed, all whilst minimising the risk of future exposure, and building precedence for the application of effective dust control measures in the hierarchy of control.

Here’s another thing: as a business or a responsible person, real-time monitoring and control is not only affordable and simple, but also accessible to everyone.

So, the question is, can you afford to not understand the problem?

Our aim is to give people the information, to save lives and increase awareness, and if you want to know more about our real-time fixed, portable or personal dust monitors (AIR XD Dust Monitor, XD ONE Portable Dust Monitor or XD1+ Personal Dust Monitor) then get in touch today.