With an estimated 1 million people dying globally from the inhalation of dust in occupational environments every year, now is the time to protect your workers. Personal and portable dust monitoring provides a simple solution for all workers at risk of dangerous dusk regardless of their application, processes or industry.

We’re continuously innovating our real-time dust monitoring technology to give you access to the information to effect change and keep your workers safe from hazardous respirable dusts. Which is why we have developed the XD1+ Personal Dust Monitor and the XD ONE Portable Dust Monitor.

Both products provide a unique approach to personal, handheld, portable dust monitoring. It’s dust monitoring that doesn’t get in the way, that’s small and versatile enough to give you the freedom to do your job whilst making zero compromise on accuracy and reliability, remaining easy to use, simple to maintain and cost effective.

Real-time monitoring offers solutions to us in our everyday lives. Whether it’s the real-time alerts that tells you that you’re at risk or in danger, or the subsequent data which provides you accurate information on what you’re monitoring, real-time monitoring has become an essential part of our lives.

But what about real-time monitoring when it comes to enhancing the workforce? You’d rely on real-time monitoring and alarms to tell you there’s a fire in your home, so why wouldn’t you rely on real-time monitoring to tell you if you were a risk as serious to your health at work? You’d rely on real-time data to tell you if you needed to track nutrition or health trends, so why wouldn’t you rely on essential data in real-time in the workplace?

Whether it’s for the health and safety of you and your colleagues, to better understand the processes and efficiency of the business, or just to help aid decisions, real-time monitoring can provide valuable data to workforces across a whole range of industries. Whether you are monitoring for hazardous substances like dust or silica, or monitoring for HAV, sound levels or proximity measures, real-time monitoring can enhance your workforce.

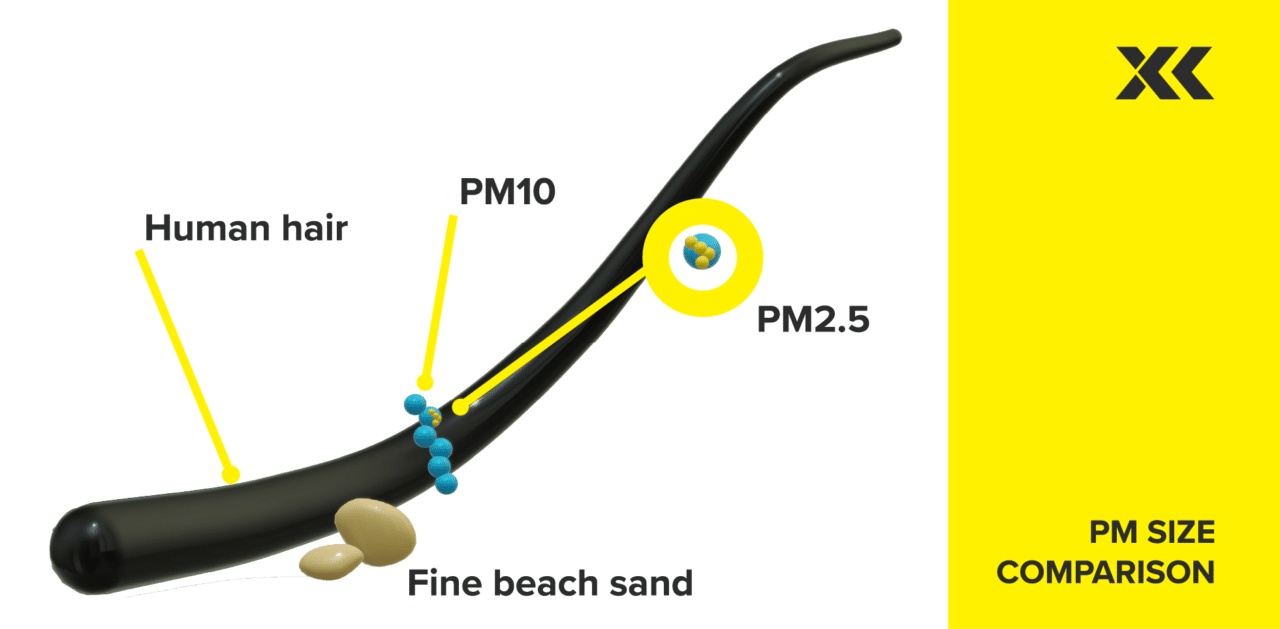

‘PM’ or particulate matter, also known as particle pollution is the term for a mixture of solid particles and liquid droplets found in the air.

It’s estimated that air pollution is linked to 43,000 deaths per year in the UK. Worldwide, at least 7 million people die each year from exposure to air pollution, with 91% of the worldwide population living in locations where the air quality exceeded the World Health Organisations (WHO) air pollution guidelines.

These guidelines state that that annual average concentrations of PM2.5 should not exceed 5 µg/m3 and PM10 should not exceed 15 µg/m3 (both for 24-hour periods). According to the WHO, ‘fine particulate matter at PM2.5 can penetrate through the lungs and further enter the body through the blood stream, affecting all major organs’. Exposure to dust at PM2.5 can cause serious disease to the respiratory system, such as lung cancer and COPD, and also can effect cardiovascular diseases, such as a stroke.

The image below demonstrates PM2.5 and PM10 size in comparison to a single human hair and a grain of sand.

The Department for Environment Food & Rural Affairs (DEFRA), the UK government ministerial department for environment protection, have also highlighted the severity of exposure to air pollution. This growing concern for the UK government estimated in 2010 that the cost of health impacts of air pollution was likely to exceed estimates of £8bn to £20bn.

Although between 2005 and 2022, the UK’s PM2.5 emissions decreased by 41%, emission levels have been relatively steady with small annual fluctuations in the last decade. Industrial combustion is a major source of PM emissions, as well as emissions from industrial production also playing a major part, which can be linked to heavy-dust industry where hazardous particulates can become airborne. Despite some reductions in PM emissions, the threat still very much remains.

A solution to this is real-time dust monitoring. Real-time particulate monitoring allows people in heavy dust loading environments, including industrial applications, to not only understand, but alert them instantaneously when they are exposed to dangerous levels of air pollution. For example, our AIR XD Dust Monitor can alert people in real-time when legislative levels of µg/m3 are breached, over a time-weighted average (TWA) 8-hour period, for both PM2.5 and PM10.

This technology not only offers a simple solution to individuals at high risk of exposure to air pollution by providing instant alerts, but also can help to prevent exposure in the future, as at-risk individuals can learn exactly when and where exposure to air pollution is highest and will likely occur. Thanks to real-time monitoring, both in the UK and Worldwide, we can reduce exposure to air pollution.

A manufacturer of prestigious natural stone, Burlington Stone have quarried for over 200 years across the English Lake District, extracting and crafting a diverse range of signature British natural slate and stone products.

Individuals across their workforce are often exposed to hazardous substances, most notably airborne dust, including silica dust. Burlington Stone trialed two XD1+ devices on their site for a month to see how real-time, personal dust monitoring would improve their safety processes.

After the trial, we spoke to Health and Safety Manager, Peter Walker, about the success of the trial and some of the major benefits which Burlington Stone’s workforce found deploying XD1+ Personal Dust Monitor units in their day-to-day processes.

With over 45 years of experience in the field of tunnelling, our partners, Timeco, are experts when it comes to tunnel boring machine (TBM), piling and foundation works, and other important activities involved in tunnelling. And when it comes to environmental monitoring for harsh tunnelling conditions, their partnership with Trolex has provided solutions to the entire tunnelling industry.

“We are satisfied with the 20+ years of cooperation with Trolex, as our official partner, because of the mutual trust in the innovative organisation and the reliability, user friendly

and durability of its products and solutions.” said Timeco, about the collaboration with Trolex to provide solutions to hazardous conditions in the tunnelling industry.

Trolex’s product range, provided to the tunnelling market in Europe by Timeco, includes a full range of dust monitoring technology, including AIR XD Dust Monitor and AIR XS Silica Monitor, as well as gas detection equipment, such as TX9165 Sentro 8 and TX6351-2 Sentro 1, detecting for a full range of hazardous gases.

You may have seen The All Party Parliamentary Group (APPG) for Respiratory Health report ‘Silica – the next asbestos’ released in March 2020?

In it, it states:

“Construction workers are still 100 times more likely to die from a preventable occupational disease than from an accident. We also know that approximately 12,000 deaths in the industry each year are linked to exposure to dust and chemicals.”

“Figures from IOSH show that roughly half a million people are exposed to RCS at work in the UK. They estimate that in Europe as a whole, 81% of these are employed in construction or in manufacturing products used in that industry.”

Experts at Trolex brought our new technology to the APPG’s attention and explained our nine-year silica detection R&D project that resulted in development of the new real-time silica monitor – work that we’d kept closely under wraps until mid 2021.

The original report refers to Workplace Exposure Limits (WELs) of dust. It says:

“Dust monitoring is vital. Technology advances mean that new methods of real-time exposure level monitoring are now possible. Knowing what the actual exposure levels are is important as exposure will depend on the actual task (e.g. cutting concrete is higher risk than breaking concrete, and the actual exposures depend on the concrete mixture).

“The new Code of Practice for Tunnelling […] that requires the use of new technology which is just becoming available and gives an instantaneous measurement.”

The instantaneous measurement the report refers to is the measurement of a variety of dust and particulates (something we already do with our AIR XD Dust Monitor and XD One Portable Dust Monitor, XD1+ Personal Dust Monitor products) – not specifically silica. Silica always being too difficult to uniquely identify.

Until now.

Our new silica-specific monitoring technology is a game changer.

By working with the authors of the APPG to share the features, benefits and thinking behind the new real-time silica monitoring technology they’ve been able to update the report with new advice on how to best protect workers from the dangers of respirable crystalline silica (RCS).

New studies from charity ‘Asthma and Lung UK’ (ALUK) found that lung disease deaths in the UK are the highest in Western Europe.

The staggering statistics have prompted an expanded approach towards research and development of lung diseases from ALUK.

ALUK’s studies show that cases of lung disease related deaths in the UK have been on the rise for the past 20 years.

It is reported that 500,000 people in the UK died from deaths relating to lung diseases over a seven-year period.

In 2018 alone, 84,721 respiratory deaths were recorded in the UK.

The charity has described the state of lung health in the UK as ‘shameful’, stating the need for improved research and development solutions to the problem.

After its relaunch in February, ALUK established a new five-year strategy upon the results of the study.

Lung diseases are currently the third most common cause of death in the UK and it’s currently costing the NHS £9 billion every year.

Despite this, lung-related health care is receiving less than 2% of public funding.

It is evident that the seriousness of lung problems in relation to other diseases is not taken as seriously, despite what we are seeing from the data.

A predominant factor in the poor state of the nation’s lung health is that people believe lung conditions aren’t life-threatening. This is a major misconception.

Through spreading awareness of how ‘shameful’ lung health is in the UK, this misconception can be dispelled.

ALUK aim to reduce lung disease deaths by 20% by 2027. When making everyone aware of these gruesome statistics, this can become a possibility.

The end goal is to provide support for everyone effected by all forms of lung disease.

ALUK’s solution to achieving this goal is through research and innovation.

Their aim is to expand their research and innovation programme so that £5 million is being invested into relevant research each year.

With the aim to “develop at least three new self-management tools” for 2 million people suffering with lung diseases, ALUK want to make training programmes and essential advice easily accessible to those who need it.

“By 2027, we will give 80% of people with lung conditions the opportunity to access our network of Breathe Easy support groups” states the ALUK Strategy to 2027.

With this, the strain on public healthcare is minimised and individuals are able to monitor their personal health through digitalised platforms and shared networks.

The statistics right now make for harrowing reading and harsh truths.

However, for ALUK, research and innovation is the solution for the future. By identifying the problem and acknowledging its severity and scale, goals can be achieved.

Through effective research and innovation lung disease deaths can become a thing of the past, not just in the UK, but worldwide.

Trolex are excited to be partnered with Active Environmental Solutions (AES), working together to protect workers from the dangerous and often irreversible consequences of occupational lung diseases caused by dust inhalation.

With AES’s specialist knowledge of occupational health and safety in Australian industries and Trolex’s leading safety technology, the opportunity of delivering solutions to prevent the dangers of dust inhalation for Australian workers, is not just a possibility, but now a reality.

AES want to spread awareness of the dangers of occupational lung diseases caused by dust inhalation. And in the case of dust monitoring, spreading awareness that new real-time dust monitoring technology to help prevent lethal occupational respiratory diseases now exists.

The opportunity to partner with Trolex was welcomed by AES, as it means that they can merge their expertise in occupational health using Trolex’s leading safety technology.

This creates the best solutions to their respective industries.

This simple message appealed to AES, and to Aleks Todorovic MSc, (OHP), Managing Director of AES’s team of Australian Occupational Safety experts at AES, as it aligned perfectly with the workers they seek to protect:

“Many businesses intuitively know the benefit of a broad threat detection – they just don’t know they know it, or perhaps how they go about implementing such devices – it’s our job to awaken that knowledge and show them there are new and effective dust detection technologies such as the Trolex AIR XD Dust Monitor, the XD ONE Personal Dust Monitor and most recently, the AIR XS Silica Monitor.

There are no arm twisting, or heavy sales techniques involved. Just a clear and simple presentation of responding to the facts.

Which is why Trolex and AES are working hard to provide further education to Australia’s mining, tunnelling, quarrying and construction industries, where workers are exposed to dangerous forms of respirable dusts.

This common goal of providing and expert knowledge and specialist equipment to these industries is the drive needed to inevitably reduce instances of occupational lung diseases to save lives.

Now, this collaboration will help to do exactly that.

The approach taken by businesses within these industries must now change. With new legislation on exposure to harmful dust in Australia, new dust monitoring methods are needing to be implemented.

Aleks said “As an occupational hygiene-minded business we know only too well the devastating effects inhaling respirable dusts can have on people’s long-term health.”

“That’s why we’re invested in the success and distribution of new and effective real-time dust monitoring technologies such as the Trolex AIR XD Dust Monitor, the XD ONE Portable Dust Monitor and the AIR XS Silica Monitor. These are lifesaving technologies that need to be included in their safety thinking” stated Aleks further.

By using Trolex’s advanced dust monitoring technologies, small changes can have a huge impact.

As the war on silica dust grows ever stronger by the day, more needs to be done.

With the reduction in exposure limits coming into effect across Australia, particularly hard on respirable crystalline silica (RCS), real-time monitoring for silica dust is a necessity, retaining live data and providing an instant alarm the legislated threshold is breached.

Whilst the ability to retrospectively assess levels of silica dust in facilities is available to industries where deadly silica dust is prevalent, the ability to monitor for silica dust in real time is not.

Trolex’s all new real-time silica monitor, the AIR XS, allows for accurate and reliable results demonstrating compliance with legislation. Aleks commented on this world-first technology:

“We are really excited to be a part of this project to be able to detect silica in real time. This will be the world’s first monitor to have this capability and we’re proud to be distributing it throughout Australia. The project was produced with the support of the Centre for Work Health and Safety in NSW proving just how important and potentially life-saving the new technology will be.”

And with the talk of real-time, wearable silica monitoring devices a possibility in the future, of course it makes perfect sense for all industries to be increasingly focused on detection possibilities.

Together, Trolex and AES are providing real solutions for real problems in Australia.

If you’d like to speak to one of our experts about integrating real-time dust monitoring technology into your working environment, then you can use the contact form below to get in touch with one of our experts today.

Reactec have been specialists in workplace health and safety environments for more than 15 years. Originally focusing on the damaging effects of exposure to vibration, they soon discovered that the most effective way of mitigating workplace risk lies in gathering as much data as possible.

As CEO Jacqui McLaughlin explains, “The traditional approach to health and safety that says ‘I can think about a problem, do a risk assessment and as a consequence of that assessment I can make it safe for people’, we prefer to go one step further and engineer out problems.

If we can measure what’s actually happening in the way of risk, then we can make workplaces a safer place to be.”

Starting with wearable hand/arm vibration monitoring technology to measure vibration exposure, Jacqui and her team quickly realised that the data management, hosting and reporting they provided their clients, was a powerful health and safety tool that could also be usefully applied to other workplace risks.

Rather than try to create new technology to measure a variety of risks, Reactec started to look for partners. Experts in their respective risk fields, whose work could be complemented by their data management technology.

“We see Trolex as a leading expert in how to measure dust and what we’re doing is providing a platform that makes the dust data they collect easy to access and meaningful.

We’re turning their data into meaning.”

“We take the data associated with a process so that your records don’t just look like a bunch of numbers, but they tell you about who was doing what and where. And as you build up more data, you can get more intelligence in terms of process and people and where you need to put in your biggest efforts to get safer environments.”

With new dashboard integration and development soon to be rolled out to a live Trolex XD ONE Portable Dust Monitor client, things are moving fast.

Complementary technology that gives the simple to use and easy to integrate Trolex XD ONE, and Reactec a fast-track route into the world of actionable dust monitoring intelligence.

“And there’s an overlay angle,” says Jacqui.

“With our tech we get information on vibration. We have other tech that gives us information on noise. And if you start overlaying all of that data with dust data and also situational location information, you can create a health risk passport for an individual or a site. It’s the very start of an exciting journey that will provide more and more useful data as clients understand what they can do with the data over time.”

Reactec and Trolex; a marriage made in data and a powerful collaboration that looks set to flourish in the future. Plans are already afoot to take things to the next level with new bluetooth, IoT data recording and cloud-based analytics.

Get in touch today for more information on how you can get the most insightful analysis on your worker health and safety.

Based in Salford, M&E contractor Thermatic Homes has more than 70 electricians out in the field rewiring properties for social housing providers including The Wates Group, Unitas, Brunswick Regeneration and Bolton at Home. As an ex-electrician himself, Thermatic MD Karl Wallace is aware of the dust challenges their work creates.

“There are a lot of issues created by dust,” he says. “Chasing through to the brickwork and masonry is extremely intrusive and there’s a huge amount of dust created. We’re conscious that it’s potentially a dangerous environment if not controlled properly.”

Which is why Thermatic electricians always use dust extraction on their CHASE machines. Why they always wear dust masks, always screen doors and why they always hoover, clean, and spray the air with water.

Unlike a traditional building site, it’s not possible to saturate the air in people’s homes with water.

“It’s never ideal,” says Karl, “and being an ex–electrician myself, who’s rewired many a house, you always want to do more. Year on year as more information comes out about the harmful effects of dust, we’re increasingly aware of the dangers and want to do everything we can to prevent them.”

Which is why, when Karl was introduced to the XD One by Trolex MD Steve Holland, he was so keen to get it out on site to trial for dust detection. “What a wonderful idea!” says Karl. “It looks perfect.”

After all, what better way to instantly identify the dust threat than with accurate, real-time dust monitoring and readings? Even better that they’re available on wearable devices his team can just clip on as they work.

A real-time reading of the room designed not just to protect Thermatic workers but also to gain a clear understanding on dust levels that might impact on customers, too.

As important as the XD ONE Portable Dust Monitor is in protecting workers and tenants, using it also sends a very clear message to the industry, not just from Thermatic, but also from the main contractors Thermatic work for.

Very much a “we go above and beyond” message, any main contractor can be rightly proud to do their bit in helping to prevent the 12,000 deaths a year from workplace respiratory disease by using Thermatic and Trolex XD ONE Portable Dust Monitor.

It’s a pioneering approach in the construction industry that really prioritises health and safety and makes clear the commitment to worker and customer safety.

With the XD ONE now onsite as part of a pilot phase to monitor rewiring and upgrade projects, we’ll be reporting back very soon.

Says Karl, “I’m really looking forward to seeing what kind of data the XD ONE gives us, the degree of harm it detects and what we can do about it.”

In the meantime if you want any more information on how the XD ONE can keep your workers and customers safe from the dangers of avoidable dust and particulate inhalation get in touch today.